High-water-retaining hydrophilic core and manufacturing method thereof

A production method and a hydrophilic technology, which are applied in the field of high water-retention hydrophilic cores, can solve the problems of poor resilience, poor softness, and poor comfort, and achieve less liquid re-seepage, improved dryness, and less contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

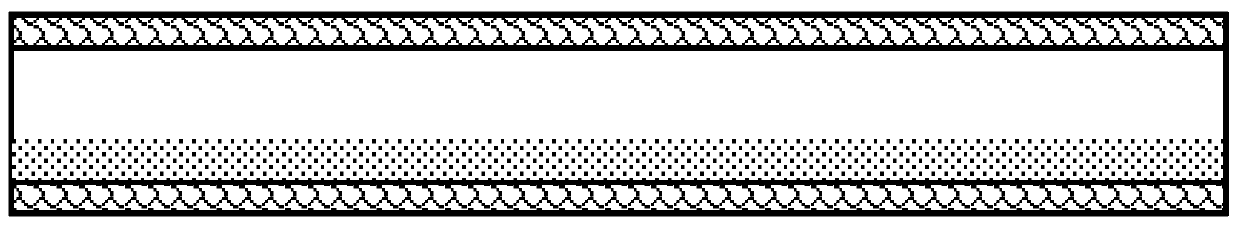

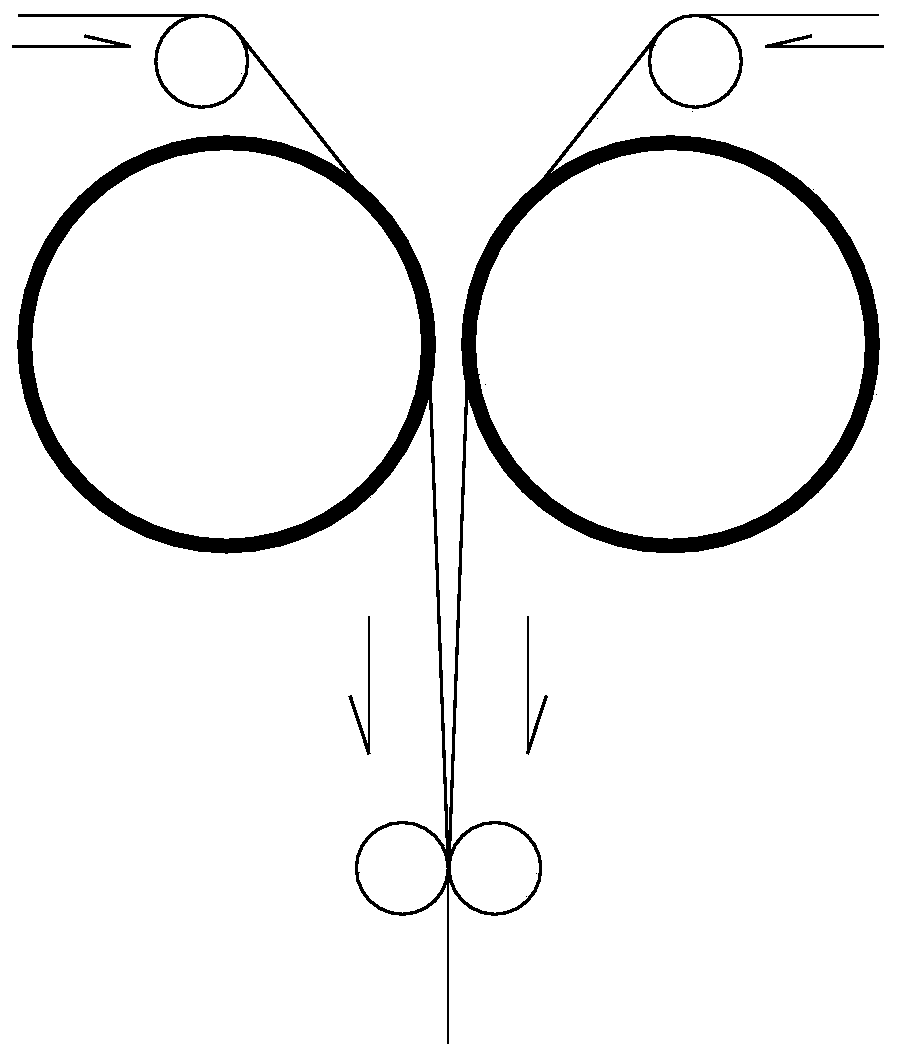

[0038] by figure 1 As an example, the further description of the production method of the high water retention hydrophilic core of the present embodiment is as follows:

[0039] 1) Prepare a hydrophilic hollow cylinder with EPE; (EPE (Expandable Polyethylene), is expandable polyethylene, also known as pearl cotton. It is a non-crosslinked closed-cell structure, and it uses low-density polyethylene (LDPE) as the main raw material High-foamed polyethylene products produced by extrusion. Because it is a completely independent cell body, it is light, flexible, and can be bent to absorb impact force, disperse, and have a cushioning effect, which overcomes the fragility, deformation and recovery of ordinary styrofoam. shortcoming).

[0040] 2) Seal one end of the hollow cylinder; the sealing method can be heat pressing, bonding, etc.

[0041] 3) filling SAP / SAF in the hollow cylinder;

[0042] 4) Close the other end of the hollow cylinder.

[0043] Wherein, after step 1), 2) or ...

Embodiment 2

[0045] This embodiment is an improvement of Embodiment 1, adding POE material to the EPE material to prepare a soft and hydrophilic hollow cylinder.

Embodiment 3

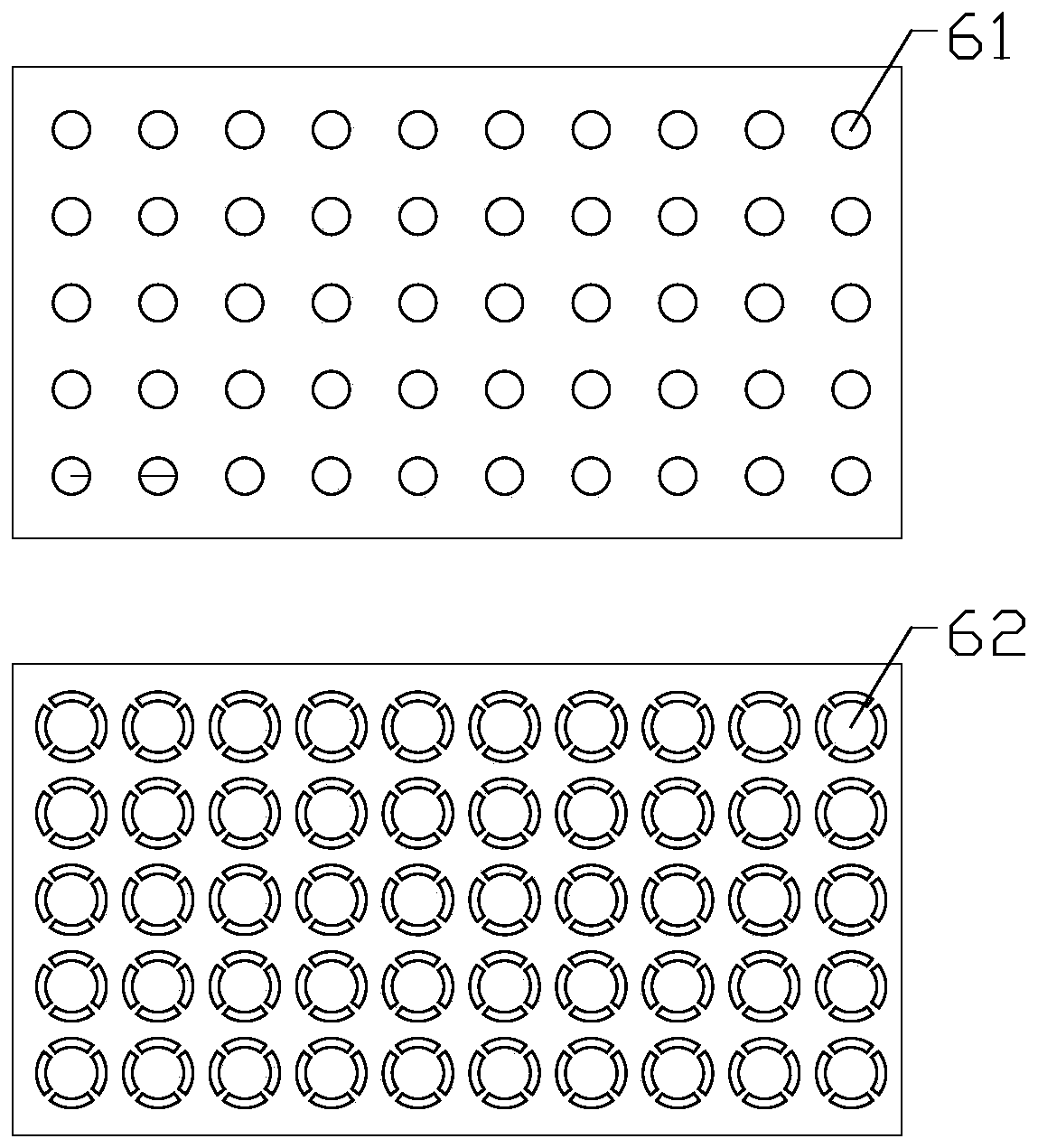

[0047] This embodiment is an improvement of Embodiment 1, such as image 3 As shown, wherein, step 3) is to carry out the following steps by a predetermined number of times:

[0048] 51) Fill the hollow cylinder with a predetermined amount of SAP / SAF;

[0049] 52) filling the spacer in the hollow cylinder;

[0050] 53) Return to step 51).

[0051] The purpose of adding spacers is to form multiple cavities in the hollow cylinder, so that the distribution (SAP / SAF) in the hollow cylinder is relatively uniform. Spacers can be selected from paper balls, plastic film balls, non-woven fabric balls, etc. as required. In order to facilitate mechanized production, it can be filled with quick-drying materials.

[0052] Wherein, the quantity isolated by the spacer can be set as required. The thickness of the spacer should not be too large. The better way is to fill it with lumps, so that when (SAP / SAF) absorbs liquid, it will expand, so that the spacer can be squeezed in the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com