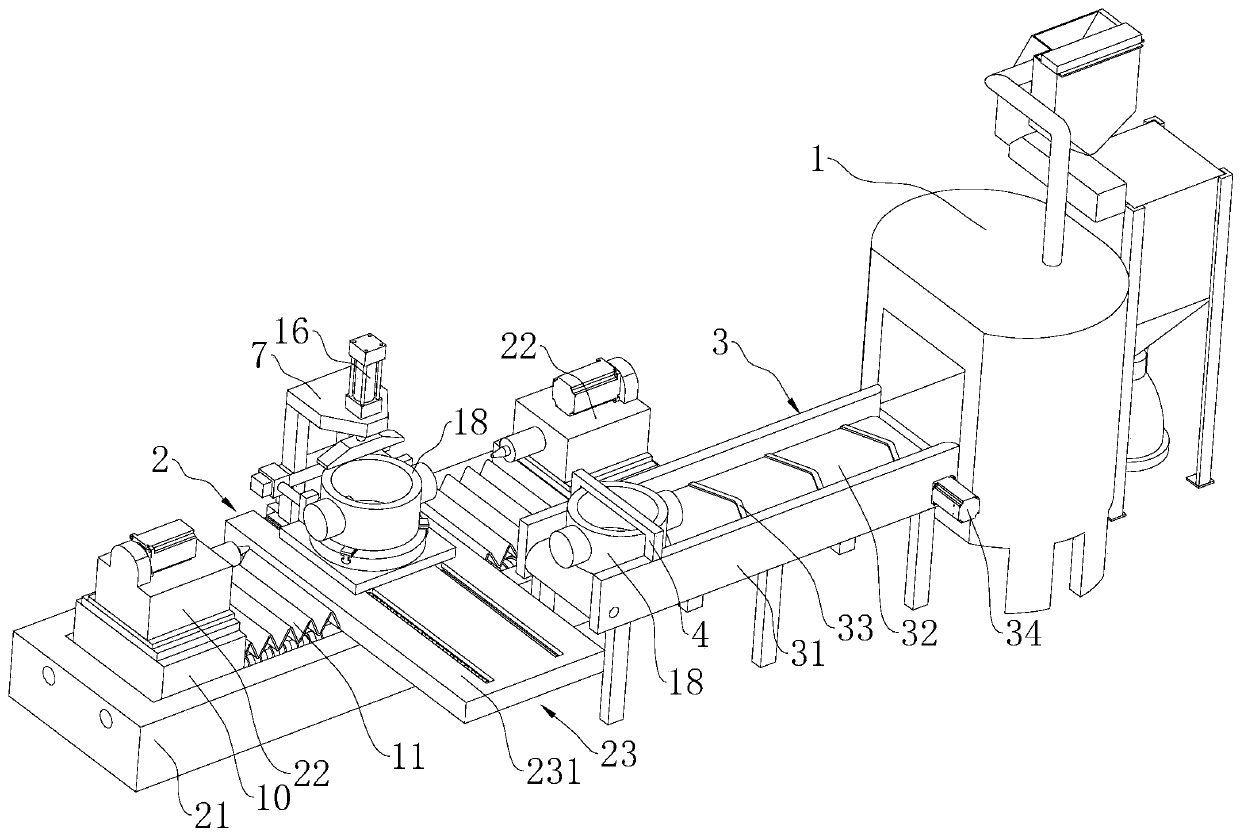

Production device of hinge shafts

A production device and hinge shaft technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high labor intensity and affecting production efficiency, so as to improve drilling efficiency, reduce labor intensity and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

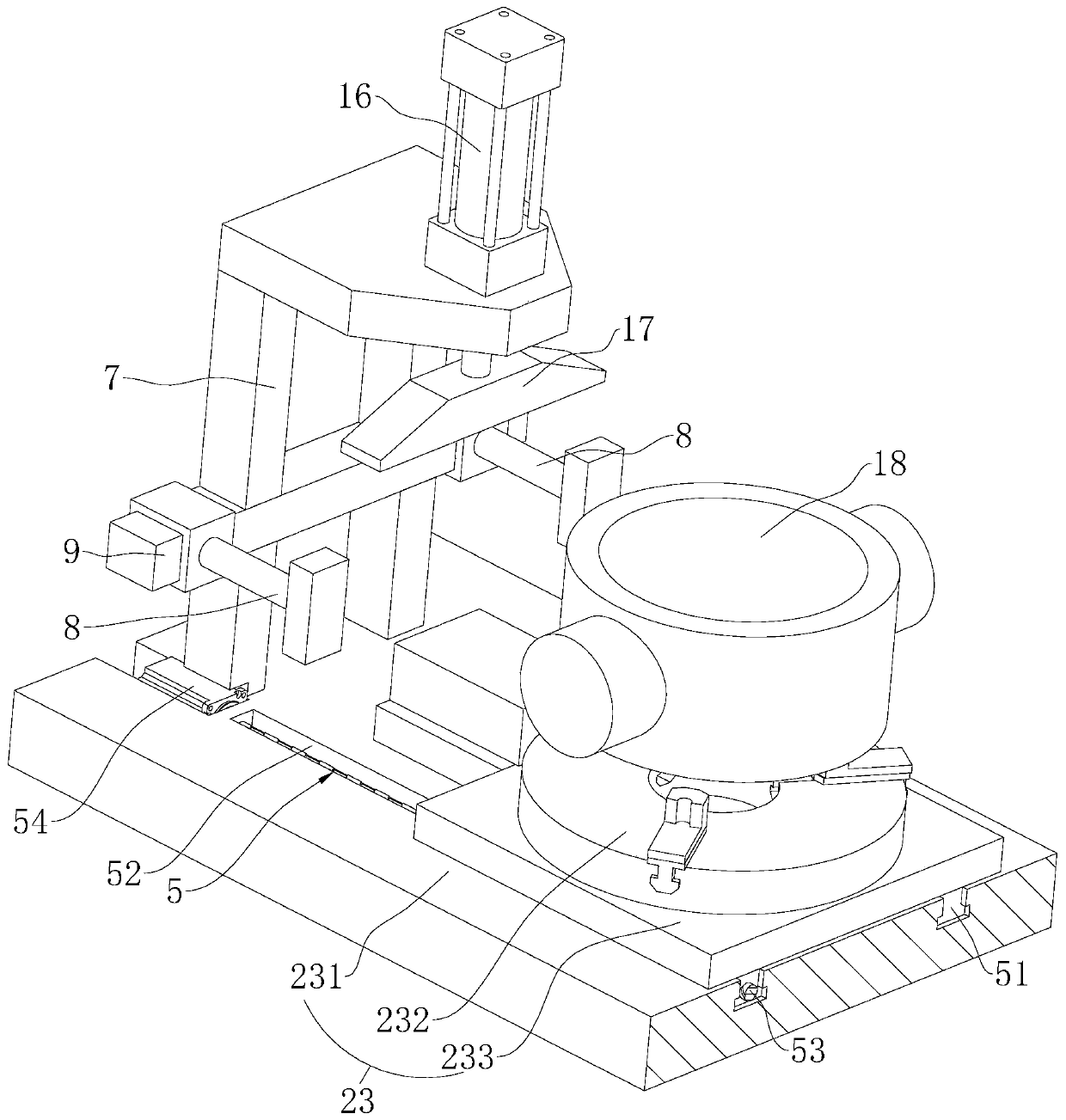

Examples

Embodiment 2

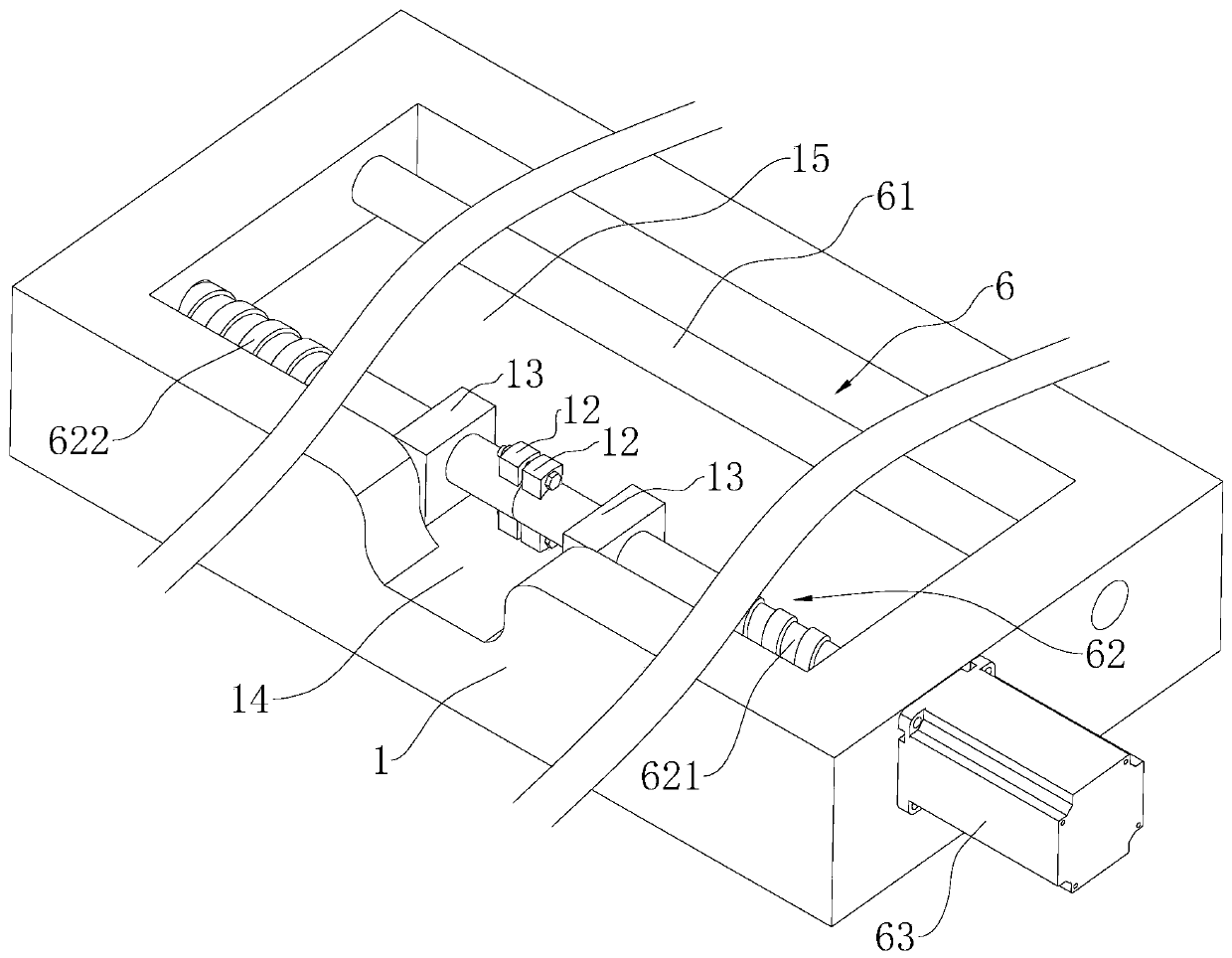

[0048] Embodiment 2: The difference with Embodiment 1 is that, with reference to figure 2 , the above-mentioned threaded rod one 621 and the adjacent end of the threaded rod two 622 are separated, and the outer walls of the threaded rod one 621 and the threaded rod two 622 adjacent ends are respectively provided with two sets of corresponding limit blocks 12, and the two sets of limit blocks 12 is evenly arranged along the threaded rod one 621 / threaded rod two 622 circumferential direction; two sets of limit blocks 12 are provided with corresponding through holes, and the same bolt is inserted in the through holes of the same set of limit blocks 12, and one end of the bolt is connected to the nut The threads are matched to realize the coaxial connection or separation of the first threaded rod 621 and the second threaded rod 622.

[0049] In this embodiment, the chute 15 is located below the mounting seat 231 and two positioning seats 13 are fixed, and one end of the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com