Preparation method of PET protective film with high toughness and impact resistance

An impact-resistant and protective film technology, applied in the field of preparation of high-toughness and impact-resistant PET protective film, can solve the problems of poor toughness, poor impact resistance, shortened product service life, limited application scope of PET protective film, etc. Wear resistance, low production cost, low haze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

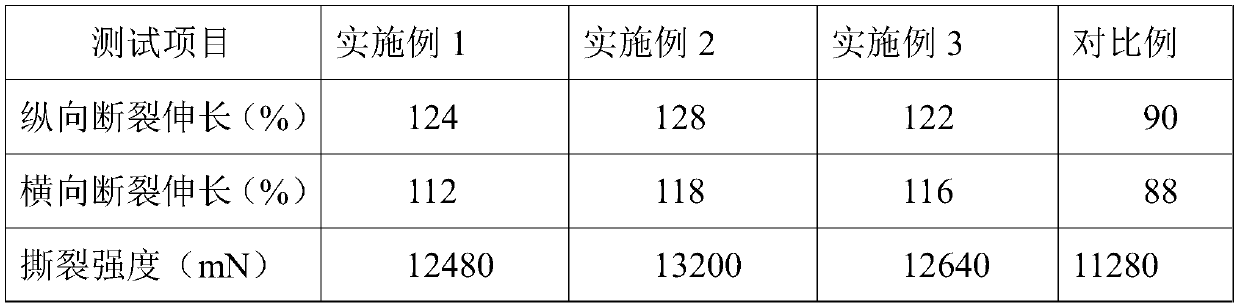

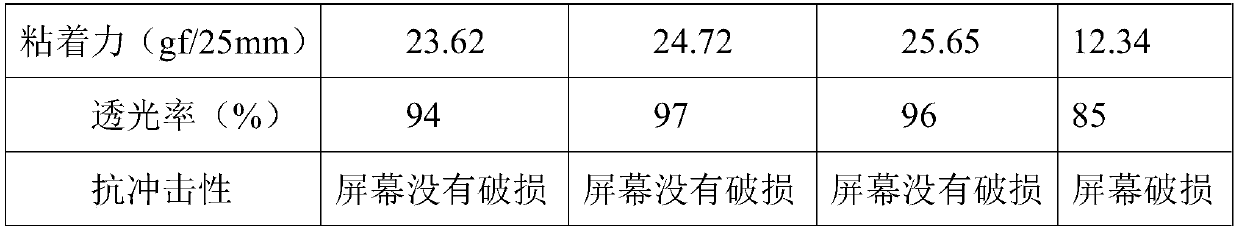

Examples

Embodiment 1

[0026] The invention provides a technical solution: a preparation method of a high-toughness and impact-resistant PET protective film, comprising the following specific steps:

[0027] S1: Select raw materials: including PET substrate layer, polylactic acid composite layer and PET release layer, the PET substrate layer is composed of the following raw materials in parts by weight: 80 parts of PET particles, 2 parts of nano-zirconia, terminal 3 parts of hydroxyl hyperbranched polyester hydroxyl, 1 part of smooth degassing agent and 1 part of leveling agent; the polylactic acid composite layer is composed of the following raw materials in parts by weight: 40 parts of polylactic acid, 9 parts of toughened particles, plasticizer 4 parts of antioxidants and 3 parts of antioxidants.

[0028] S2: Preparation of the PET base material layer: The raw materials of the PET base material layer were mixed evenly in parts by weight, and extruded through an extruder. The extrusion temperature...

Embodiment 2

[0033] The invention provides a technical solution: a preparation method of a high-toughness and impact-resistant PET protective film, comprising the following specific steps:

[0034] S1: Select raw materials: including PET substrate layer, polylactic acid composite layer and PET release layer, the PET substrate layer is composed of the following raw materials in parts by weight: 85 parts of PET particles, 3.5 parts of nano-zirconia, terminal 5 parts of hydroxyl hyperbranched polyester hydroxyl, 1.5 parts of smooth degassing agent and 1.5 parts of leveling agent; the polylactic acid composite layer is composed of the following raw materials in parts by weight: 60 parts of polylactic acid, 27 parts of toughening particles, plasticizing 11 parts of antioxidants and 4 parts of antioxidants.

[0035] S2: Preparation of the PET base material layer: The raw materials of the PET base material layer were mixed evenly according to the weight part, and extruded through an extruder. The...

Embodiment 3

[0040] The invention provides a technical solution: a preparation method of a high-toughness and impact-resistant PET protective film, comprising the following specific steps:

[0041] S1: Select raw materials: including PET substrate layer, polylactic acid composite layer and PET release layer, the PET substrate layer is composed of the following raw materials in parts by weight: 90 parts of PET particles, 5 parts of nano-zirconia, terminal 7 parts of hydroxyl hyperbranched polyester hydroxyl, 2 parts of smooth degassing agent and 2 parts of leveling agent; the polylactic acid composite layer is composed of the following raw materials in parts by weight: 80 parts of polylactic acid, 45 parts of toughening particles, plasticizing 18 parts of antioxidants and 5 parts of antioxidants.

[0042]S2: Preparation of the PET base material layer: The raw materials of the PET base material layer were mixed evenly in parts by weight, and extruded through an extruder. The extrusion temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com