Main grid-free solar cell piece welding device

A technology for welding solar cells and cells, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems that cannot meet the needs of the welding quality and welding efficiency of the battery pack, and achieve improved efficiency, reduced whitening, and guaranteed The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

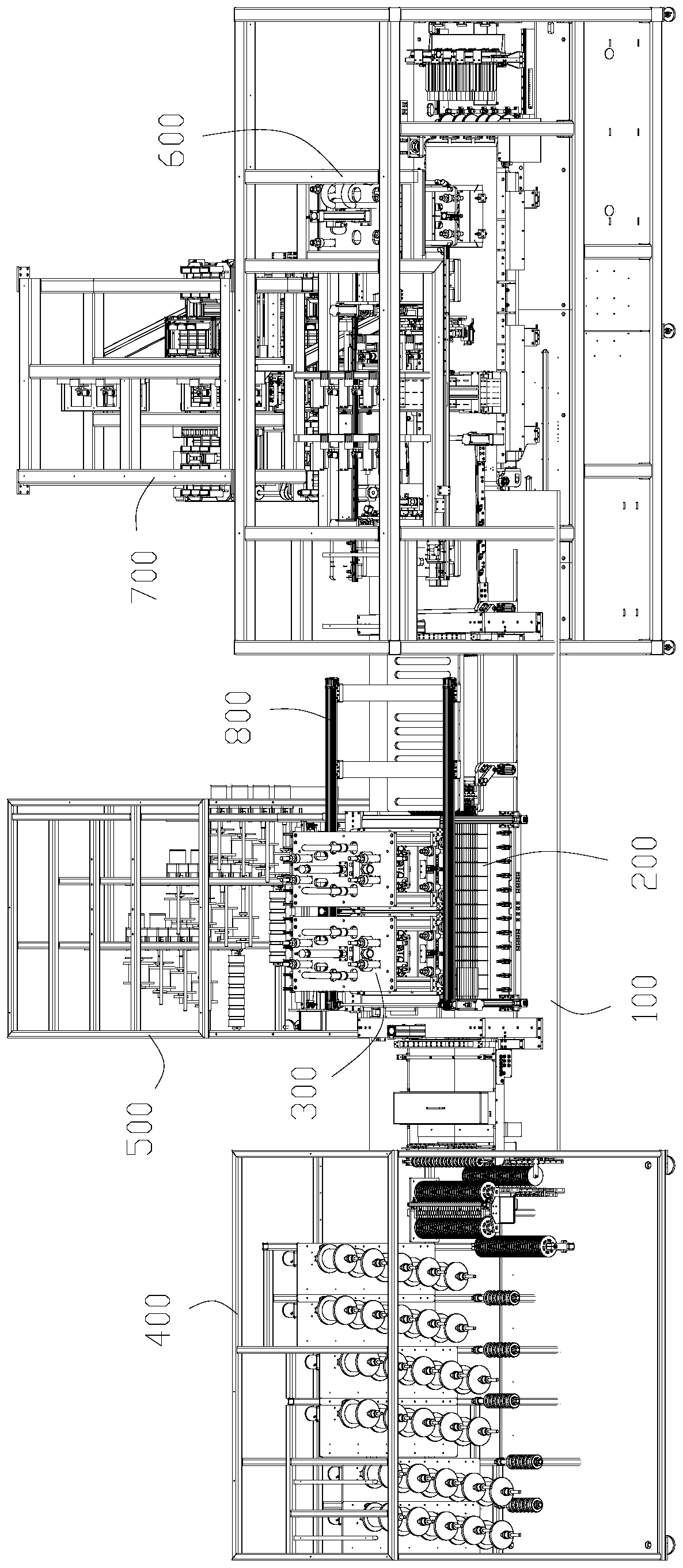

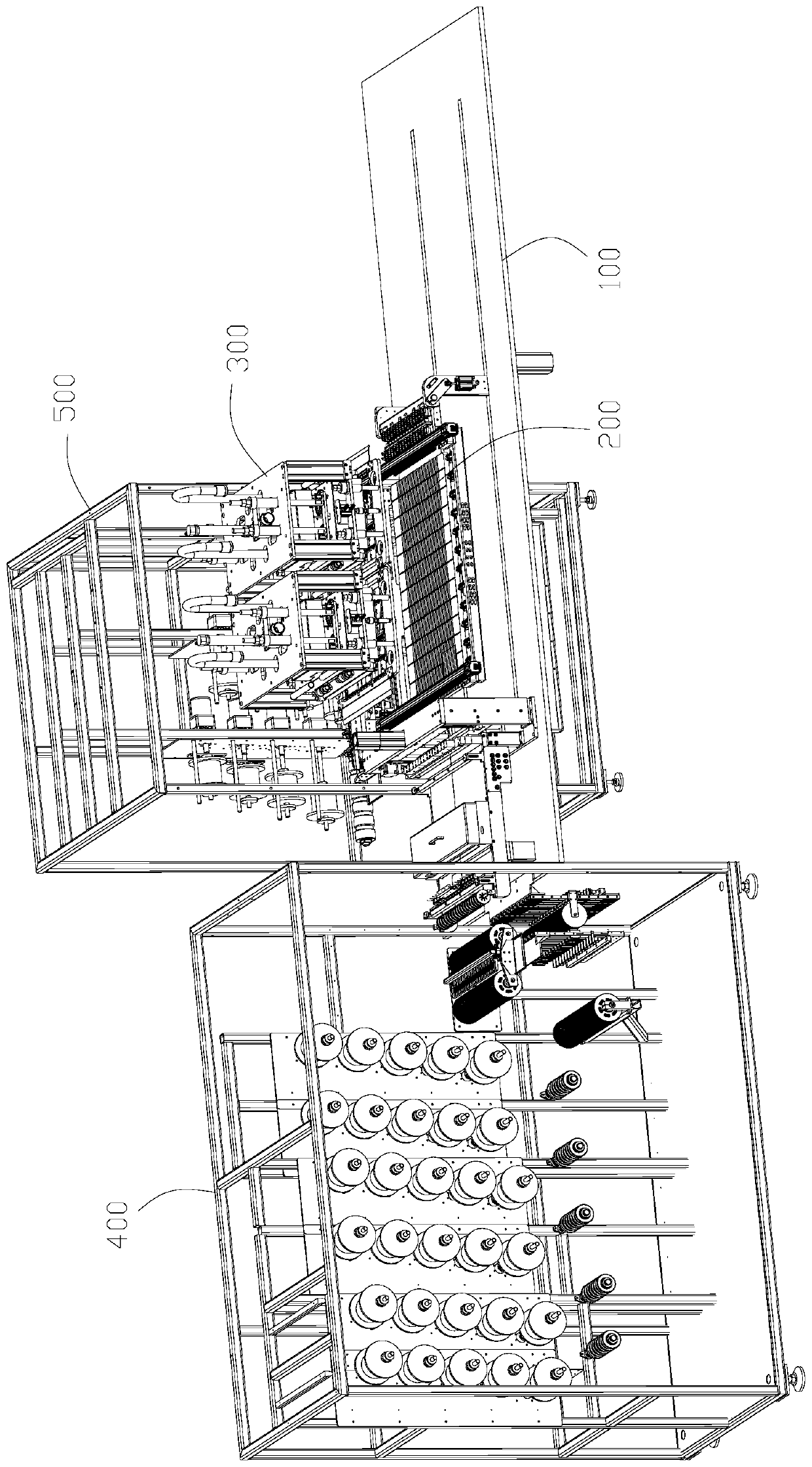

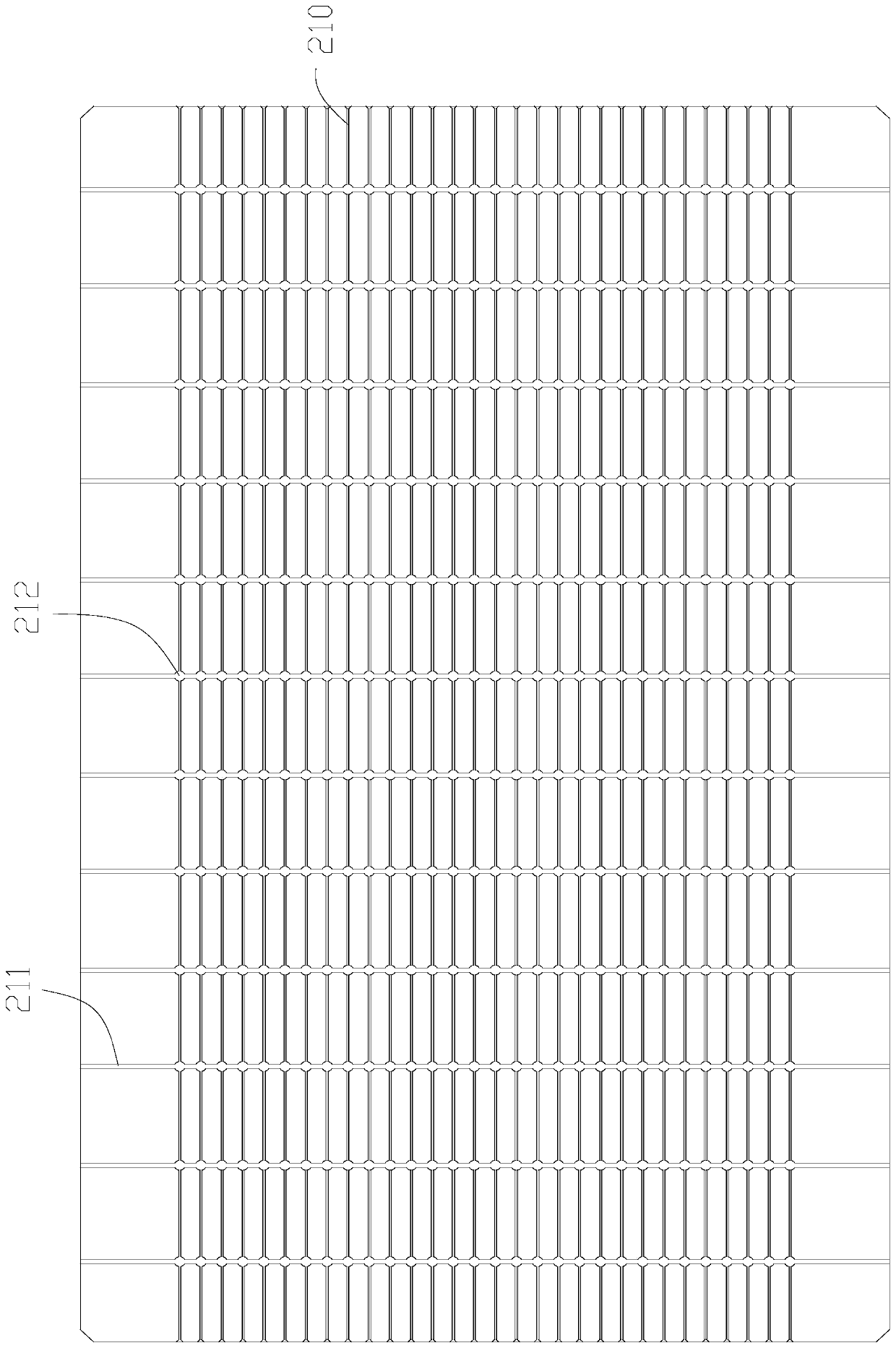

[0067] A busbar-free solar cell sheet welding device, such as figure 1 shown, including:

[0068] Welding mesh welding device, used to weld welding wire into welded mesh;

[0069] Cell welding machine 600, the cell welding machine 600 includes a transmission welding station 610 and a lampshade welding device 620, used to weld the welding mesh and the non-busbar cell into a solar cell plate;

[0070] A battery sheet feeding device 700, the battery sheet feeding device 700 transports the battery sheet to the transfer welding station 610 through the battery sheet conveying device 710;

[0071] The welding net feeding device 800 is used for transporting the welded net welded and formed by the welding net welding device to the busbarless battery slices on the battery slice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com