Charger mainboard test equipment for simulating Qi standard wireless charging by using real coil

A technology for wireless charging and testing equipment, applied in electronic circuit testing, instruments, measuring electricity, etc., can solve the problems of unguaranteed product quality, unavailability of charging communication testing, and increase of scrap rate, etc., to meet the requirements of rapid testing and testing functions. Improve and improve the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The invention adopts real coils to simulate the test of the main board of the Qi standard wireless charging charger.

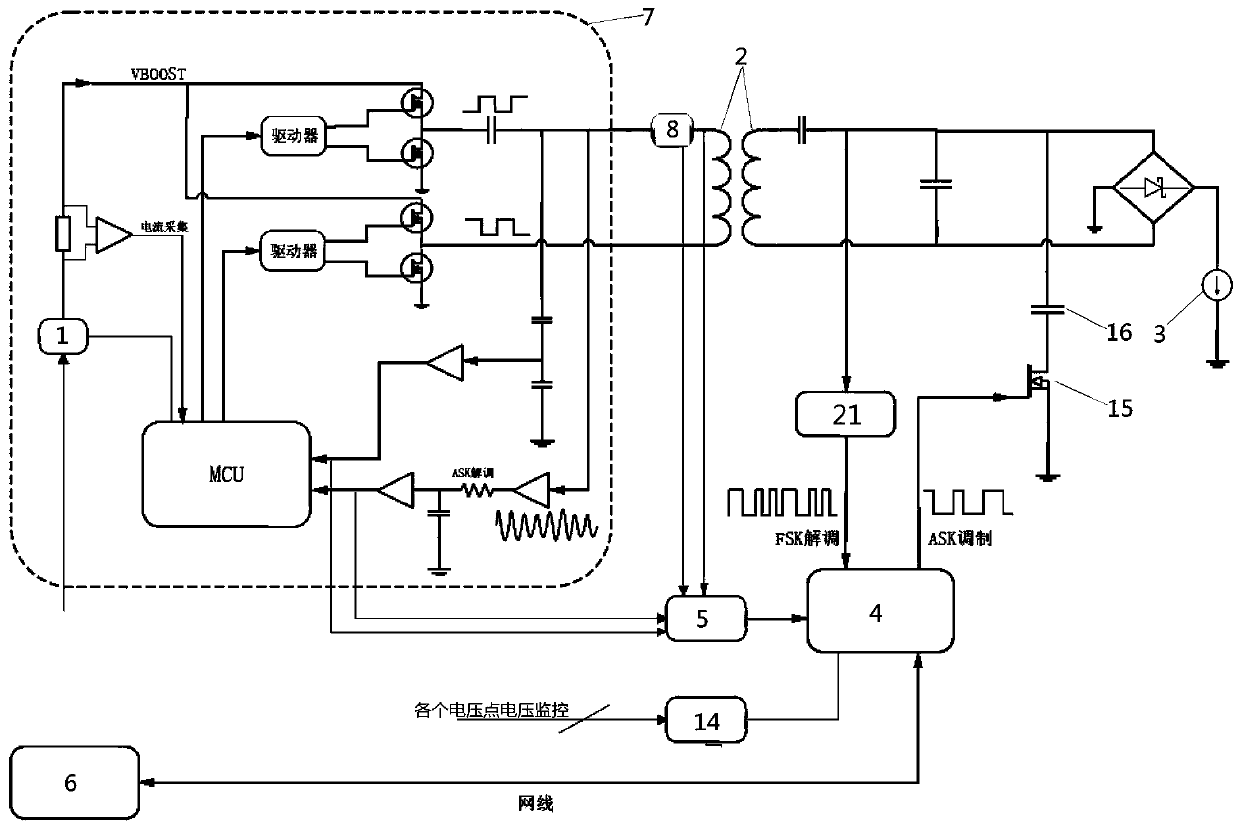

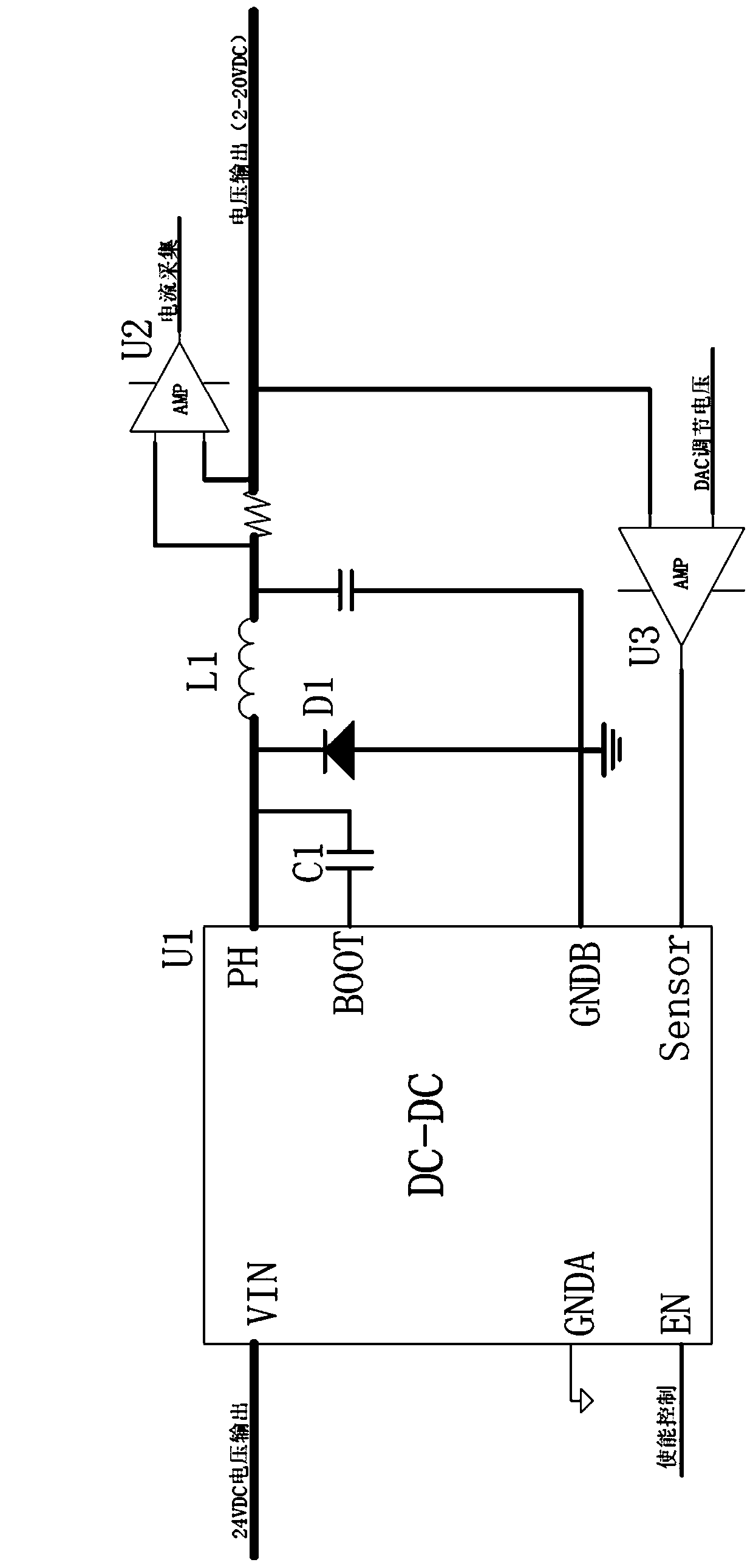

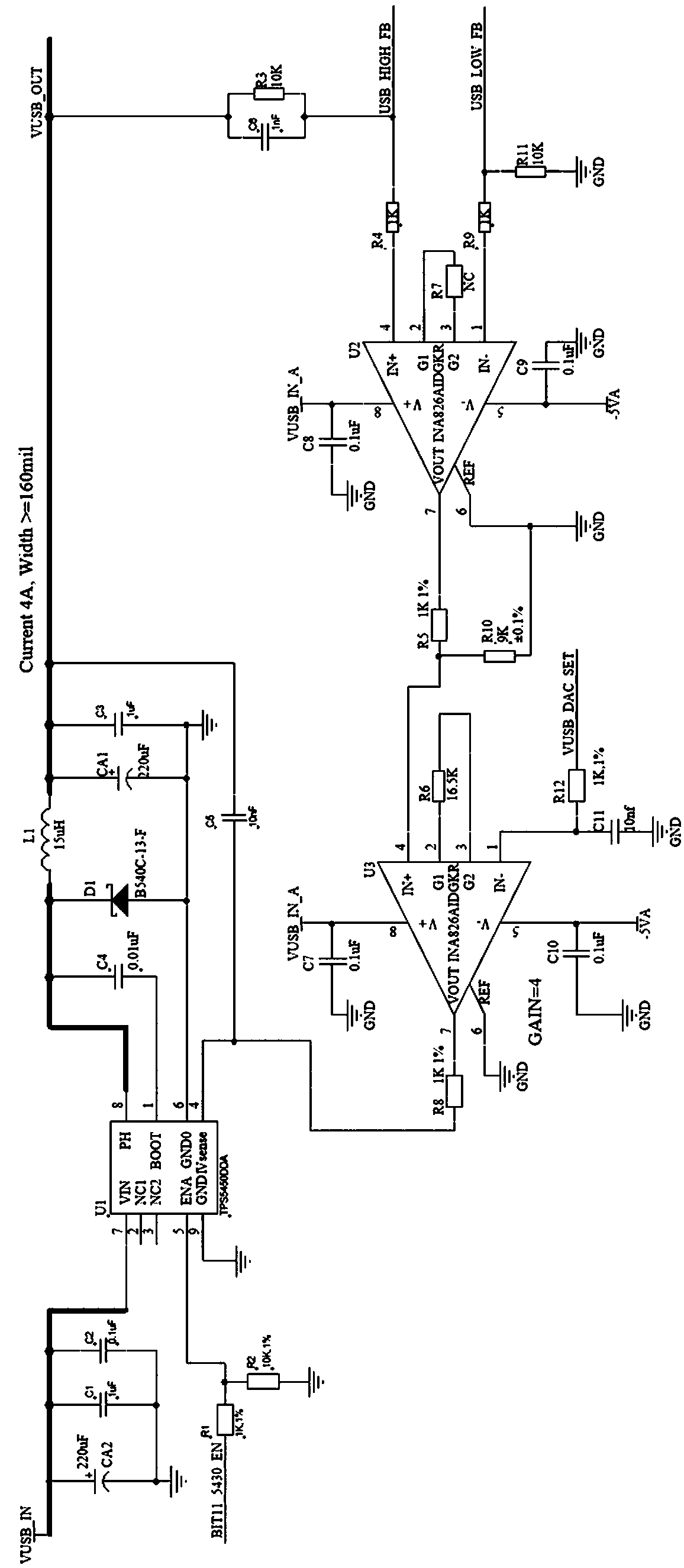

[0064] Such as figure 1 As shown, the present invention includes a power supply module 1, a sending and receiving coil 2, an electronic analog load 3, an FPGA 4, several functional test modules, a high-speed ADC acquisition module 5 and a peripheral host computer 6. The power module 1 powers on the entire test equipment and the main board 7 of the charger to be tested. Such as figure 2 and image 3 As shown, the power supply module 1 is composed of a DC-DC module, LC resonance, and DAC feedback voltage regulation. The 24V power supply is input to the DC-DC module, and at the same time, the output of the DC-DC module is controlled by enabling. After LC resonance, The output voltage is 2-20V, and the DAC feedback voltage regulation will input the peripheral feedback to the DC-DC module, and the DC-DC module will output the required voltage according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com