Emulsified asphalt for non-stick wheel, and preparation method thereof

A technology of emulsified asphalt and non-stick wheels, which is applied to building components, building insulation materials, buildings, etc. It can solve the problems of high requirements for emulsification equipment, affecting construction efficiency, and high production costs, and achieves good anti-viscosity effect. The preparation method is simple and practical , Fast demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

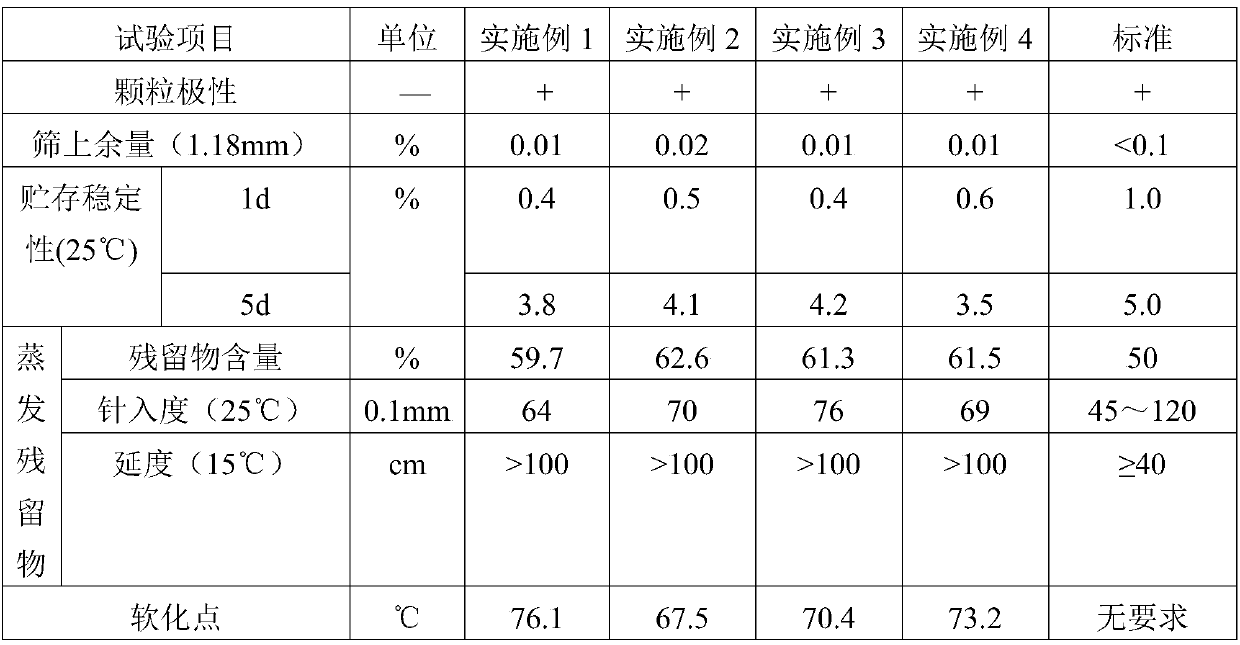

Examples

Embodiment 1

[0026] A non-stick wheel emulsified asphalt, made of the following raw materials in parts by weight: 30 parts of 110# asphalt, 30 parts of 10# asphalt, 8 parts of sulfur powder, 1.5 parts of cationic emulsifier cetyltrimethylammonium bromide 0.05 parts of polyacrylamide, 2 parts of calcium chloride, 1 part of hydrochloric acid, 5 parts of carboxylated styrene-butadiene latex, and 50 parts of water.

Embodiment 2

[0028] A non-stick wheel emulsified asphalt, made of the following raw materials in parts by weight: 55 parts of 110# asphalt, 10 parts of 10# asphalt, 3 parts of sulfur powder, 3 parts of cationic emulsifier alkylpropylenediamine, polyacrylamide 0.02 parts, 1 part of calcium chloride, 3 parts of hydrochloric acid, 2 parts of carboxylated styrene-butadiene latex, 40 parts of water.

Embodiment 3

[0030] A non-stick wheel emulsified asphalt, made of the following raw materials in parts by weight: 43 parts of 110# asphalt, 20 parts of 10# asphalt, 6 parts of sulfur powder, cationic emulsifier cetyltrimethylammonium bromide 1 0.04 parts of polyacrylamide, 0.5 parts of calcium chloride, 1.5 parts of hydrochloric acid, 4 parts of carboxylated styrene-butadiene latex, and 45 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com