Integrated control system of piston variable pump

A technology of integrated control system and integrated control components, applied in the direction of pump control, variable capacity pump components, pumps, etc., can solve the problems of pressure cut-off control safety protection failure and rise, so as to improve the safety of use and prevent pressure surges drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

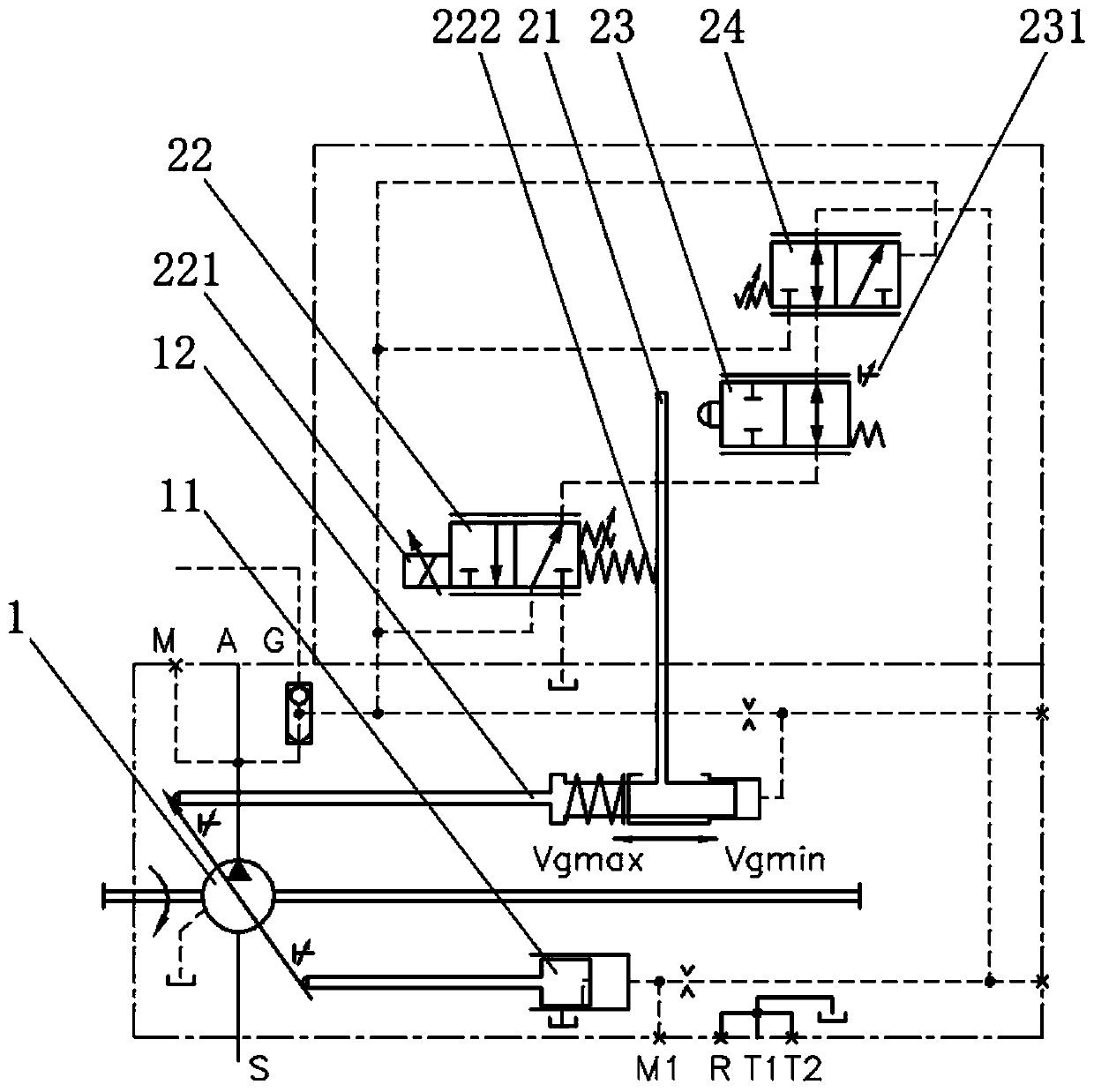

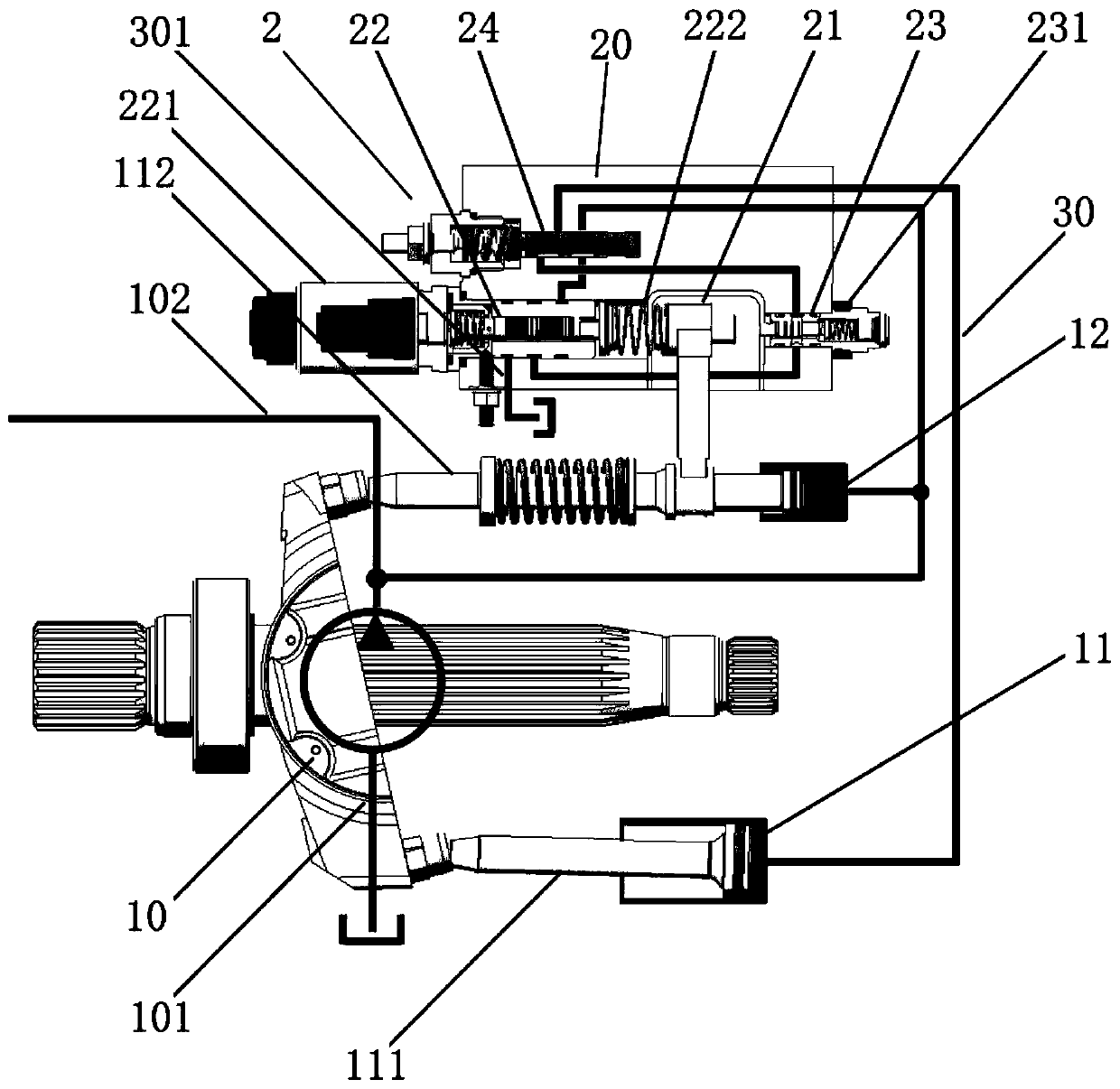

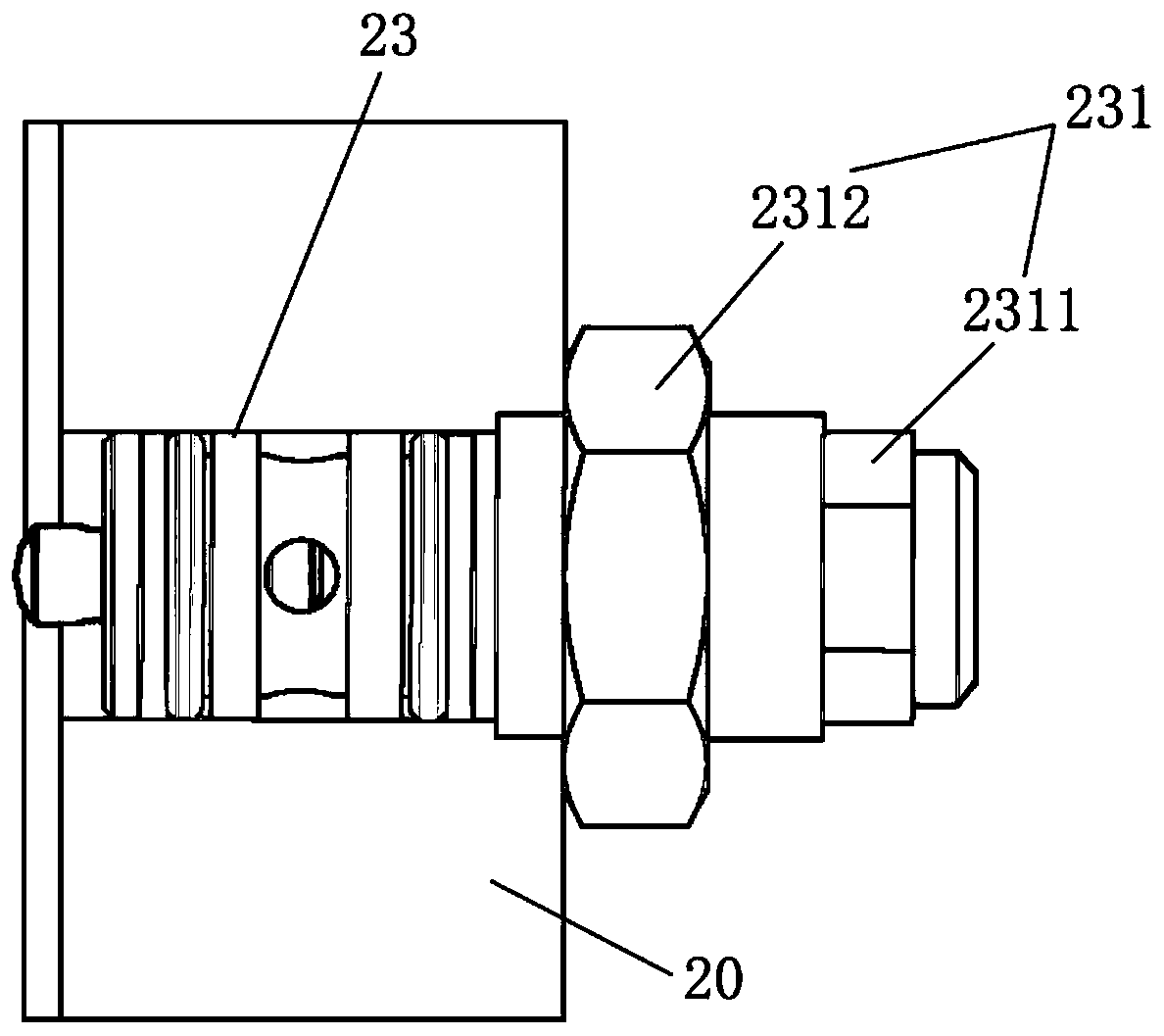

[0023] Such as figure 1 with figure 2 As shown, an integrated control system for a variable displacement plunger pump of the present invention is installed in combination with a variable displacement plunger pump 1. The variable displacement plunger pump 1 includes a swash plate 10 installed on the variable displacement piston pump 1 Inside, its inclination angle determines the displacement of the variable displacement plunger pump 1 , and the variable displacement plunger pump 1 has a plunger pump oil inlet 101 and a plunger pump oil outlet 102 . The integrated control system of the plunger variable displacement pump includes a large connecting rod 111 , a small connecting rod 112 , a lower variable cylinder 11 , an upper variable cylinder 12 , an integrated control assembly 2 and a control oil circuit 30 . The large connecting rod 111 and the small connecting rod 112 are respectively hinged to two ends of the swash plate 10 . The large connecting rod 111 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com