Wearproof antibacterial tile

A tile and ceramic technology, applied in the field of ceramic processing, can solve the problems of poor wear resistance of tiles, poor ventilation and lighting, and reduced wear resistance of tiles, so as to reduce water absorption, simplify edging and polishing procedures, and improve smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

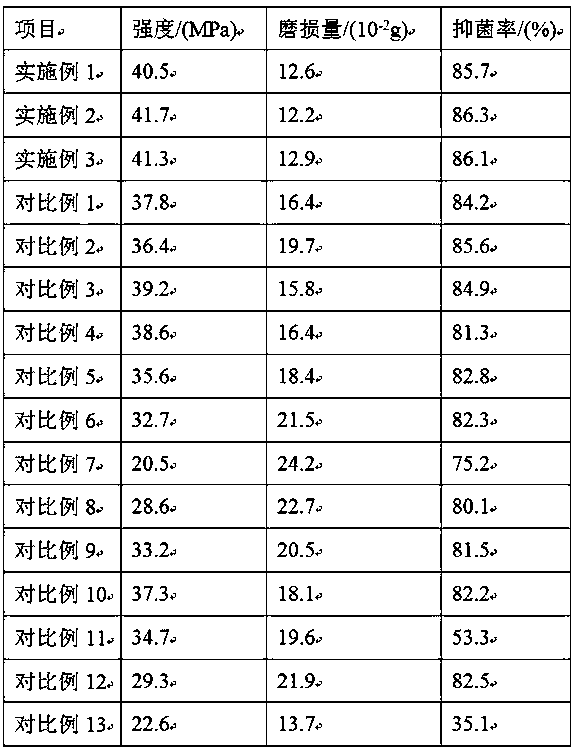

Examples

Embodiment 1

[0023] A wear-resistant and antibacterial tile, made of the following raw materials in parts by weight: dolomite 41, barite 37, ceramic reclaimed material 37, limestone 31, potassium feldspar 31, wollastonite 26, modified serpentine 25, Talc 22, ettringite 13.

[0024] The dolomite has a white color, a Mohs hardness of 3.6-3.9, and a density of 2.9-3.1 g / cm.

[0025] The reclaimed ceramic material is one or a mixture of any of waste ceramics, defective ceramics, and ceramic scraps.

[0026] For the modified serpentine, the serpentine is pulverized to 40-60 μm, heated to 450 °C at a rate of 2 °C / min, kept for 40 minutes, and then heated to 1100-1180 °C at a rate of 1.4 °C / min ℃, increase the porosity of serpentine, add a sodium silicate solution with a concentration of 70 mg / L equal to that of serpentine, mix well, and keep warm for 30 minutes to make the sodium silicate solution fill the pores, which is beneficial to serpentine and silicic acid The sodium is closely combined...

Embodiment 2

[0038] A wear-resistant and antibacterial tile, made of the following raw materials in parts by weight: dolomite 42, barite 38, ceramic reclaimed material 38, limestone 32, potassium feldspar 32, wollastonite 27, modified serpentine 26, Talc 23, ettringite 14.

[0039] The dolomite has a white color, a Mohs hardness of 3.6-3.9, and a density of 2.9-3.1 g / cm.

[0040] The reclaimed ceramic material is one or a mixture of any of waste ceramics, defective ceramics, and ceramic scraps.

[0041] The modified serpentine is crushed to 50 μm, heated to 480°C at a rate of 2.5°C / min, kept for 50 minutes, and then heated to 1140°C at a rate of 1.6°C / min to increase the To improve the porosity of striatum, add a sodium silicate solution with a concentration of 80 mg / L equal to that of serpentine, mix well, and keep warm for 40 minutes to make the sodium silicate solution fill the pores, which is conducive to the close combination of serpentine and sodium silicate. Reduce the water absor...

Embodiment 3

[0053] A wear-resistant and antibacterial tile, made of the following raw materials in parts by weight: dolomite 43, barite 39, ceramic reclaimed material 39, limestone 33, potassium feldspar 33, wollastonite 28, modified serpentine 27, Talc 24, ettringite 15.

[0054] The dolomite has a white color, a Mohs hardness of 3.6-3.9, and a density of 2.9-3.1 g / cm.

[0055] The reclaimed ceramic material is one or a mixture of any of waste ceramics, defective ceramics, and ceramic scraps.

[0056] The modified serpentine is crushed to 60 μm, heated to 500°C at a rate of 3°C / min, kept at a temperature of 60 minutes, and then heated to 1180°C at a rate of 1.8°C / min to increase the To improve the porosity of striatum, add a sodium silicate solution with a concentration of 90 mg / L equal to that of serpentine, mix well, and keep warm for 50 minutes to make the sodium silicate solution fill the pores, which is conducive to the close combination of serpentine and sodium silicate. Reduce t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com