Special-shaped hole processing method based on spatially shaped femtosecond laser layered scanning

A technology of femtosecond laser and space shaping, which is applied in the field of femtosecond laser application, to achieve the effect of avoiding uneven ablation, high special-shaped hole processing, and high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: processing special-shaped holes on the surface of a PMMA sample (polymethyl methacrylate) with a space-shaping femtosecond laser.

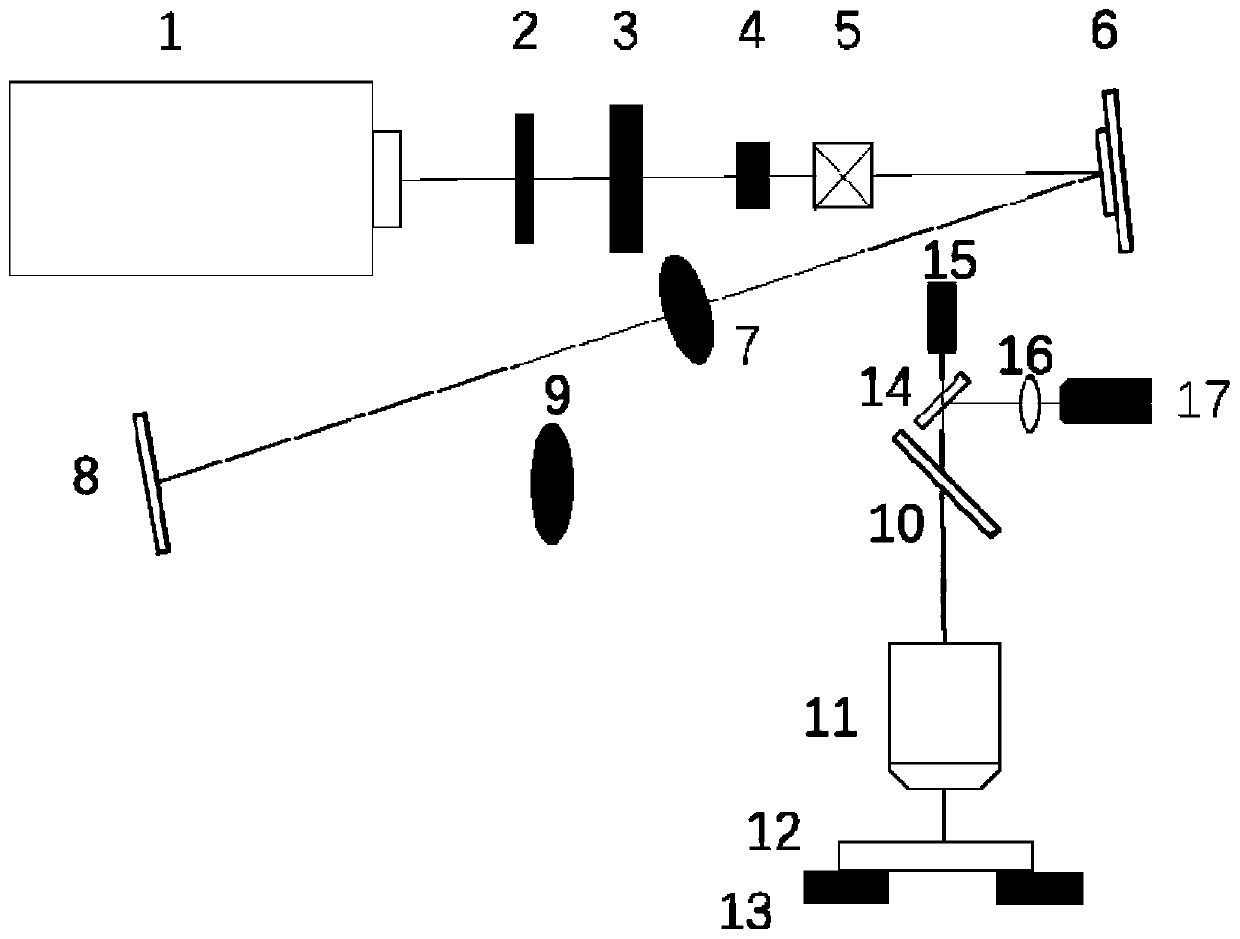

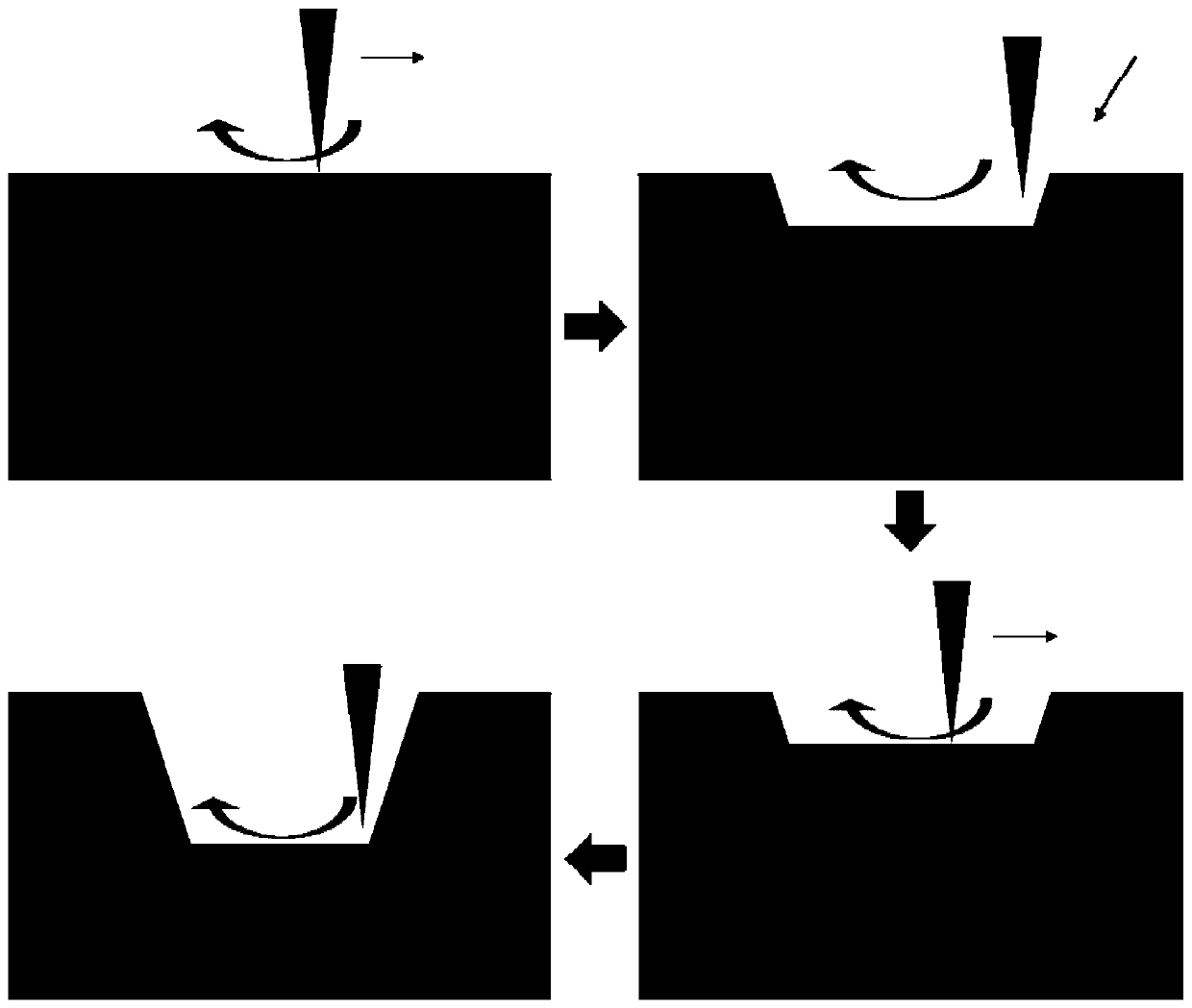

[0035] The specific processing steps of this embodiment are as follows: turn on the laser, wait for 20-30 minutes to stabilize the light output of the laser, and place each optical path element according to the figure 1Sequentially placed on the optical bench, and then the femtosecond laser is collimated and adjusted so that it can be irradiated on the surface of the PMMA sample without shaping and focusing. The femtosecond laser pulse repetition frequency of the femtosecond laser 1 is set to 1000 Hz, and the beam waist diameter before laser focusing is controlled at 5 mm. Under the operation of the control program of the six-dimensional translation stage 13, the focal plane of the processing objective lens 11 is determined at the end of the processing optical path, so that the focus of the processing objective lens 11 is exac...

Embodiment 2

[0037] Embodiment 2: Processing special-shaped holes on the surface of PDMS sample (polydimethylsiloxane) with space-shaping femtosecond laser.

[0038] The specific processing steps of this embodiment are as follows: turn on the laser, wait for 20-30 minutes to stabilize the light output of the laser, and place each optical path element according to the figure 1 Sequentially placed on the optical bench, and then the femtosecond laser is collimated and adjusted so that it can be irradiated on the surface of the PDMS sample without shaping and focusing. The femtosecond laser pulse repetition frequency of the femtosecond laser 1 is set to 1000 Hz, and the beam waist diameter before laser focusing is controlled at 7 mm. Under the operation of the control program of the six-dimensional translation stage 13, the focal plane of the processing objective lens 11 is determined at the end of the processing optical path, so that the focus of the processing objective lens 11 is exactly lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com