Silicone oil fan clutch heat dissipation performance analysis method based on finite elements

A technology of heat dissipation performance and analysis method, applied in geometric CAD, sustainable transportation, design optimization/simulation, etc., can solve problems such as excessive rotation speed, reduced torque transmission capacity of silicone oil fan clutch, complicated structure of silicone oil fan clutch, etc. Guaranteed accuracy and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

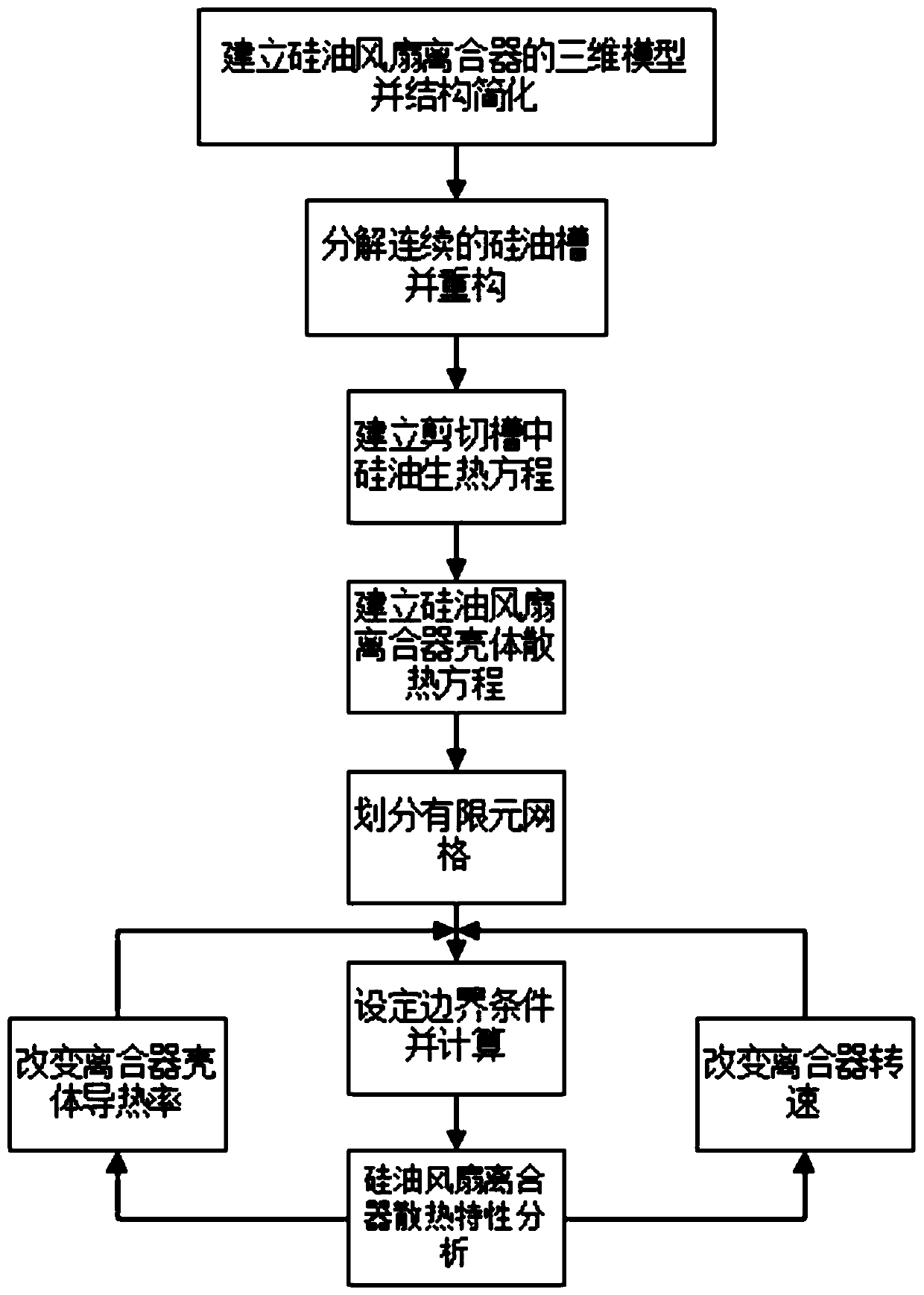

[0039] Such as figure 1 As shown, the finite element-based analysis method for the heat dissipation performance of the silicone oil fan clutch includes the following steps:

[0040] (1) Establish a three-dimensional model of the silicone oil fan clutch and simplify its structure:

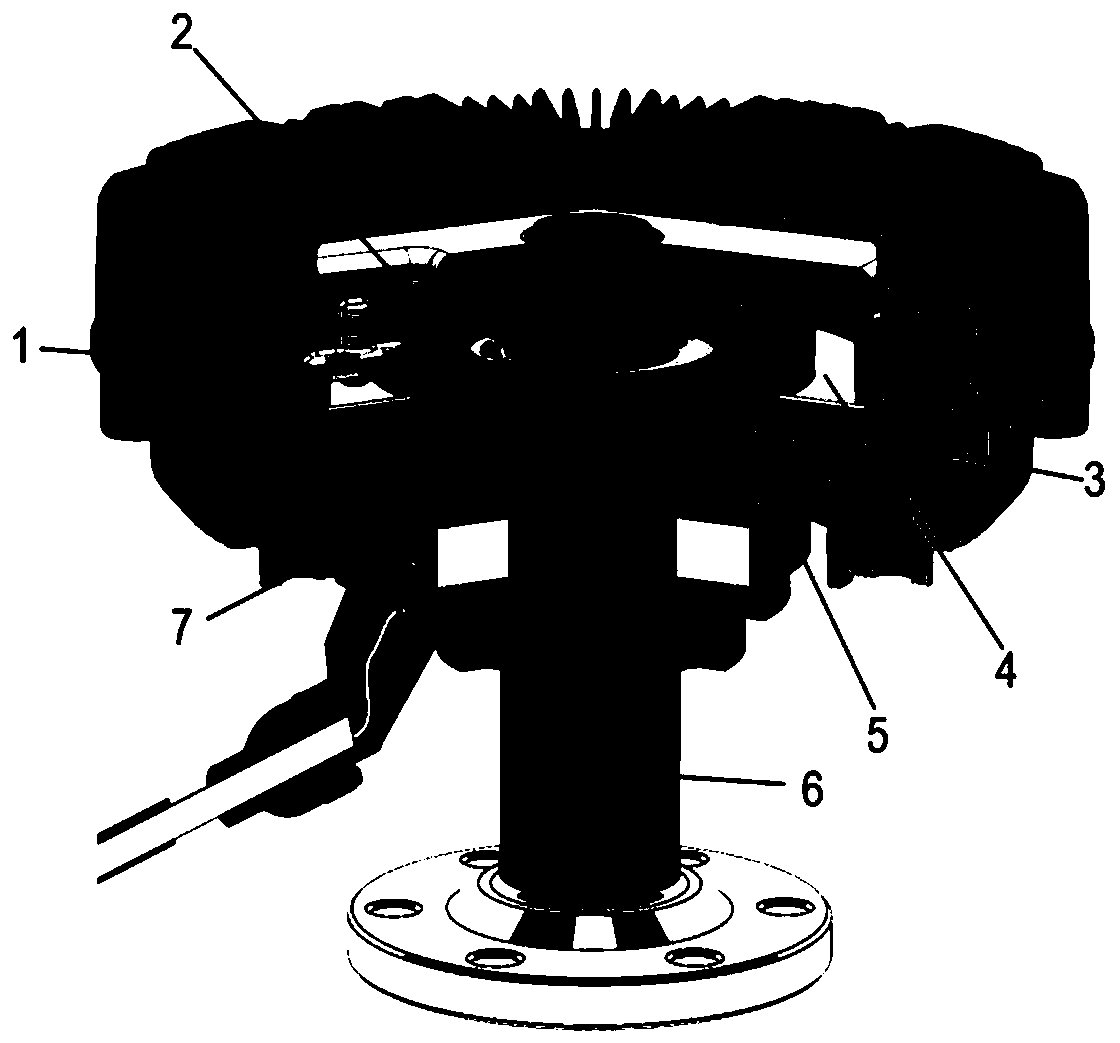

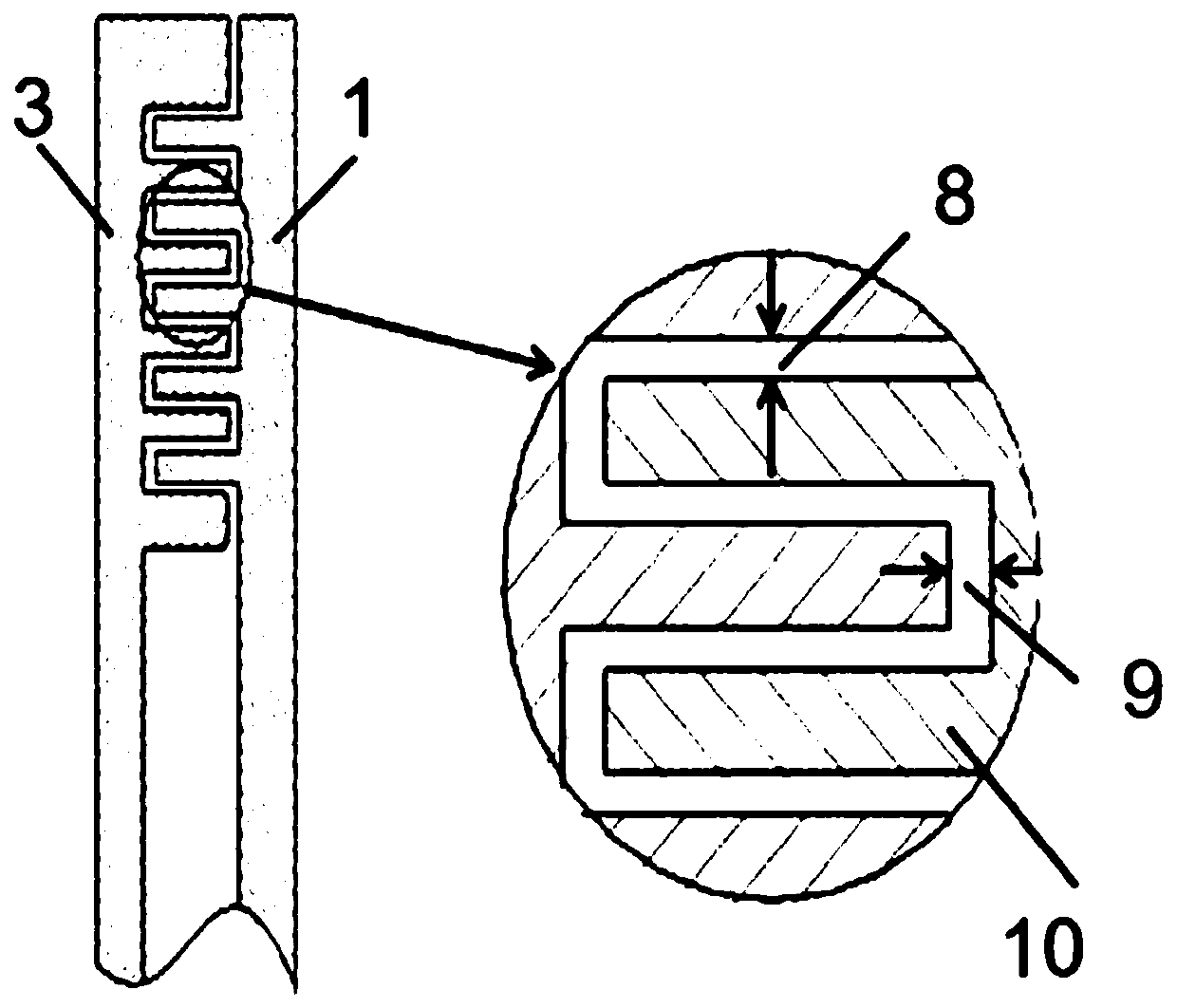

[0041] The three-dimensional model of the silicone oil fan clutch is established by three-dimensional modeling software, and simplified on the basis of the model. Since the present invention only analyzes the temperature characteristics of the clutch housing, the driving disc, the driven disc and the silicon oil, the modeling will figure 2 The drive shaft 6, bearing 7, oil storage chamber baffle plate 4, coil 5, spring leaf 2 and other parts irrelevant to torque transmission are removed, lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com