Antirust oil and preparation method thereof

A technology of anti-rust oil and machine oil, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high fastener cost, prolong production cycle, and increased fastener cost, so as to avoid corrosion damage and improve anti-rust ability , the effect of strong adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

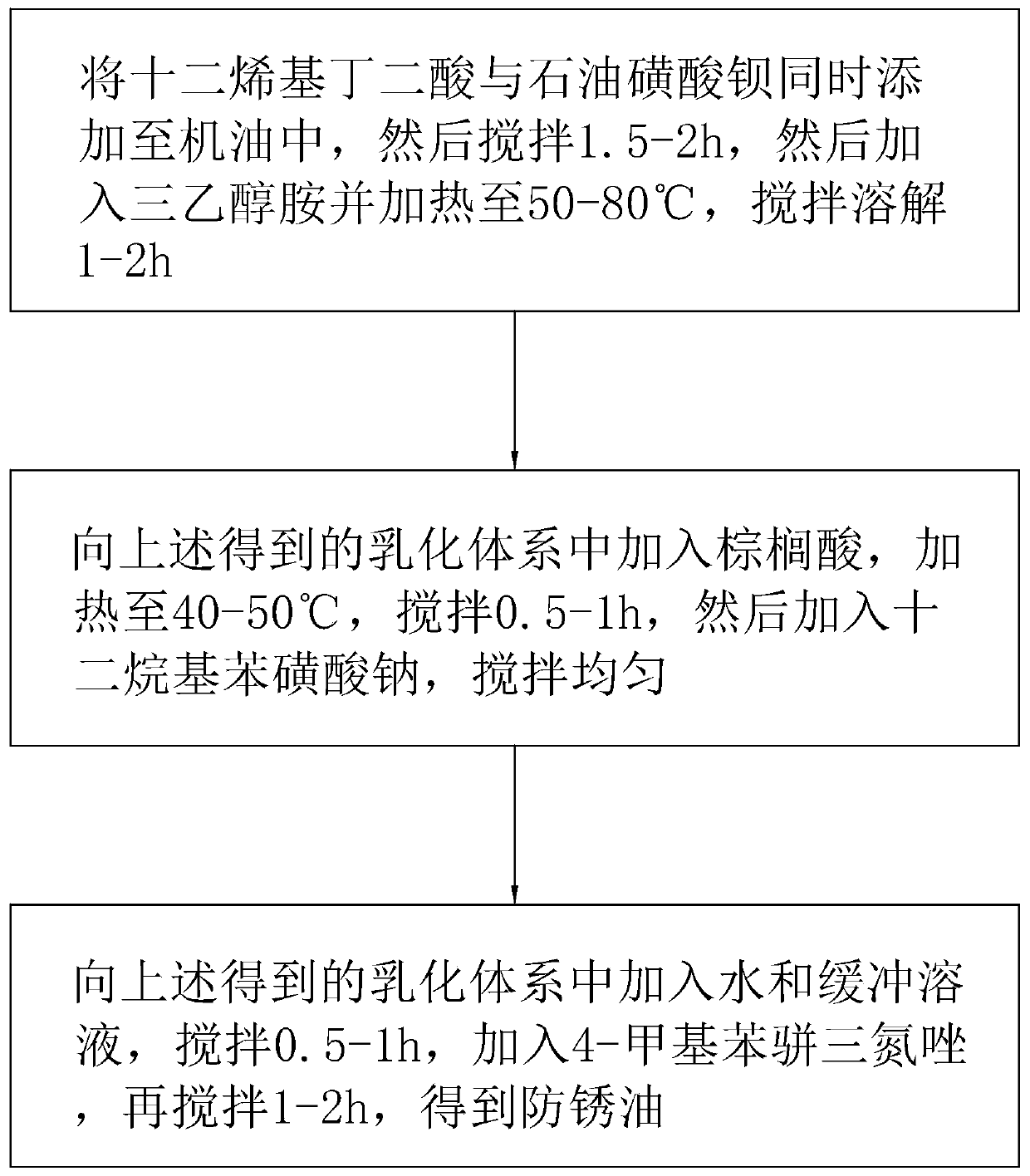

[0045] Embodiment 1: A kind of antirust oil, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0046] (1) Add dodecenylsuccinic acid and barium petroleum sulfonate to the engine oil at the same time, then stir for 2 hours, then add triethanolamine and heat to 50°C, stir and dissolve for 2 hours;

[0047] (2) Add palmitic acid to the emulsification system of step (1), heat to 40° C., stir for 1 h, then add sodium dodecylbenzenesulfonate, and stir evenly;

[0048] (3) Add water and buffer solution to the emulsification system in step (2), stir for 1 hour, add 4-methylbenzotriazole, and stir for another 2 hours to obtain antirust oil.

[0049] Wherein the buffer solution is a mixed solution of sodium carbonate and sodium bicarbonate, and the pH is controlled between 10-11.5.

Embodiment 2-6

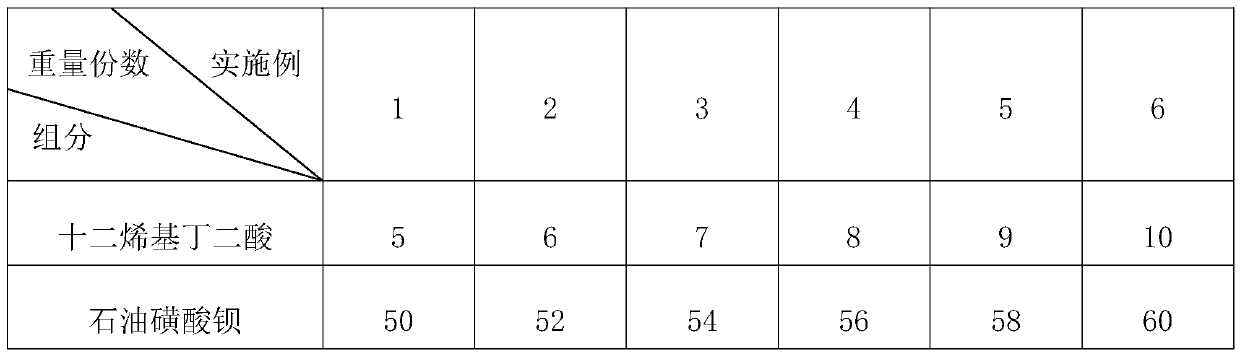

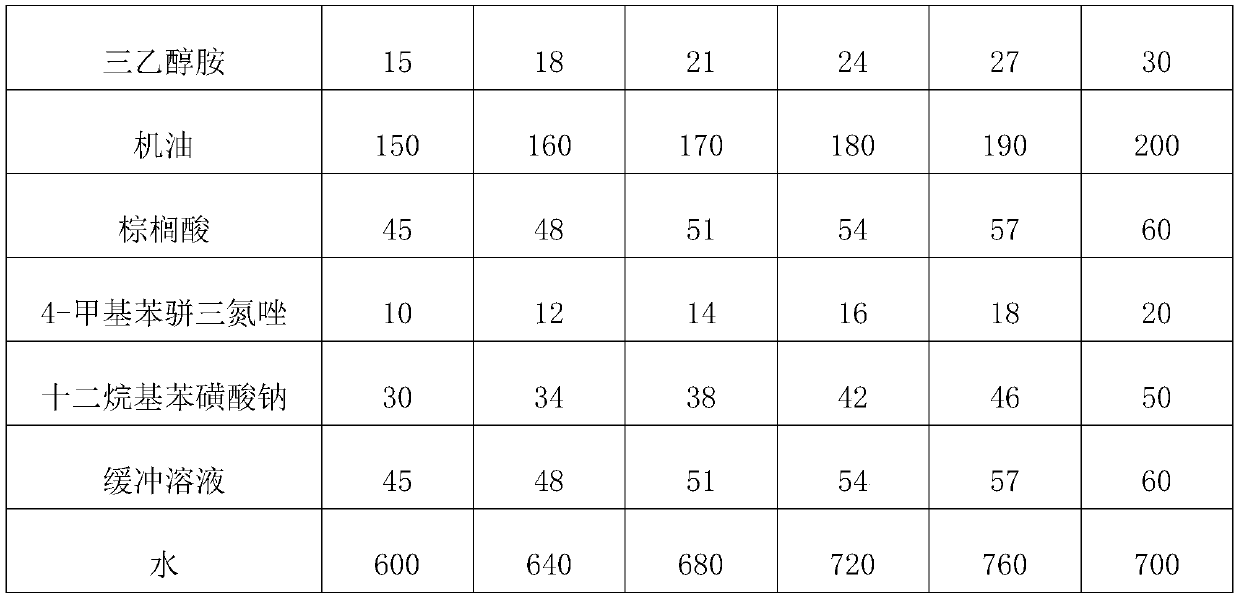

[0050]Embodiment 2-6: a kind of antirust oil, the difference from embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0051] Each component and parts by weight thereof in table 1 embodiment 1-6

[0052]

[0053]

Embodiment 7

[0054] Embodiment 7: a kind of preparation method of antirust oil, the difference with embodiment 1 is, also added 10 parts of antibacterial agents in step (3), and antibacterial agents are obtained by following preparation steps:

[0055] Add 1g carboxymethyl chitosan to 250mL deionized water, stir evenly, add 250mL silver nitrate solution with a concentration of 2mmol / L, stir and heat to 60°C, react for 1h and cool to 25°C, dropwise at a concentration of 1mmol / L L of sodium borohydride solution, stirred and reacted for 0.5h to obtain an antibacterial agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com