Explosion-proof motor base adopting ejection line structure

A motor base, explosion-proof technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of severe vibration, affecting the service life of the motor, working efficiency, and large temperature rise, so as to reduce the vibration speed, Improve the effect of ventilation and heat dissipation, reduce the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

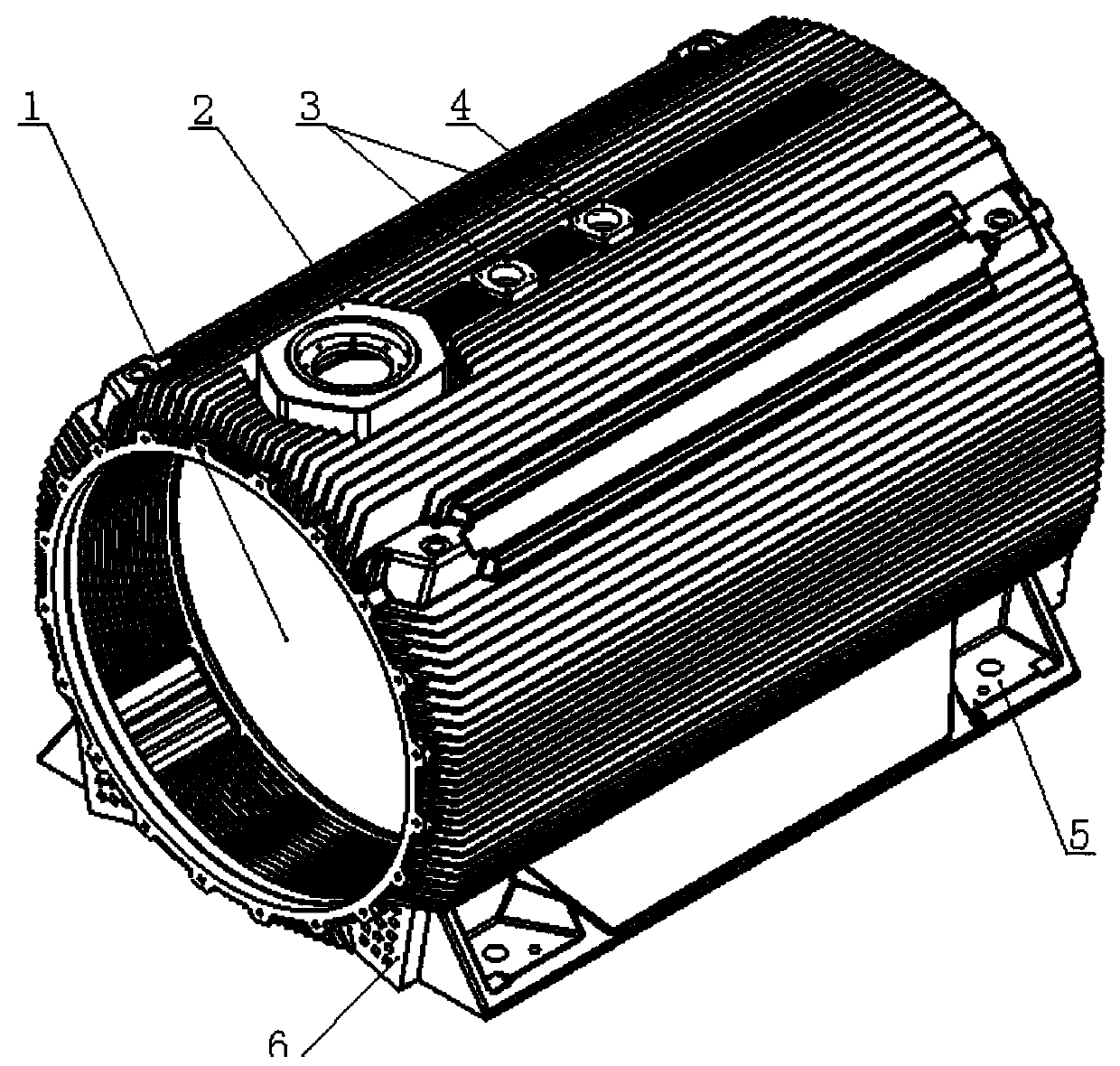

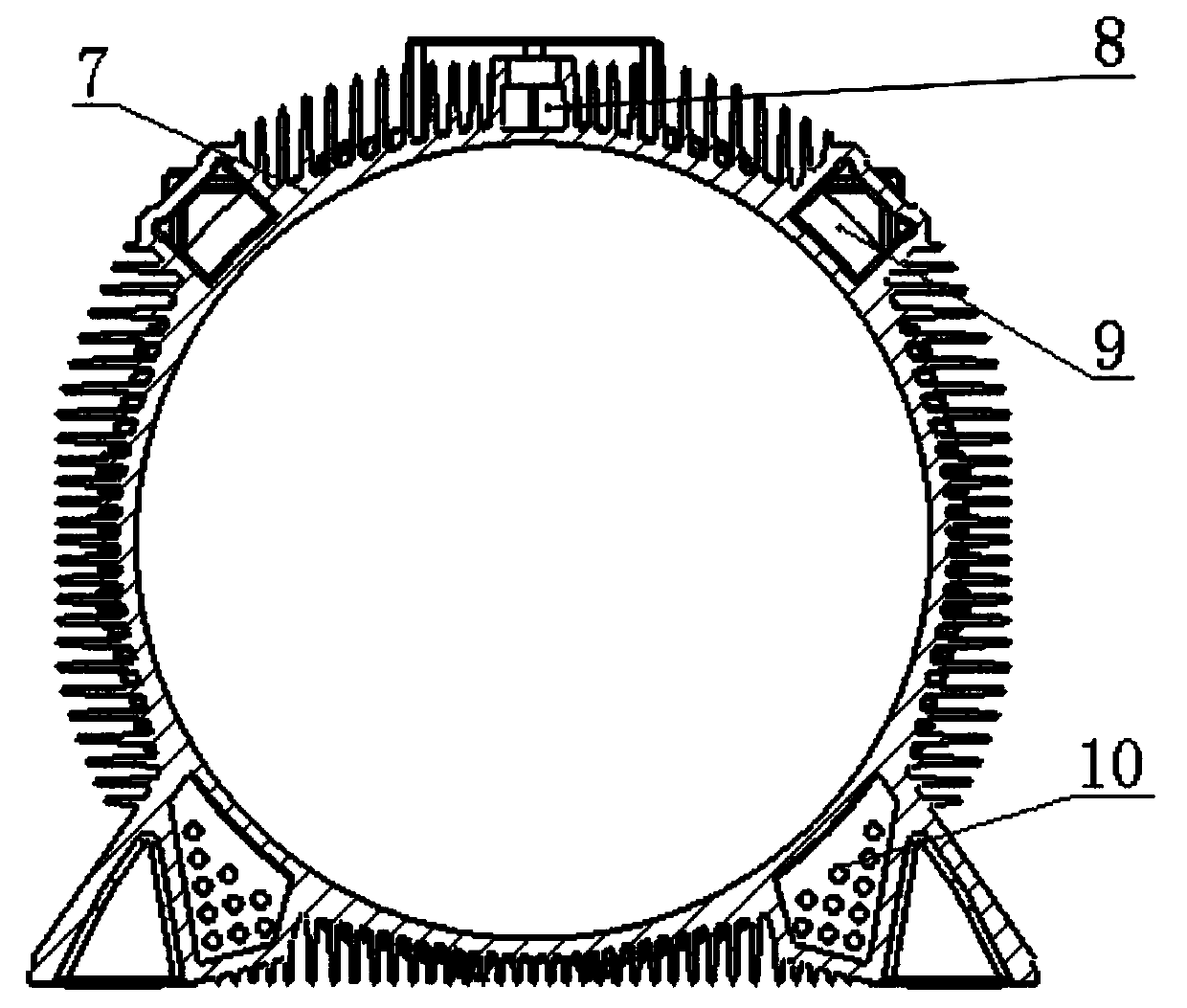

[0032] like Figure 1-5 , the present invention is a flameproof motor base with a top-out line structure, its external structure mainly includes a base cylinder 1, a main junction box seat 2, an auxiliary junction box seat 3, an external heat sink 4, and feet 5, 2 Box air duct 6.

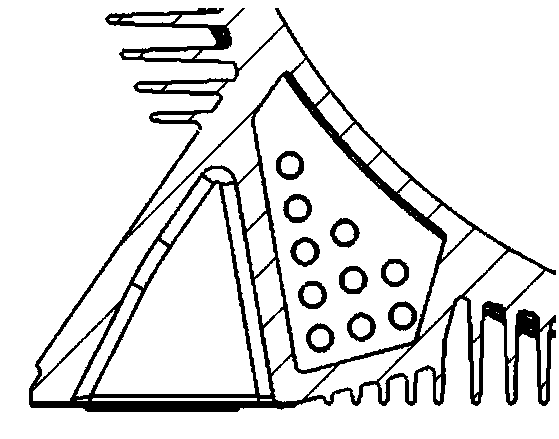

[0033] There are five ventilation ducts distributed inside the machine base, and the connection between the air ducts and the machine base tube adopts a variable thickness structure 7, which can effectively reduce stress concentration and effectively improve the structural strength and rigidity of the machine base. The air ducts are: 1 top air duct 8, 2 upper side air ducts 9, 2 bottom box air ducts 10, the end plate of the bottom box air duct is drilled, and several ventilation pipes 11 are used to improve heat exchange efficiency , both ends are distributed with annular cooling fins 12, and sand cleaning process holes 13 are opened on the base barrel.

[0034] The whole machine base is molded by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com