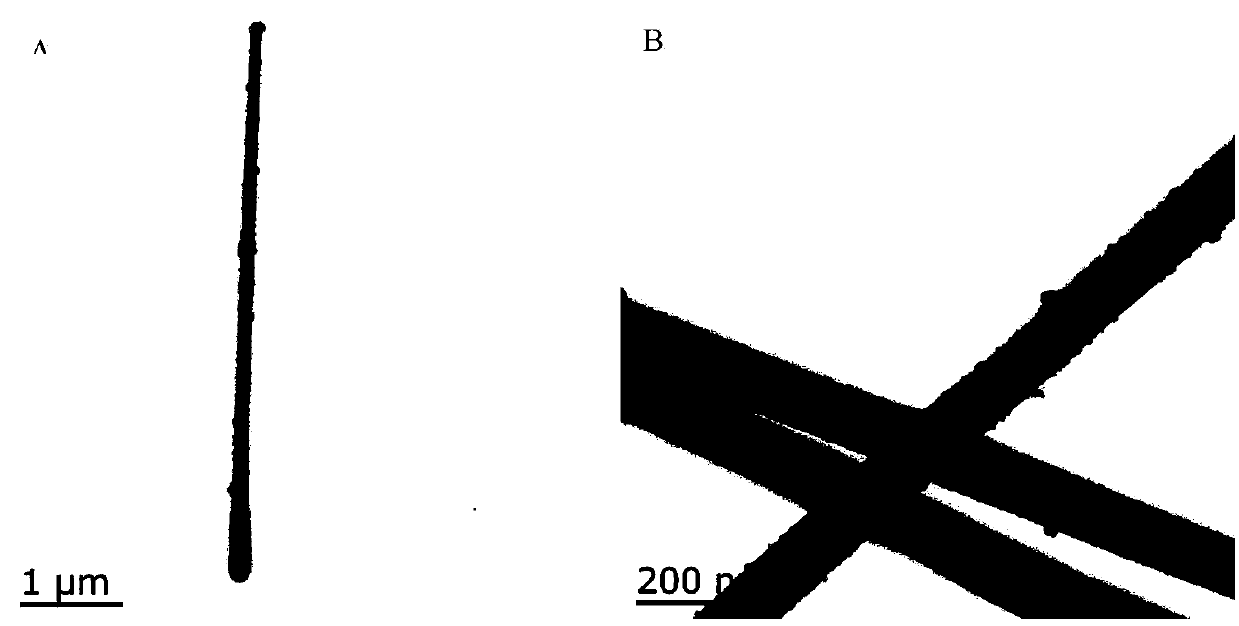

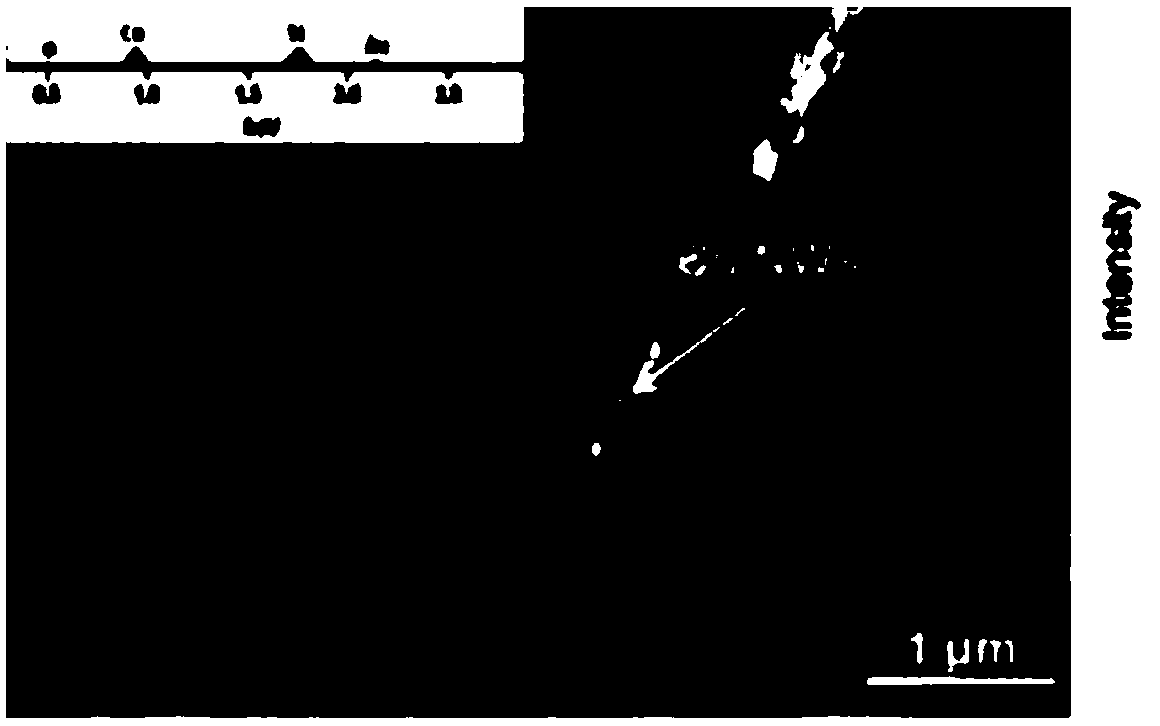

Method for preparing low-sensitivity copper azide by CNTs and copper nano-wires

A technology of copper nanowires and copper nitride, which is applied in the field of preparation of micro-nano energetic materials, can solve problems such as high sensitivity, and achieve the effects of improving reaction efficiency, simple reaction device and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Use a volumetric flask to prepare 200 mL of NaOH solution with a concentration of 15 mol / mL, add it to a 500 mL three-necked flask after cooling, and then add Cu(NO 3 ) 2Solution (10mL, 0.1mol / L), 1.5mL of EDA and hydrazine hydrate (0.25mL, 35wt%) solution, mixed thoroughly; then the three-necked flask was placed in a water bath, heated to 80 ° C, and the reaction time was 1h; After the reaction, the three-neck flask was taken out and cooled to room temperature; the product was centrifuged, washed and collected several times by centrifugation-redispersion with deionized water. Store the resulting copper nanowires in absolute ethanol for later use. Copper nanowires were formulated into 5 mg / mL absolute ethanol mother liquor, which was subjected to ultrasonic treatment for 30 minutes for later use, and single-walled carbon nanotubes were ultrasonically treated in SDS solution for 30 minutes to obtain a uniform dispersion with a solution concentration of 0.4 mg / mL; The a...

Embodiment 2

[0046] Use a volumetric flask to prepare 200 mL of NaOH solution with a concentration of 15 mol / mL, add it to a 500 mL three-necked flask after cooling, and then add Cu(NO 3 ) 2 solution (10mL, 0.1mol / L), 1.8mL of EDA and hydrazine hydrate (0.25mL, 35wt%) solution, mix thoroughly; then place the three-neck flask in a water bath, heat to 85°C, and the reaction time is 1.5h; After the reaction was finished, the three-neck flask was taken out and cooled to room temperature; the product was subjected to centrifugation, and washed and collected several times with deionized water by centrifugation-redispersion. Store the resulting copper nanowires in absolute ethanol for later use. Copper nanowires were formulated into 5 mg / mL absolute ethanol mother liquor, and ultrasonically treated for 20 minutes for later use. Single-walled carbon nanotubes were ultrasonically treated in SDS solution for 20 minutes to obtain a uniform dispersion with a solution concentration of 0.4 mg / mL; The ...

Embodiment 3

[0048] Use a volumetric flask to prepare 200 mL of NaOH solution with a concentration of 15 mol / mL, add it to a 500 mL three-necked flask after cooling, and then add Cu(NO 3 ) 2 solution (10mL, 0.1mol / L), 3.0mL of EDA and hydrazine hydrate (0.25mL, 35wt%) solution, mix thoroughly; then place the three-neck flask in a water bath, heat to 85°C, and the reaction time is 2.0h; After the reaction was finished, the three-neck flask was taken out and cooled to room temperature; the product was subjected to centrifugation, and washed and collected several times with deionized water by centrifugation-redispersion. Store the resulting copper nanowires in absolute ethanol for later use. Copper nanowires were formulated into 5 mg / mL absolute ethanol mother liquor, and ultrasonically treated for 20 minutes for later use. Single-walled carbon nanotubes were ultrasonically treated in SDS solution for 20 minutes to obtain a uniform dispersion with a solution concentration of 0.4 mg / mL; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com