Dust removal system and method of corn straw briquetting forming machine

A technology of corn stalks and dust removal system, which is applied in presses, chemical instruments and methods, solid separation, etc. It can solve problems such as abnormal operation of machines, fragile briquetting molds, and low combustion value of briquetting products. Avoid soot-type pollution, save raw material costs, and have high efficiency in normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

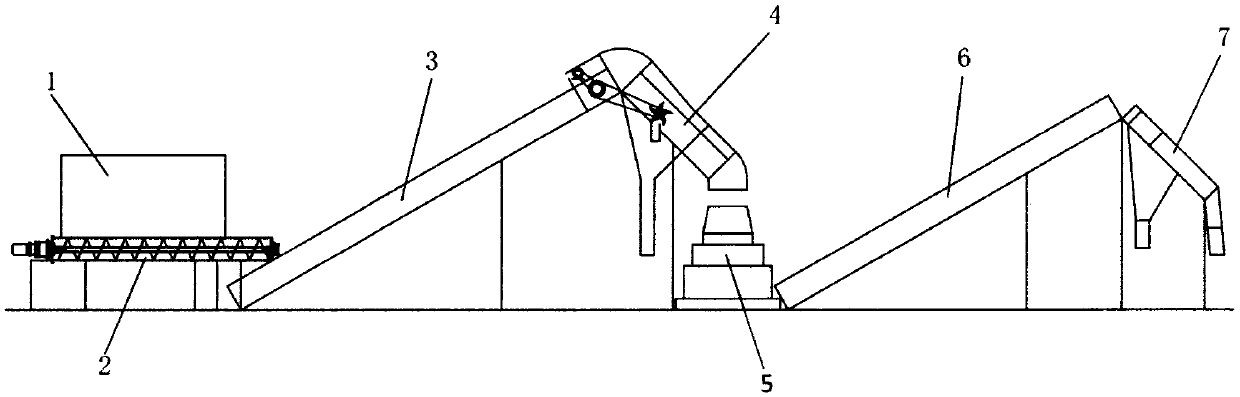

[0031] The invention guarantees no soil and no sundries. The product quality is good and the combustion value is high, which ensures the normal operation of the equipment and high efficiency. The qualified products fall into the second conveyor, and the second conveyor transports the products to the sorting machine, and the separated qualified products After bagging, the unqualified scraps fall into the bottom of the sorting machine and are transported out by a manpower trolley, and then returned to the silo.

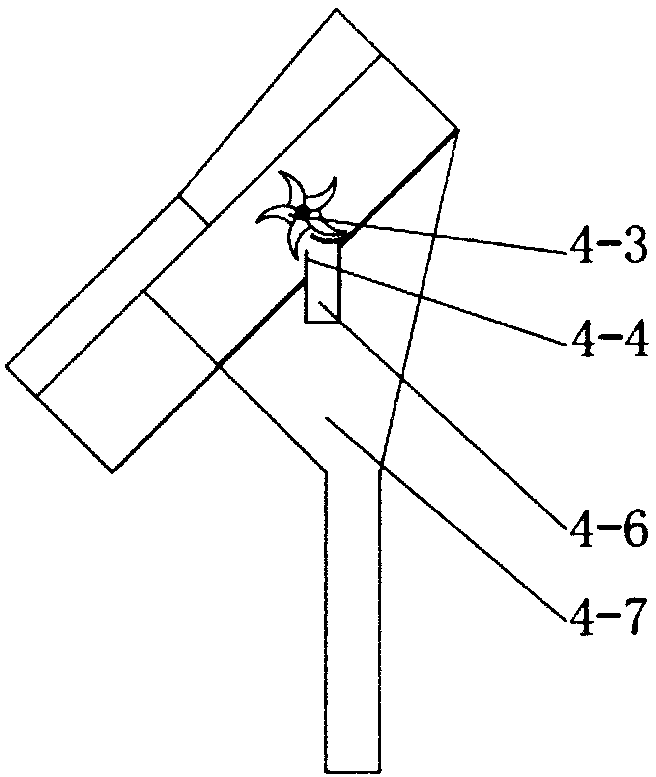

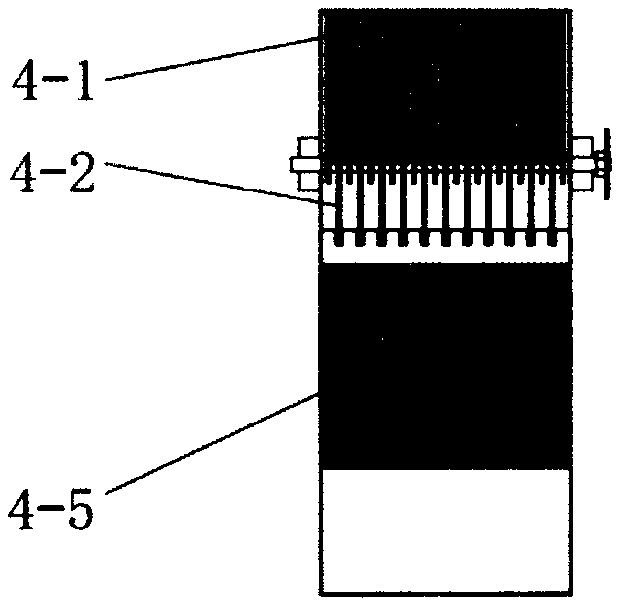

[0032] The application principle of the present invention will be described in detail below in conjunction with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com