Coupling fiber manufacturing method and assembly clamp

A technology for assembling a fixture and a manufacturing method, which is applied to the coupling of optical waveguides, light guides, optics, etc., can solve the problems of easily burning optical fibers, reducing power, affecting coupling efficiency, etc., so as to improve coupling efficiency, ensure mechanical tension, and be difficult to absorb heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

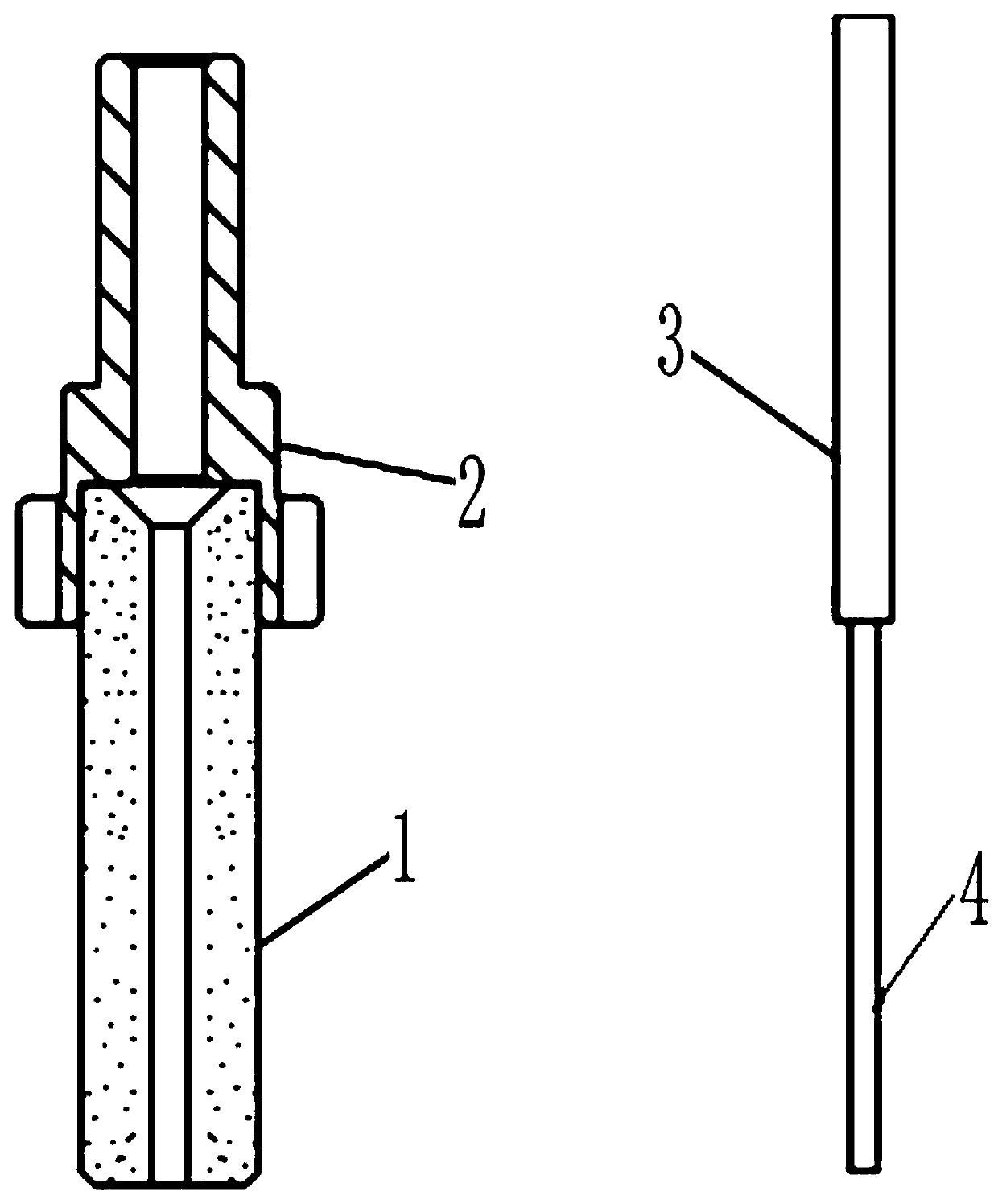

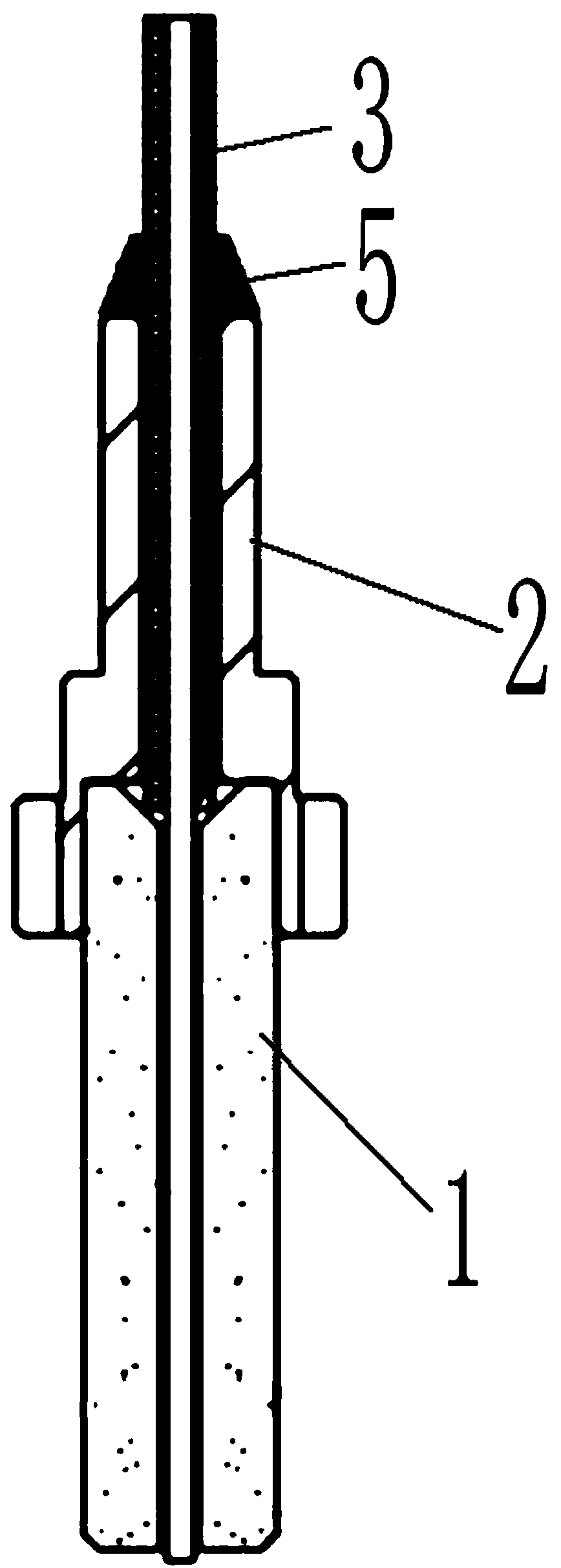

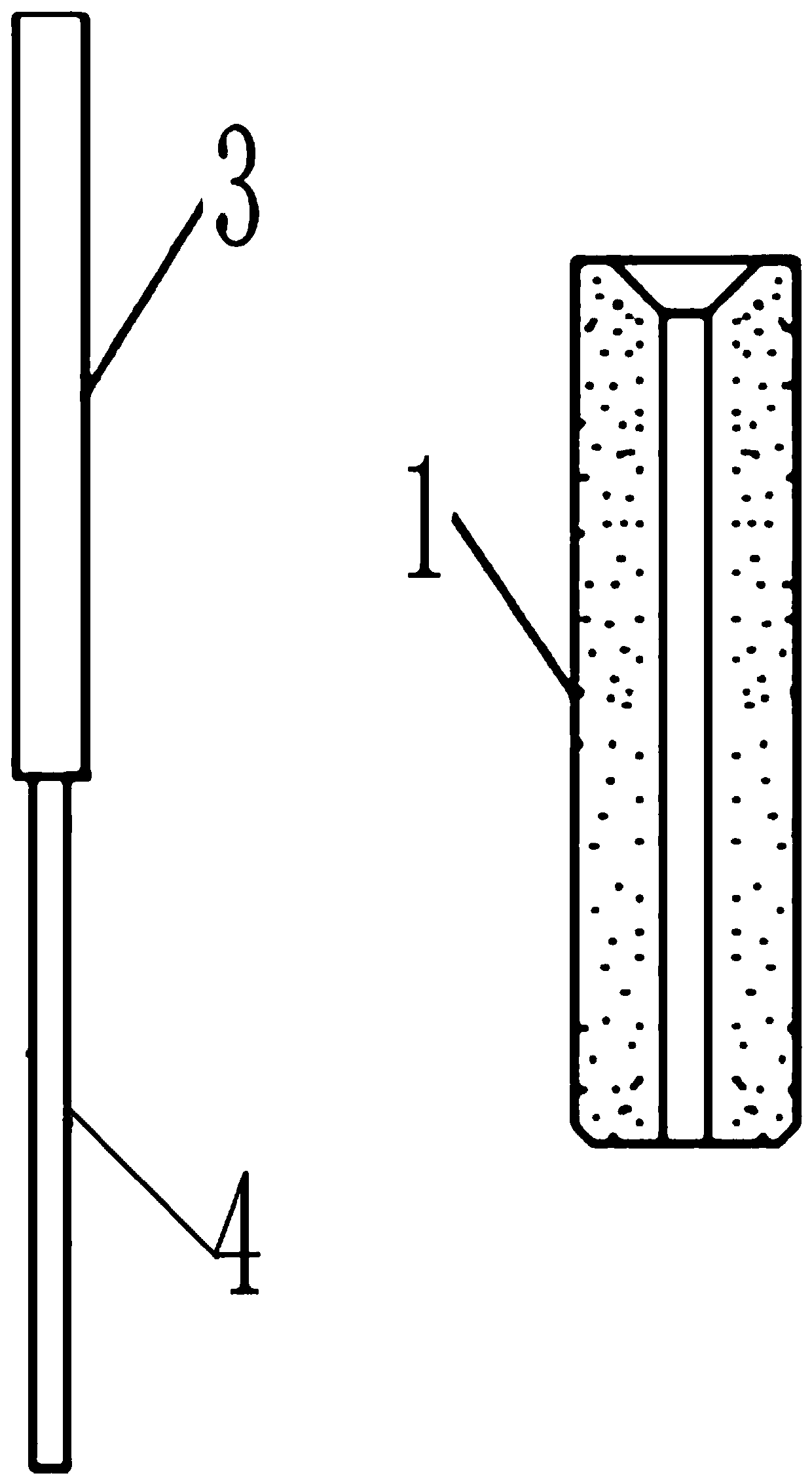

[0051] A step of grinding the bare end 4 after step a) is also included. Grinding the exposed end 4 can ensure the smoothness of its surface, which is beneficial to improve its transmission rate of optical signals.

Embodiment 2

[0053] It also includes the step of inspecting the coating on the surface of the exposed end 4 after step a). Before curing the optical fiber 3 and the ferrule holder 2, it is checked whether the coating of the optical fiber bare end 4 is damaged, so as to ensure the quality of the coupled optical fiber.

Embodiment 3

[0055] The glue-coated area in step b) is 1 / 2 area of the whole exposed end 4 upward from the center point of the exposed end 4 . Setting 1 / 2 area for glue coating can satisfy the fixing firmness of the bare fiber end 4 and the ferrule seat 2, so that it can meet the requirements of mechanical tension, and can prevent overflow caused by excessive glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com