Artificial core preparation method for irregular natural fractures in oil-water well cement sheath

A technology of natural fractures and artificial cores, which is applied in the field of simulating ternary elements, can solve problems such as poor connectivity of fractures, uncontrollable fracture direction and distribution, and difficulty in simulating the actual site, achieving process safety, low cost, and short cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

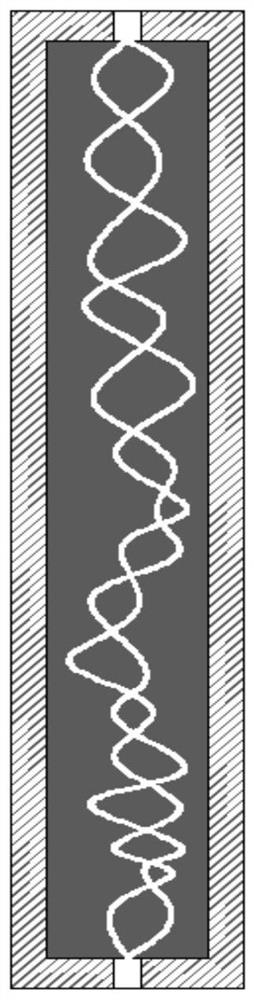

[0028] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The artificial core preparation method for simulating irregular natural fractures in cement sheaths of water wells containing ternary compound flooding, and its specific implementation steps are as follows:

[0029] a. Preparation of heavy cement slurry: According to the experimental requirements, mix cement (425#), barite powder, clay, quartz sand and water uniformly in the ratio of 4:1:1:1:2 to obtain a denser cement slurry. heavy cement paste;

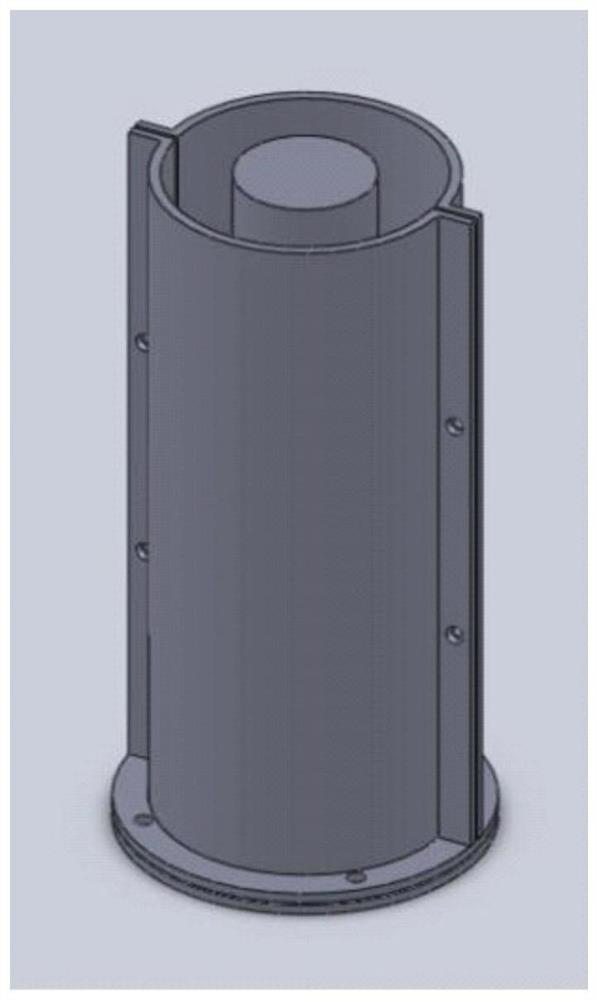

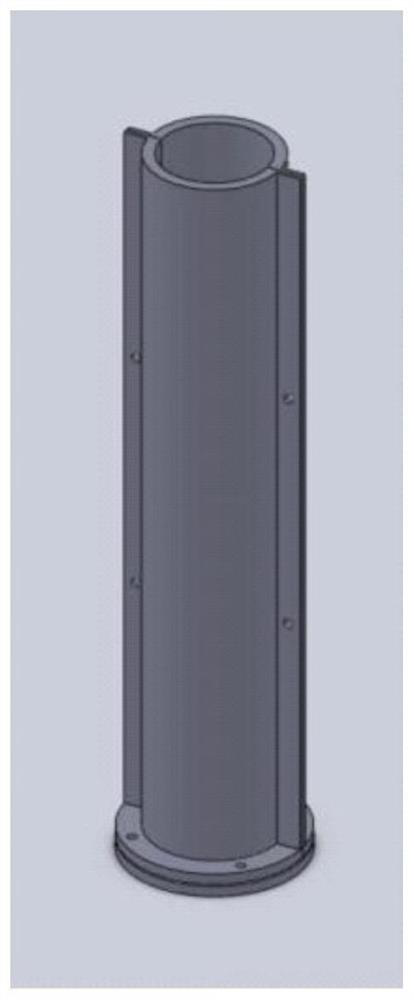

[0030] b. Preparation of heavy cement blocks: prepare ring-pillar molds (see figure 1 ), smooth the inner wall of the mold and apply butter evenly, and slowly pour the obtained heavy cement slurry into the mold and let it stand, waiting for the cement to solidify;

[0031] c. Making heavy cement particles: Take the solidified annular cement rock sample out of the model, knock the rock sample evenly with a tool to break it, and select from the cement fragments with a volume o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com