Low-quantum-loss sheet laser and laser output method thereof

A thin-sheet laser and thin-sheet technology, applied in lasers, phonon exciters, laser components, etc., can solve problems such as deterioration of laser stability, deterioration of laser output beam quality, and limitation of laser output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

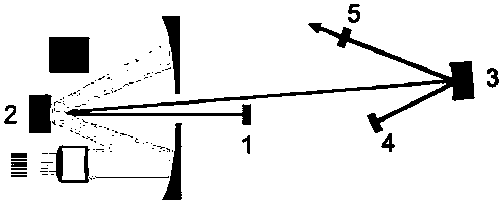

[0019] see figure 1 , the low quantum defect sheet laser of an embodiment provided by the present invention includes: 1-dichroic mirror (1030nm high reflection, R(1048nm)<45%), 2-the second sheet gain module, 3-the first sheet Gain block, 4-high reflection mirror, 5-coupled output mirror.

[0020] Specifically, in an implementation manner, the dichroic mirror 1 , the first slice gain module 3 , and the second slice gain module 2 constitute a first resonant cavity. 940nm LD is used to pump the second sheet gain module 2, the dichroic mirror 1 is highly reflective to the 1030nm laser beam and the transmittance to the 1048nm laser beam is greater than 55%, so that the 1030nm laser beam is in the first resonant cavity The repeated oscillation increases the laser power density of the laser beam, and the laser beam is absorbed by the first sheet gain module 3 during the repeated oscillation, so that the number of laser particles is reversed.

[0021] Specifically, in an embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com