X-ray grating monochromator for high repetition frequency free electron laser

A high repetition frequency, X-ray technology, applied in the field of X-ray optical instruments, can solve the problems of grating affecting grating resolution, grating damage, inapplicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

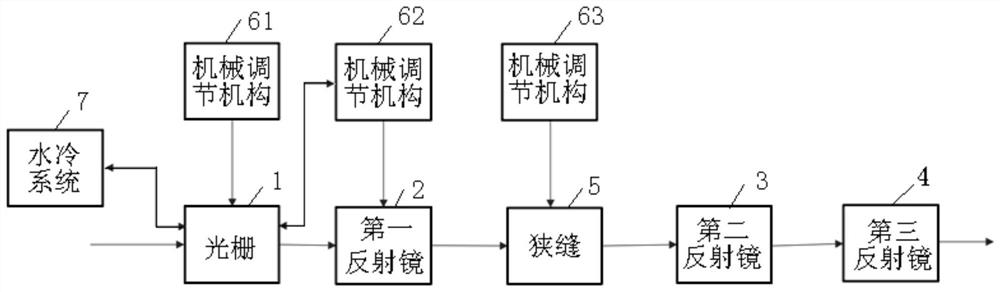

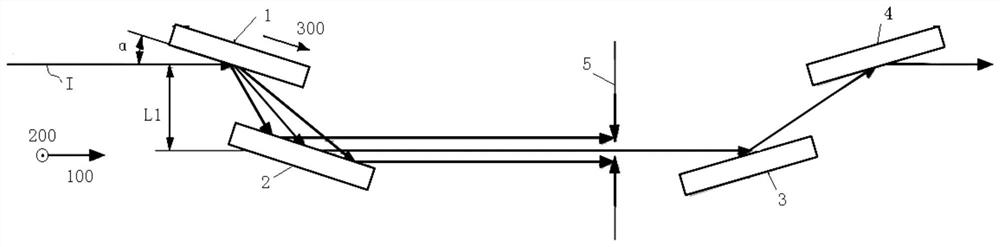

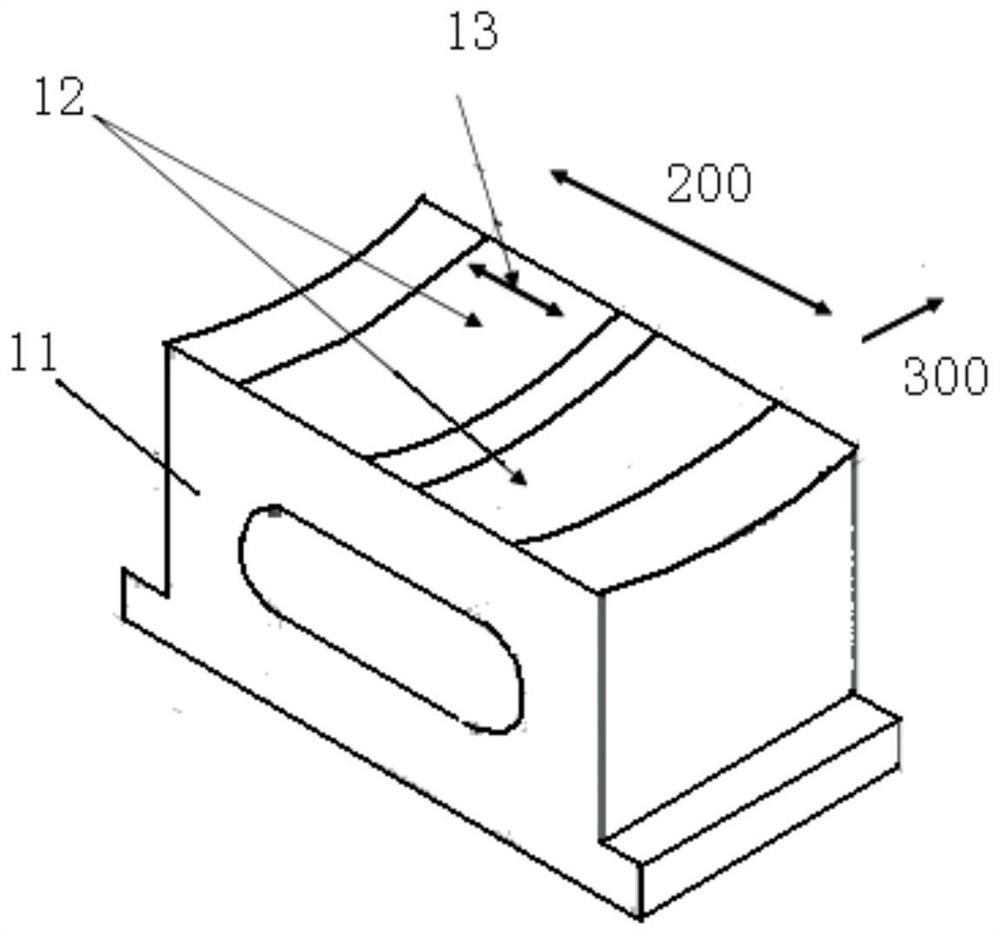

[0023] Such as figure 1 Shown is a connection diagram of an X-ray grating monochromator for high repetition frequency free electron laser according to an embodiment of the present invention. figure 2 is like figure 1 Schematic diagram of the structure of the X-ray grating monochromator for high repetition rate free electron laser shown. The X-ray grating monochromator is based on a movable grating, in this embodiment it is based on a movable cylindrical variable pitch grating.

[0024] Such as Figure 1-Figure 2 As shown, the X-ray grating monochromator for high repetition frequency free electron laser of the present invention is installed in a high energy free electron laser device, and it comprises: along the direction of the optical path of the incident light of a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com