Aluminum electrolytic capacitor and preparation method thereof

A technology for aluminum electrolytic capacitors and aluminum layers, applied in capacitor terminals, capacitor parts, etc., can solve problems such as pressure riveting or thorn riveting that does not meet the requirements, and achieve small contact resistance, large conductive channels, and ripple current resistance powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

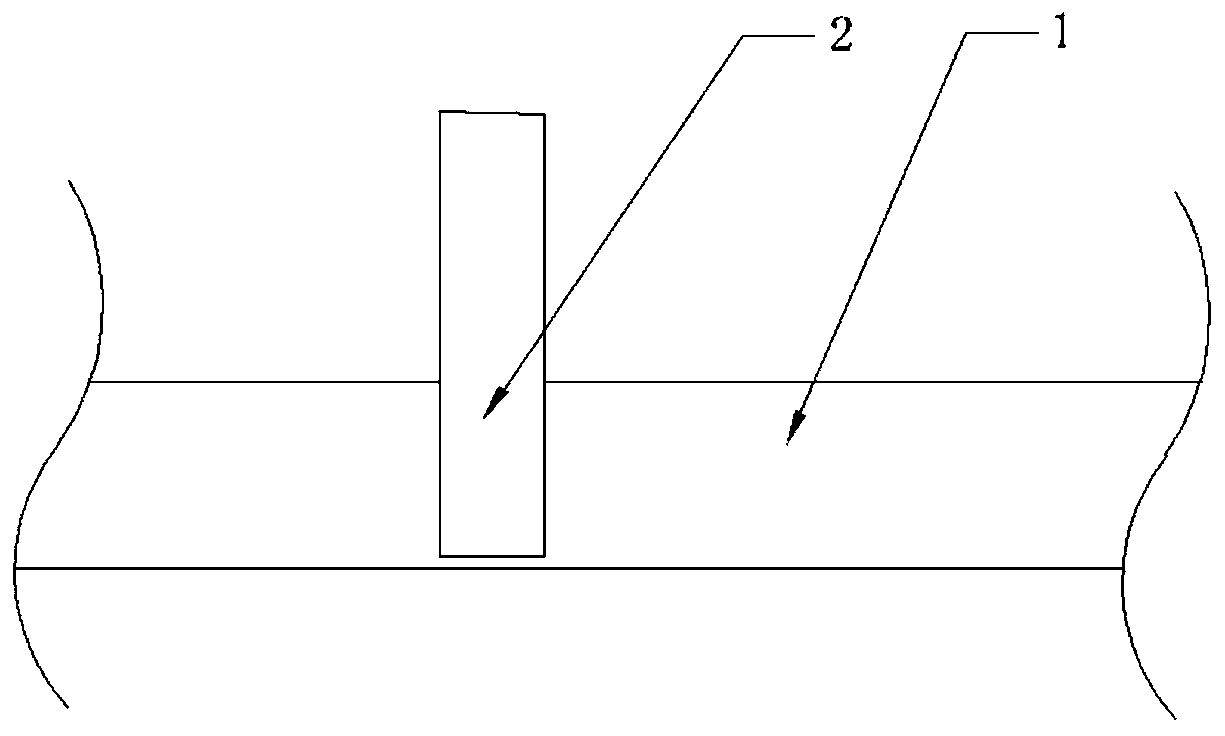

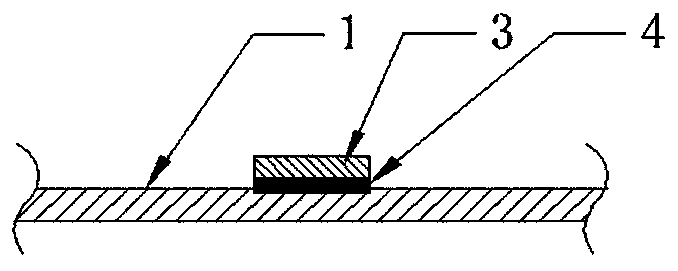

[0026] An aluminum electrolytic capacitor, including a casing and a core package, the core package is sealed in the casing by a rubber plug, the core package is formed by winding an anode foil, electrolytic paper and a cathode foil 1, and the anode foil and the cathode foil 1 are respectively riveted with an anode The foil guide strip and the cathode foil guide strip 2; the anode foil guide strip includes an aluminum foil substrate 3 and a sintered aluminum layer 4, and the riveted surface of the aluminum foil substrate 3 and the cathode foil 1 is sintered with a sintered aluminum layer sintered by aluminum powder or aluminum alloy powder. The thickness of the sintered aluminum layer is 10-500 μm. The porosity of the sintered aluminum layer on the cathode lead foil strip 2 is between 10% and 50%, and the sintered aluminum layer on the cathode lead foil strip is embedded in the cathode foil so that the cathode lead foil strip and the cathode foil are in close contact.

[0027] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com