Boiling-resistant konjac glucomannan noodles and making method thereof

A technology of konjac glucomannan and noodles, which is applied in the fields of noodles and its preparation, boil-resistant konjac glucomannan noodles and its preparation, which can solve the problems that Chinese medicine ingredients are not applicable to all groups of people and have low market value, and achieve a good market Effects of foreground, immunity booster, crystal clear appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

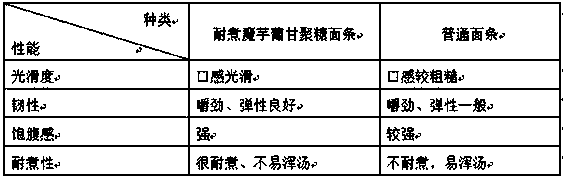

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of preparation method of boiling resistant konjac glucomannan noodles comprises the following steps:

[0024] ① Prepare konjac glucomannan sol: prepare a KGM aqueous solution with a KGM mass fraction of 1%~2% at room temperature, stir at a speed of 400r / min for 3 hours, and use a pH agent to adjust the pH value to 7.0 to obtain a KGM sol;

[0025] ②Carboxylation of KGM: Add sodium periodate into KGM sol at a mass ratio of 1:1, stir at 30°C for 1 hour under shading at 500 r / min, and then add excess ethylene glycol to react and remove excess sodium periodate. After 3 days of dialysis, take the supernatant, freeze-dry (-80°C, -50psi) to obtain a xerogel, and pass through a 200-mesh sieve after ultrafine grinding to obtain carboxylated KGM particles;

[0026] ③ Konjac glucomannan cross-linked sol: KGM and carboxylated KGM particles were dissolved in pure water at a mass ratio of 1:1 to obtain a total mass fraction of 1% konjac glucomannan cross-linked so...

Embodiment 2

[0032] Embodiment 2 A preparation method of boil-resistant konjac glucomannan noodles, comprising the following steps:

[0033] ① Prepare konjac glucomannan sol: prepare a KGM aqueous solution with a KGM mass fraction of 1%~2% at room temperature, stir at a speed of 400r / min for 3 hours, and use a pH agent to adjust the pH value to 7.0 to obtain a KGM sol;

[0034] ②Carboxylation of KGM: Add sodium periodate into KGM sol at a mass ratio of 1:1, stir at 30°C for 1 hour under shading at 500 r / min, and then add excess ethylene glycol to react and remove excess sodium periodate. After 3 days of dialysis, take the supernatant, freeze-dry (-80°C, -50psi) to obtain a xerogel, and pass through a 200-mesh sieve after ultrafine grinding to obtain carboxylated KGM particles;

[0035] ③ Konjac glucomannan cross-linked sol: KGM and carboxylated KGM particles were dissolved in pure water at a mass ratio of 1:1 to obtain a total mass fraction of 2% konjac glucomannan cross-linked sol;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com