Direct torque control system and method for transverse flux switched reluctance motor

A technology of switched reluctance motor and direct torque control, which is applied in the direction of electronically commutated motor control, control system, vector control system, etc. Torque ripple operation problem, good operating condition level, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

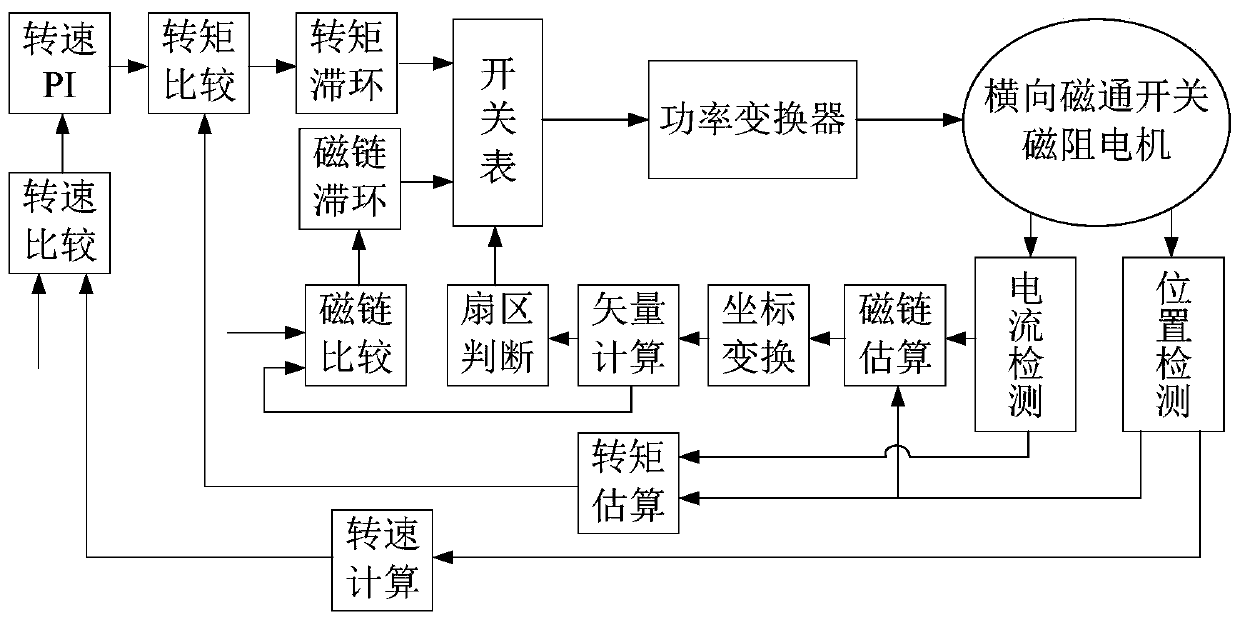

[0033] The invention uses direct torque control to control a four-phase transverse flux switched reluctance motor through a given torque, so as to further reduce the torque ripple effectively while increasing the torque density.

[0034] From image 3 It can be seen from the figure that information such as phase current i and rotor position angle θ of the transverse flux switched reluctance motor during operation will be fed back to the control system, and then the known phase current i and rotor position angle θ can be obtained by looking up the table Calculate the flux linkage and torque of each phase of the motor. Then through the transformation, the flux vector amplitude ψ of the motor can be obtained S , the vector angle δ and the total electromagnetic torque T. Then the magnitude of the flux linkage vector ψ S and the total electromagnetic tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com