Rotary machine residual life prediction method of multi-layer bidirectional gating cycle unit network

A technology of rotating machinery and cyclic units, which is applied in the field of prediction of the remaining life of rotating machinery in a multi-layer bidirectional gated cyclic unit network, which can solve the problems of difficult rotating machinery, large changes in prediction results, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

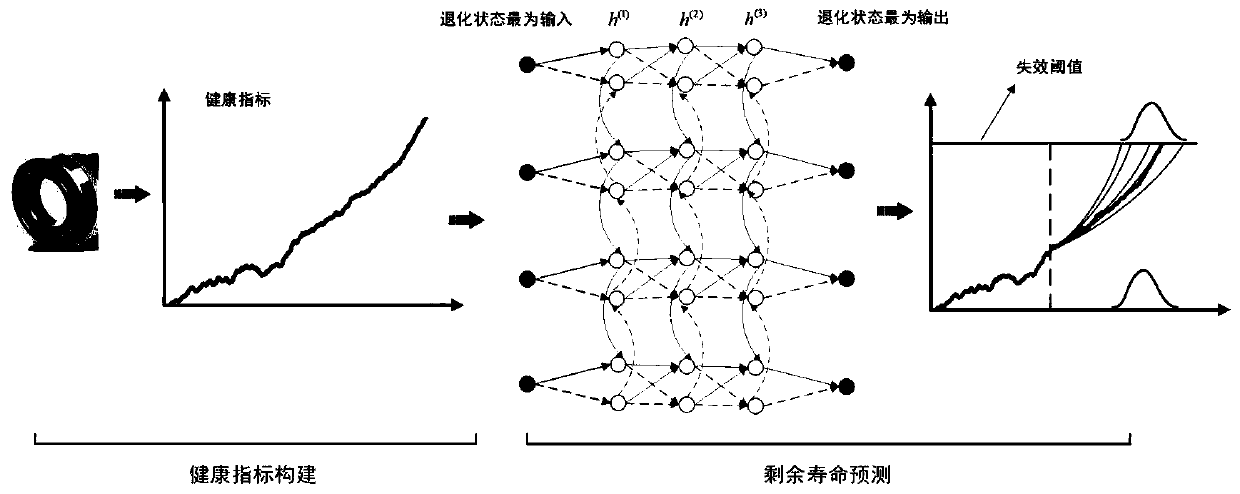

[0059] Such as figure 1 As shown, the method for predicting the remaining life of a rotating machine with a multi-layer bidirectional gated cyclic unit network in this embodiment includes the following steps.

[0060] Step 1, vibration signal collection: collect the vibration signals of the key parts of the rotating machinery.

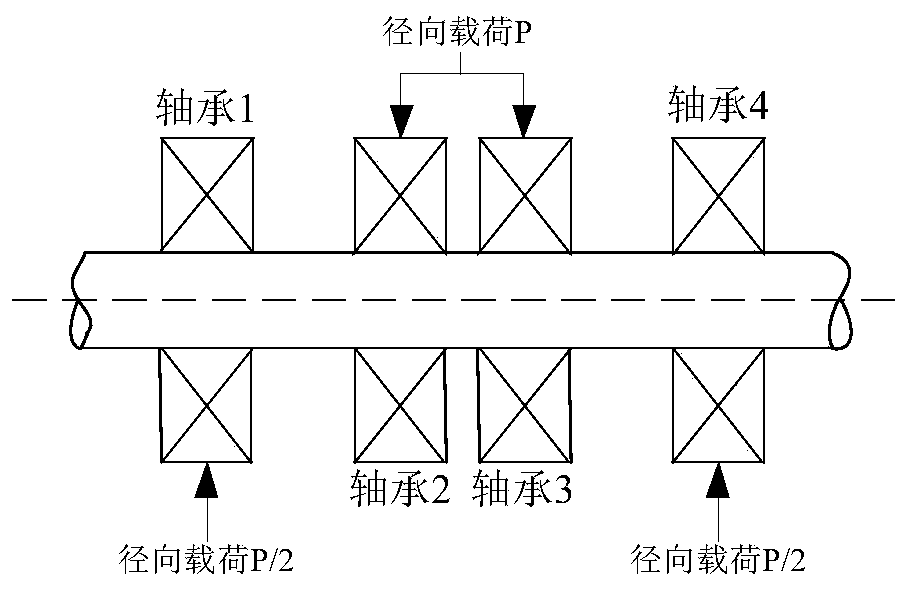

[0061] The key components of rotating machinery include bearings, gears or rotors, etc.; the acquisition method of vibration signals of key components is an existing technology. In this application, taking bearings as an example, ABLT-1A bearing life enhancement test bench. The test bench consists of test heads, test It consists of headstock, transmission system, loading system, lubrication system, electrical control system, testing and data acquisition system.

[0062] The test bench can install 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com