Reaction system and method for continuously synthesizing rubber vulcanization accelerator, namely dibenzothiazyl disulfide

A technology of dibenzothiazole disulfide and vulcanization accelerator, which is applied in the field of reaction systems for continuous synthesis of rubber vulcanization accelerator dibenzothiazole disulfide, can solve problems such as affecting the quality of DM, and is beneficial to environmental protection and improves the reaction yield. rate, and the effect of reducing the amount of backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

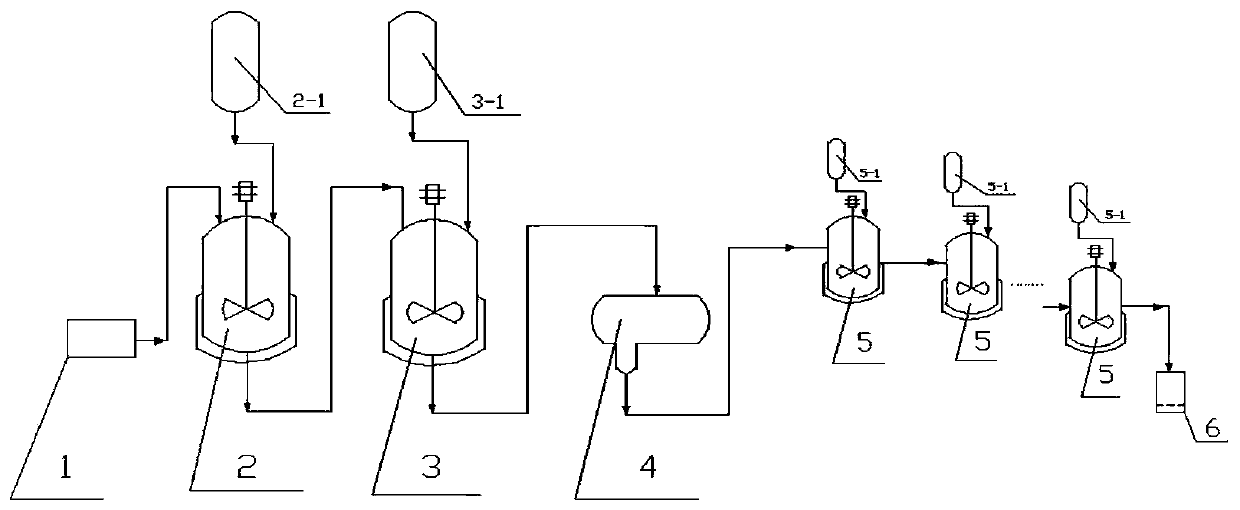

[0043] See attached figure 1 , the reaction system for the continuous synthesis of rubber vulcanization accelerator dibenzothiazole disulfide of the present invention comprises a crude M feeder 1, an ammonia solution kettle 2, an extraction kettle 3, a phase separation tank 4, a three-stage oxidation reaction kettle 5 and a filter press 6. Each device is connected in series through pipelines; the upper part of the ammonia water dissolution kettle 2 is provided with an ammonia water feeder 2-1, the upper part of the extraction kettle 3 is provided with an extraction agent feeder 3-1, and the upper part of the oxidation reaction kettle 5 at each level is provided with Oxidant feeder 5-1.

Embodiment 2

[0045] See attached figure 1 , the reaction system for the continuous synthesis of rubber vulcanization accelerator dibenzothiazole disulfide of the present invention comprises a crude M feeder 1, an ammonia solution kettle 2, an extraction kettle 3, a phase separation tank 4, a five-stage oxidation reaction kettle 5 and a filter press 6. Each device is connected in series through pipelines; the upper part of the ammonia water dissolution kettle 2 is provided with an ammonia water feeder 2-1, the upper part of the extraction kettle 3 is provided with an extraction agent feeder 3-1, and the upper part of the oxidation reaction kettle 5 at each level is provided with Oxidant feeder 5-1.

Embodiment 3

[0047] See attached figure 1 , the reaction system for the continuous synthesis of rubber vulcanization accelerator dibenzothiazole disulfide of the present invention comprises a crude M feeder 1, an ammonia solution kettle 2, an extraction kettle 3, a phase separation tank 4, a seven-stage oxidation reaction kettle 5 and a filter press 6. Each device is connected in series through pipelines; the upper part of the ammonia water dissolution kettle 2 is provided with an ammonia water feeder 2-1, the upper part of the extraction kettle 3 is provided with an extraction agent feeder 3-1, and the upper part of the oxidation reaction kettle 5 at each level is provided with Oxidant feeder 5-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com