Rapid drying device for pulping machine for chemical fabric processing

A technology of rapid drying and sizing machine, which is applied in the direction of heating device, drying, drying machine, etc. It can solve the problems of water vapor discharge of non-wet chemical fiber cloth, insufficient drying of chemical fiber cloth, and affecting the processing effect, etc., and achieves the goal of using Safe and convenient, increase the temperature, improve the effect of dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

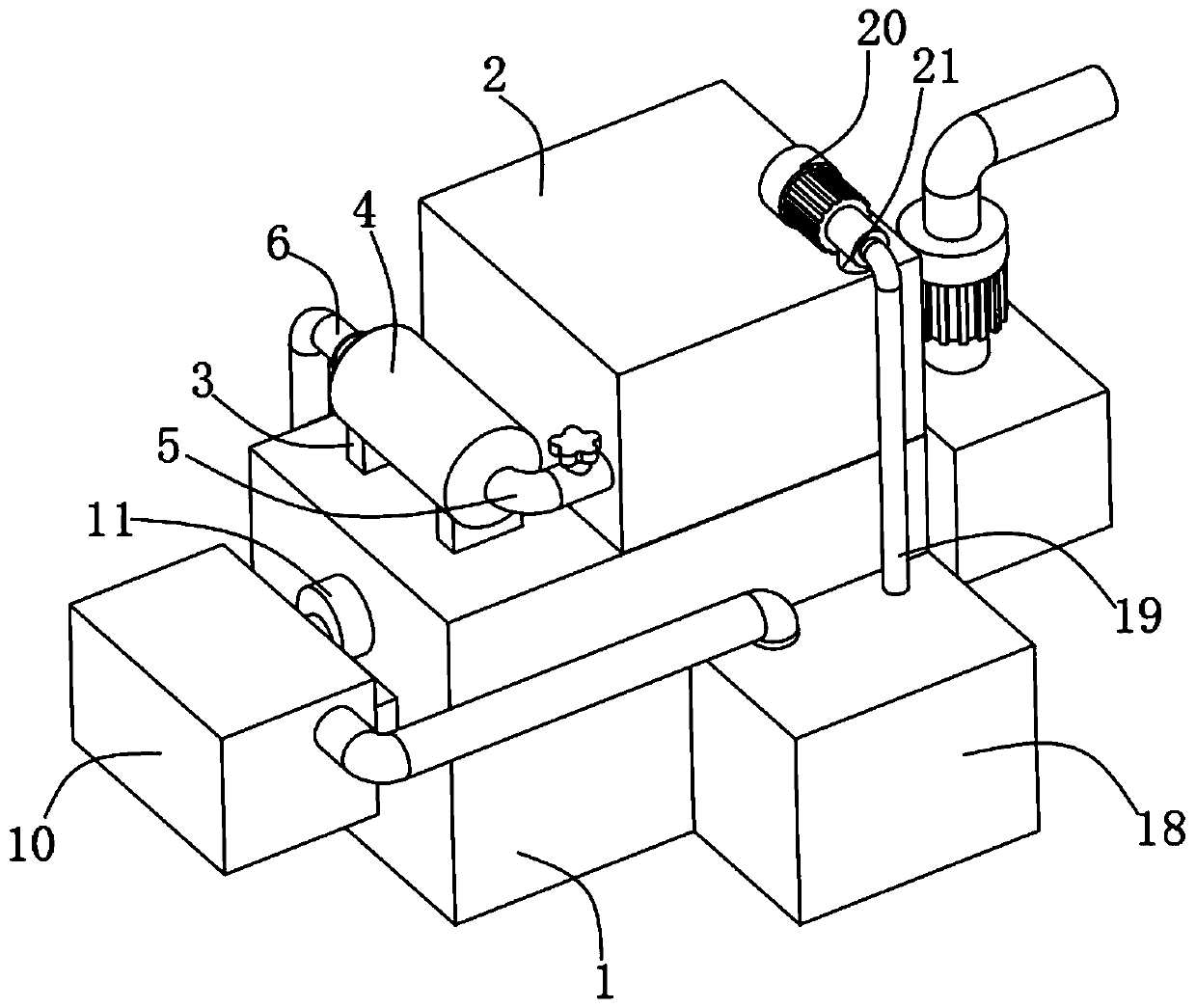

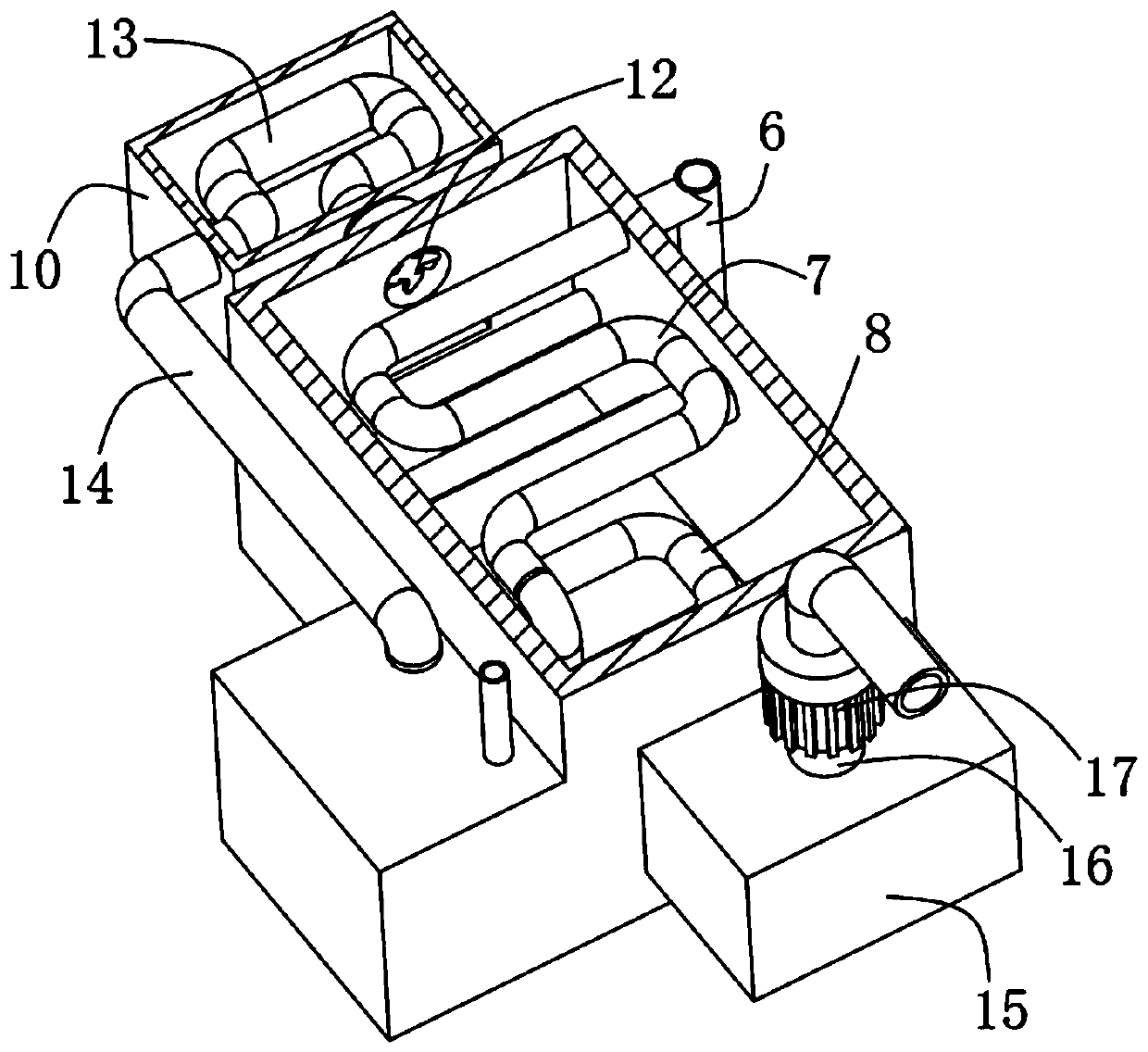

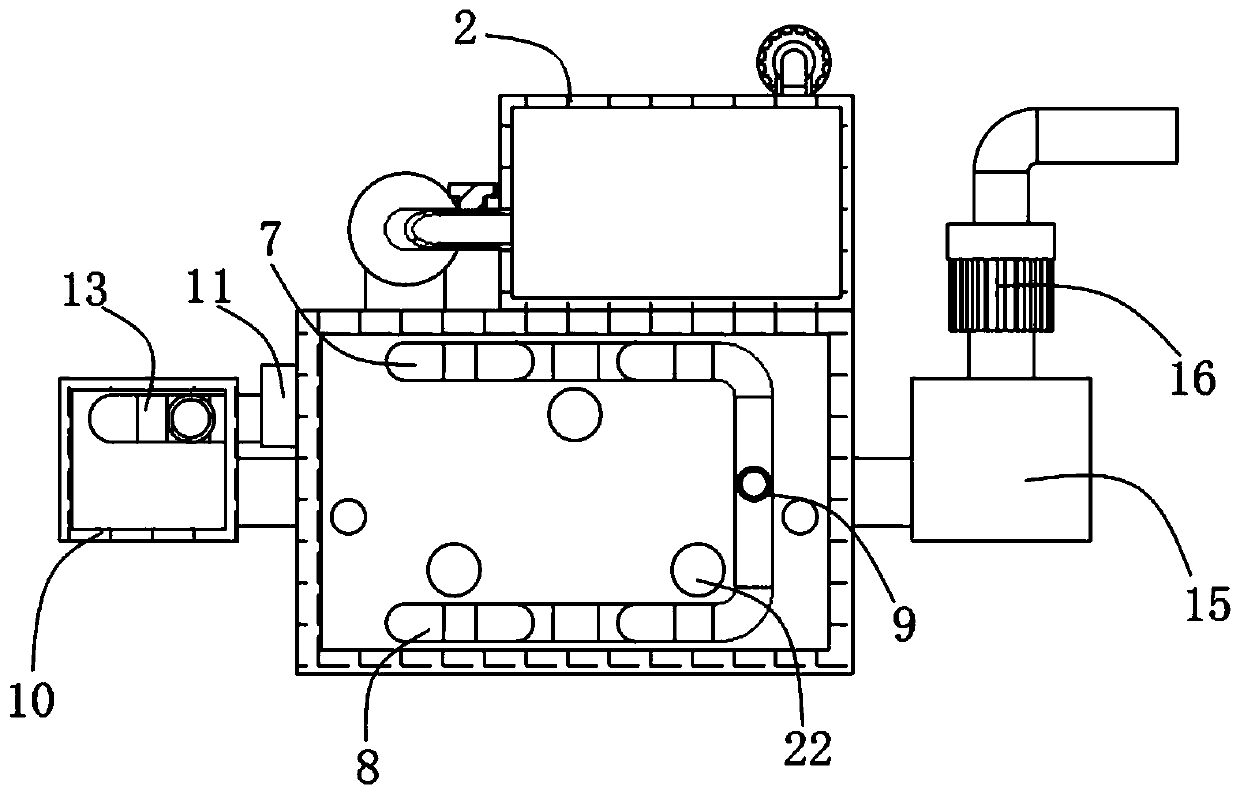

[0023] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a fast drying device for a sizing machine for chemical fiber cloth processing, including a drying box 1. In order to facilitate the guidance of chemical fiber cloth, the inside of the drying box 1 is rotatably connected with a drum 22, and the drum 22 There are three in total, and the three rollers 22 are staggeredly distributed inside the drying box 1, the top side of the drying box 1 is fixedly connected to the water tank 2, and the top of the drying box 1 is fixedly connected to the side position of the water tank 2 with a fixed seat 3. The top of the fixing seat 3 is fixedly connected with the steam generator 4, one end of the steam generator 4 is fixedly connected with the water outlet pipe 5, and the other end of the water outlet pipe 5 is fixedly connected with one end of the water tank 2, and the steam generator 4 is fixedly connected with one end away from the water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com