Modeling and analyzing method of interlaced and laminated mixed laminated composite material laminated board

A technology of composite material layer and analysis method, which is applied in the field of automatic generation of interwoven and laminated hybrid laminated composite material laminates, to achieve the effect of reducing scientific research costs and improving the ability to resist delamination and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Attached below picture with The examples further describe the present invention, and it should be understood that the following examples are intended to facilitate the understanding of the present invention, but do not limit it in any way.

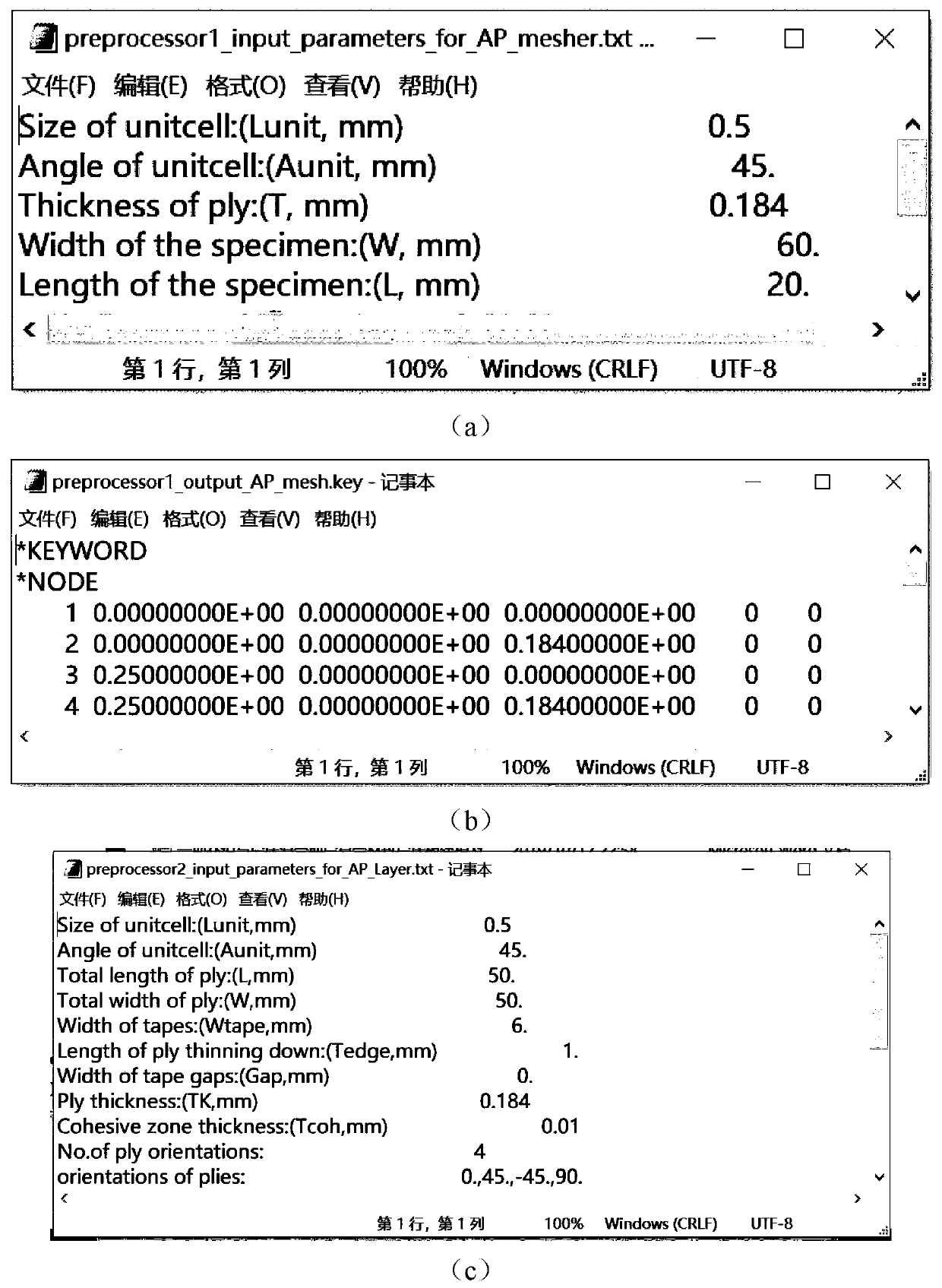

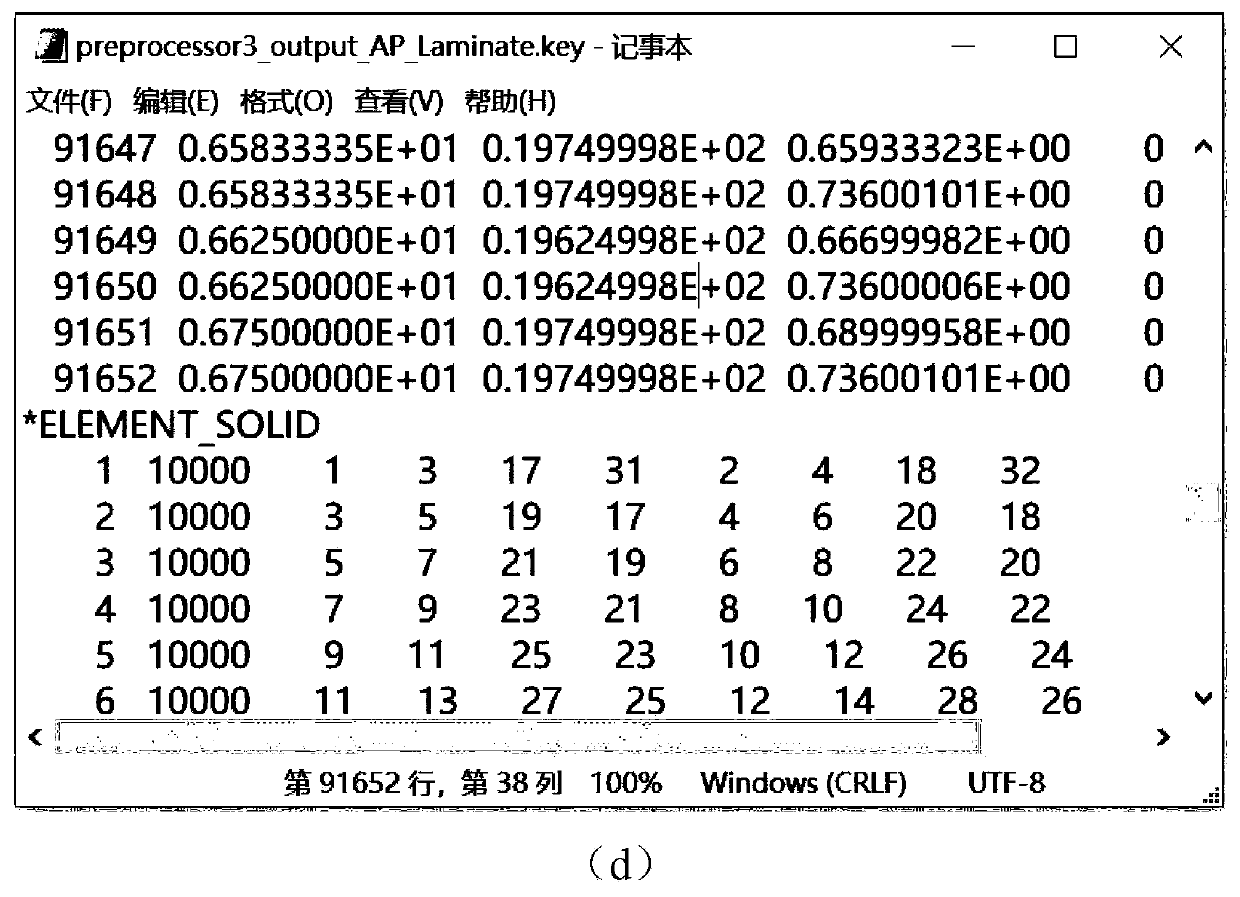

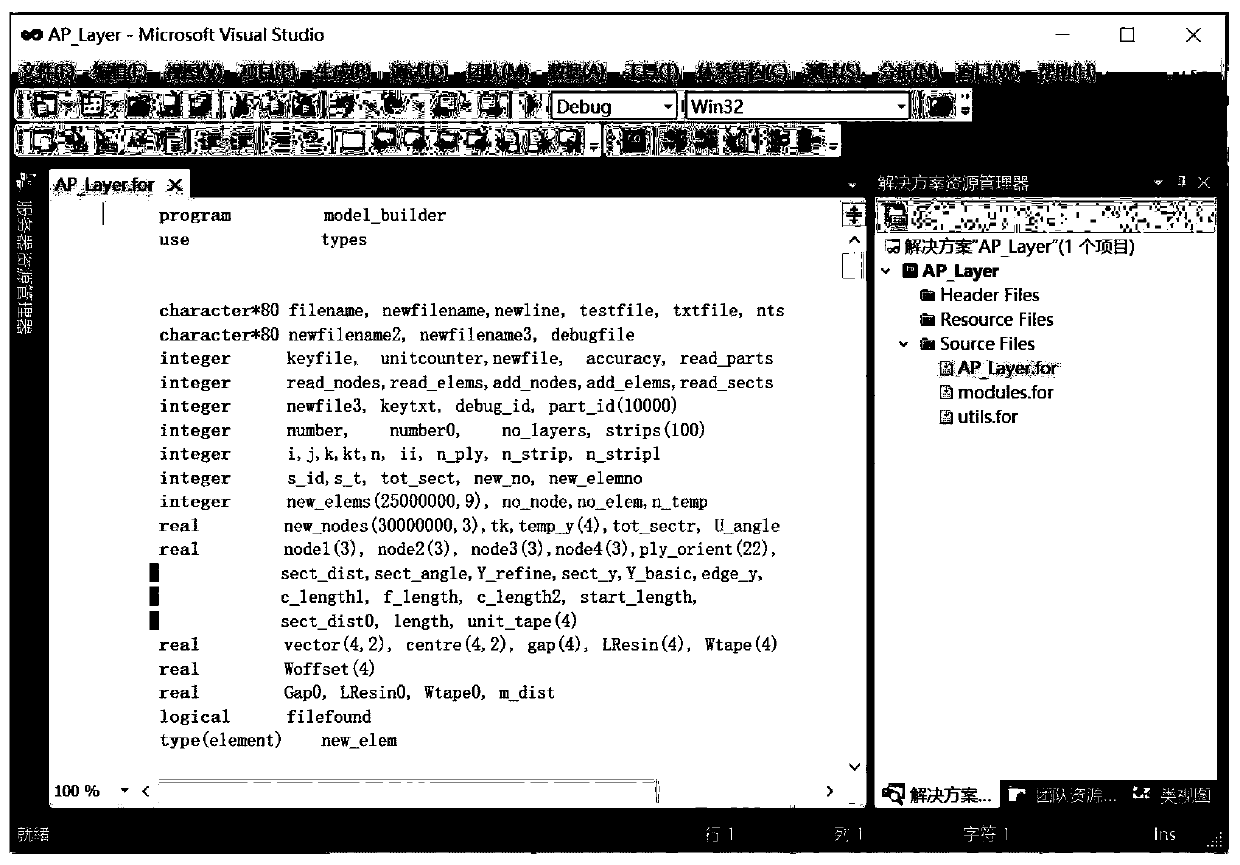

[0041]The present invention adopts the parametric automatic modeling tool to automatically generate the finite element model of the LS-Dyna data format of the composite material laminate, wherein the parametric automatic modeling tool adopted comprises three major functional blocks: model grid generation toolkit, model Build Toolkit and Performance Prediction Toolkit. The model parameters in the present invention can be exported into files in other formats, and at the same time interface with other grid division, finite calculation and post-processing software, such as HYPERMESH, ABAQUS and ANSYS. The user first inputs parameters such as grid size, model size, ply thickness, ply sequence, fiber bandwidth, ply position, etc. into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com