Graphene and nano-titanium dioxide composite coating and its preparation method and application

A nano-titanium dioxide and composite coating technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve the problem of not being able to combine excellent properties, and achieve excellent anti-corrosion properties, easy control of operating conditions, and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

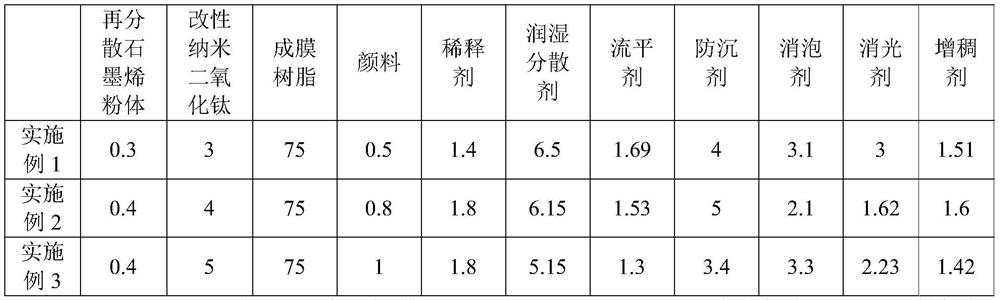

Examples

preparation example Construction

[0015] The preparation method of Graphene provided by the invention and nano-titanium dioxide composite coating (hereinafter also referred to as composite coating) comprises the following steps,

[0016] 1) The step of mixing the redispersible graphene powder and part of the film-forming resin to obtain the mixture;

[0017] 2) adding modified nano titanium dioxide to the mixture obtained in step 1) and grinding;

[0018] 3) adding the remaining film-forming resin to the ground product and mixing,

[0019] Wherein, the redispersed graphene powder is a powder obtained by drying the dispersion liquid after graphene is dispersed by using graphene as a raw material and using polyaniline oligomer and polyvinylpyrrolidone as a dispersant; The modified nano-titanium dioxide is a powder obtained by loading nano-titanium dioxide on titanium dioxide, and the particle size of the titanium dioxide is 8-100 μm.

[0020] Preferably, the amount of the redispersible graphene powder is such ...

Embodiment 1

[0069] 1) Preparation of redispersible graphene powder

[0070] 1 part by weight of graphene (purchased in Changzhou Sixth Element Materials Technology Co., Ltd., 5 layers of graphene, particle size is 10-55 μm) and 10 parts by weight of polyaniline oligomer (purchased in Shandong Baihong New Material Co., Ltd., the average molecular weight is 7000) and polyvinylpyrrolidone (purchased from Shanghai Xinyu Biotechnology Co., Ltd., the average molecular weight is 10000) mixed (the weight ratio of polyaniline oligomer and polyvinylpyrrolidone is 1:2) , to obtain a graphene mixture;

[0071] After the graphene mixture is ultrasonically dispersed, it is filtered at 25°C for 30 minutes to obtain the filtrate, and the filtrate is ultrasonically dispersed again and then centrifuged to obtain a uniformly dispersed graphene dispersion. Among them, the conditions for ultrasonic dispersion Both: the power is 500W, the time is 2 hours, the conditions of centrifugation are: the speed is 150...

Embodiment 2

[0078] 1) Preparation of redispersible graphene powder

[0079] 1 weight part of graphene (purchased in Changzhou Sixth Element Materials Technology Co., Ltd., 5 layers of graphene, particle size is 10-55 μm) and 20 weight parts of polyaniline oligomer (purchased in Shandong Baihong New Material Co., Ltd., the average molecular weight is 9000) and polyvinylpyrrolidone (purchased from Shanghai Xinyu Biotechnology Co., Ltd., the average molecular weight is 10000) mixed (the weight ratio of polyaniline oligomer and polyvinylpyrrolidone is 1:10) , to obtain a graphene mixture;

[0080] After the graphene mixture is ultrasonically dispersed, it is filtered at 25°C for 30 minutes to obtain the filtrate, and the filtrate is ultrasonically dispersed again and then centrifuged to obtain a uniformly dispersed graphene dispersion. Among them, the conditions for ultrasonic dispersion Both: the power is 500W, the time is 2 hours, the conditions of centrifugation are: the speed is 15000 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com