A method for repairing the performance of three-proof and easy-to-decontamination tooling fabrics

A repair method and easy decontamination technology, which is applied in the treatment of anti-coloring pollution/anti-fouling fibers, textile materials, removal of liquid/gas/steam, etc., and can solve unqualified performance indicators, strong water and oil repellency, and waterproof , anti-oil, decontamination and other problems, so as to avoid economic loss, enhance safe operability and improve permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A three-proof performance of tooling fabric easy decontamination repair method, comprising the steps of:

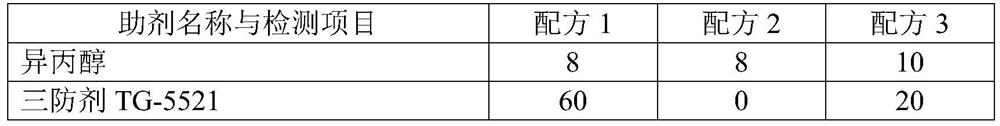

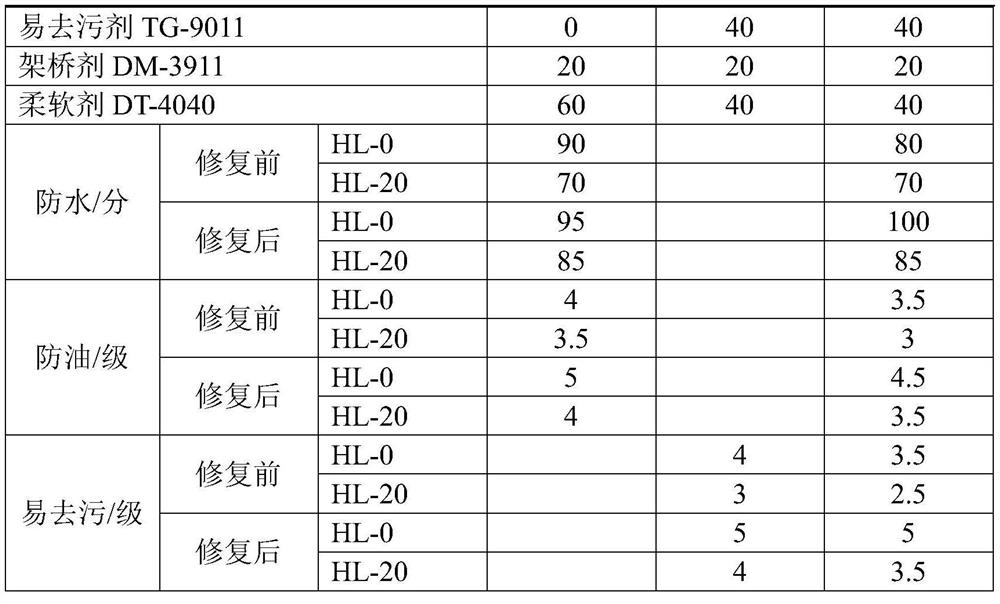

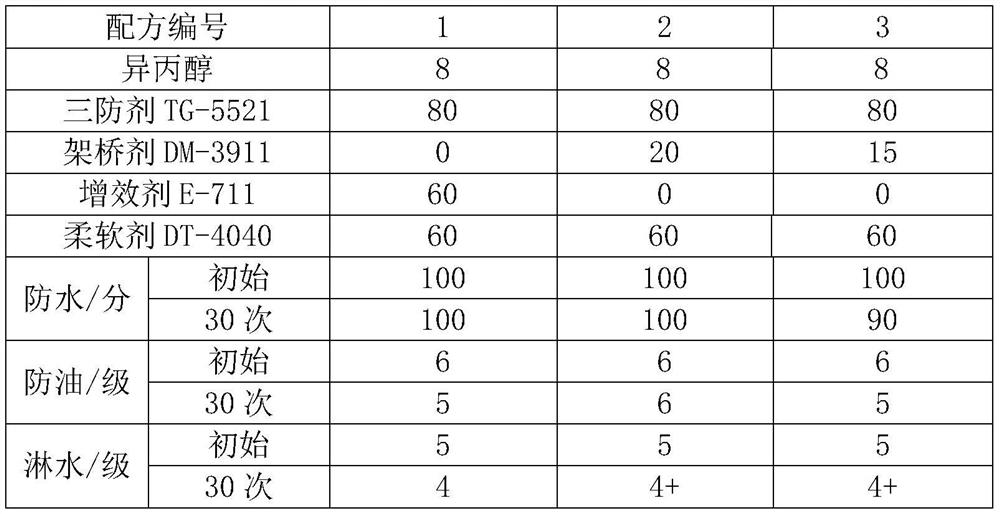

[0029] Preparation adjuvants: parts by mass, 9 parts of isopropanol prepared, 30 parts of the three anti-TG-5521,60 agent, stain release TG-9011,50 parts parts parts crosslinking agent DM-3911,70-modified fatty acid ester class softener DT-4040.

[0030] A, prepared aid solution: adjuvant with water ratio of 1: 5 were mixed to obtain a solution adjuvants, the adjuvant solution was divided into 3 parts, respectively, additives I, II additives, auxiliaries III ;

[0031] B, repair process: to be repaired three anti easy decontamination tooling fabric at a normal temperature and pressure drum dyeing machine, at room temperature, adding additives I, treatment 10min, then adding additives II, treatment 10min, then adding additives III, processing 10min, and then heated at / min temperature increasing rate of 1 ℃ to 40 ℃, heat treated for 30 min;

[0032] C, will process: St...

Embodiment 2

[0034] A three-proof performance of tooling fabric easy decontamination repair method, comprising the steps of:

[0035] Preparation adjuvants: parts by mass, to prepare 8 parts isopropanol, 20 parts of the three anti-TG-5521,40 agent, stain release TG-9011,40 parts parts parts crosslinking agent DM-3911,40-modified fatty acid ester class softener DT-4040.

[0036] A, prepared aid solution: adjuvant with water ratio of 1: 4 were mixed to obtain a solution adjuvants, the adjuvant solution was divided into 3 parts, respectively, additives I, II additives, auxiliaries III ;

[0037] B, repair process: to be repaired three anti easy decontamination airflow dyeing machine tooling fabric is placed in the drum, at room temperature, adding additives I, treatment 10min, then adding additives II, treatment 10min, followed by addition of adjuvants III, treated 10min, then / min ramp rate of 1 ℃ warmed to 40 ℃, heat treated for 30 min;

[0038] C, will process: Step B to be treated to repair ...

Embodiment 3

[0040] A three-proof performance of tooling fabric easy decontamination repair method, comprising the steps of:

[0041] Preparation adjuvants: parts by mass, to prepare 10 parts of isopropyl alcohol, 20 parts of the three anti-TG-5521,40 agent, stain release TG-9011,20 parts parts parts crosslinking agent DM-3911,40-modified fatty acid ester class softener DT-4040.

[0042] A, prepared aid solution: water with additives were mixed in a 1:10 ratio, to obtain a solution adjuvants, the adjuvant solution was divided into 3 parts, respectively, additives I, II additives, auxiliaries III ;

[0043] B, repair process: to be repaired three anti easy decontamination tooling fabric at a normal temperature and pressure drum dyeing machine, at room temperature, adding additives I, treatment 10min, then adding additives II, treatment 10min, then adding additives III, processing 10min, and then heated at / min temperature increasing rate of 1 ℃ to 40 ℃, heat treated for 30 min;

[0044] C, will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com