Method for determining q-axis current compensation value of permanent magnet synchronous motor and pulsation suppression metho

A permanent magnet synchronous motor and determination method technology, applied in motor control, torque ripple control, motor generator control and other directions, can solve the problems of time lag, high complexity of torque ripple suppression, limited memory, etc., to avoid Time lag, simple operation, accurate calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

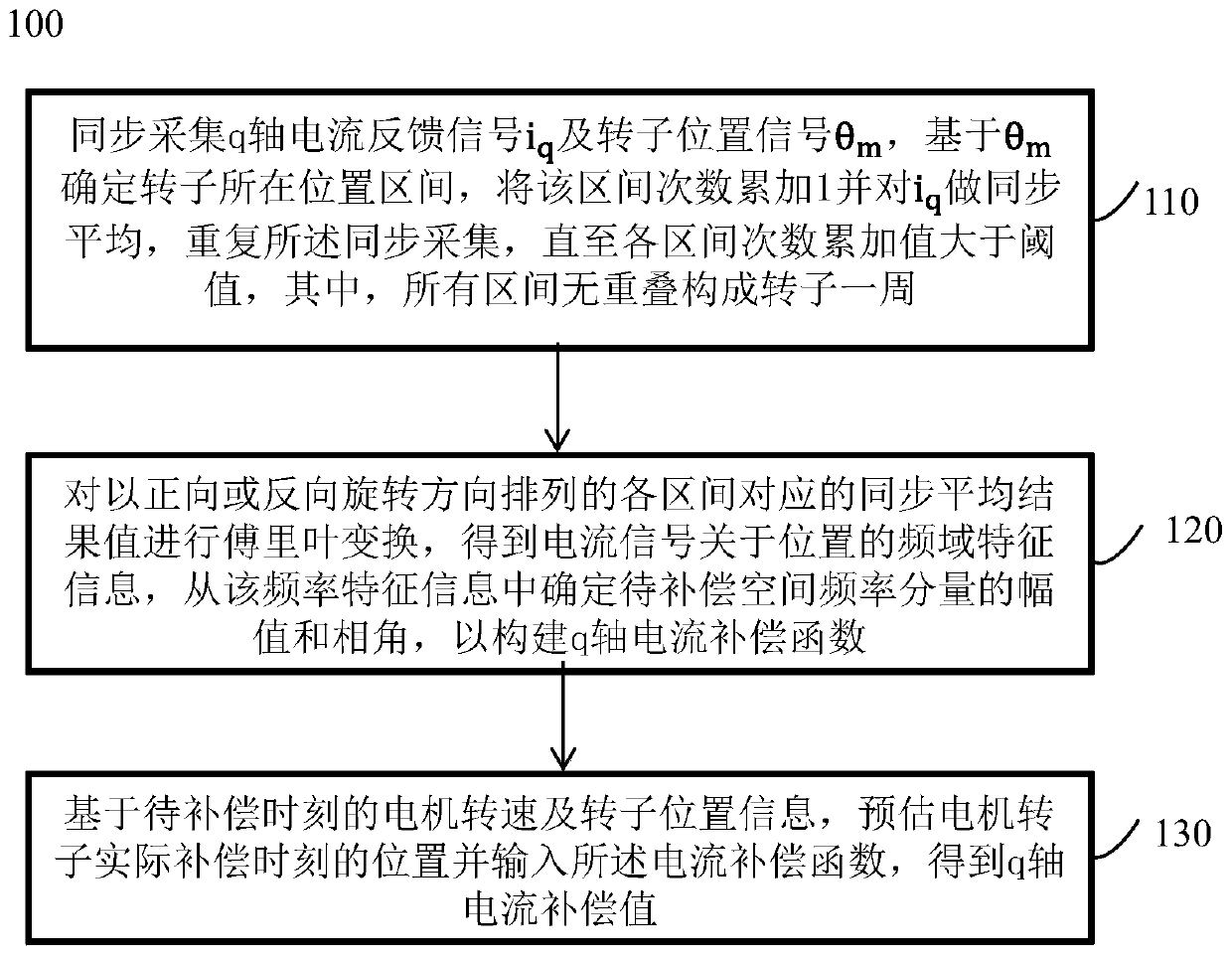

[0040] A method 100 for determining the q-axis current compensation value of a permanent magnet synchronous motor, such as figure 1 shown, including:

[0041] Step 110, synchronously collect the q-axis current feedback signal iq and the rotor position signal θ m , based on θ m Determine the position interval of the rotor, add 1 to the number of times in this interval and q Do synchronous averaging, and repeat the synchronous acquisition until the cumulative value of the number of intervals is greater than the threshold, wherein all intervals do not overlap to form a rotor cycle;

[0042] Step 120: Perform fast Fourier transform on the synchronous average result values corresponding to the intervals arranged in the forward or reverse rotation direction to obtain the frequency domain characteristic information of the current signal about the position, and determine the space to be compensated from the frequency characteristic information The amplitude and phase angle of the...

Embodiment 2

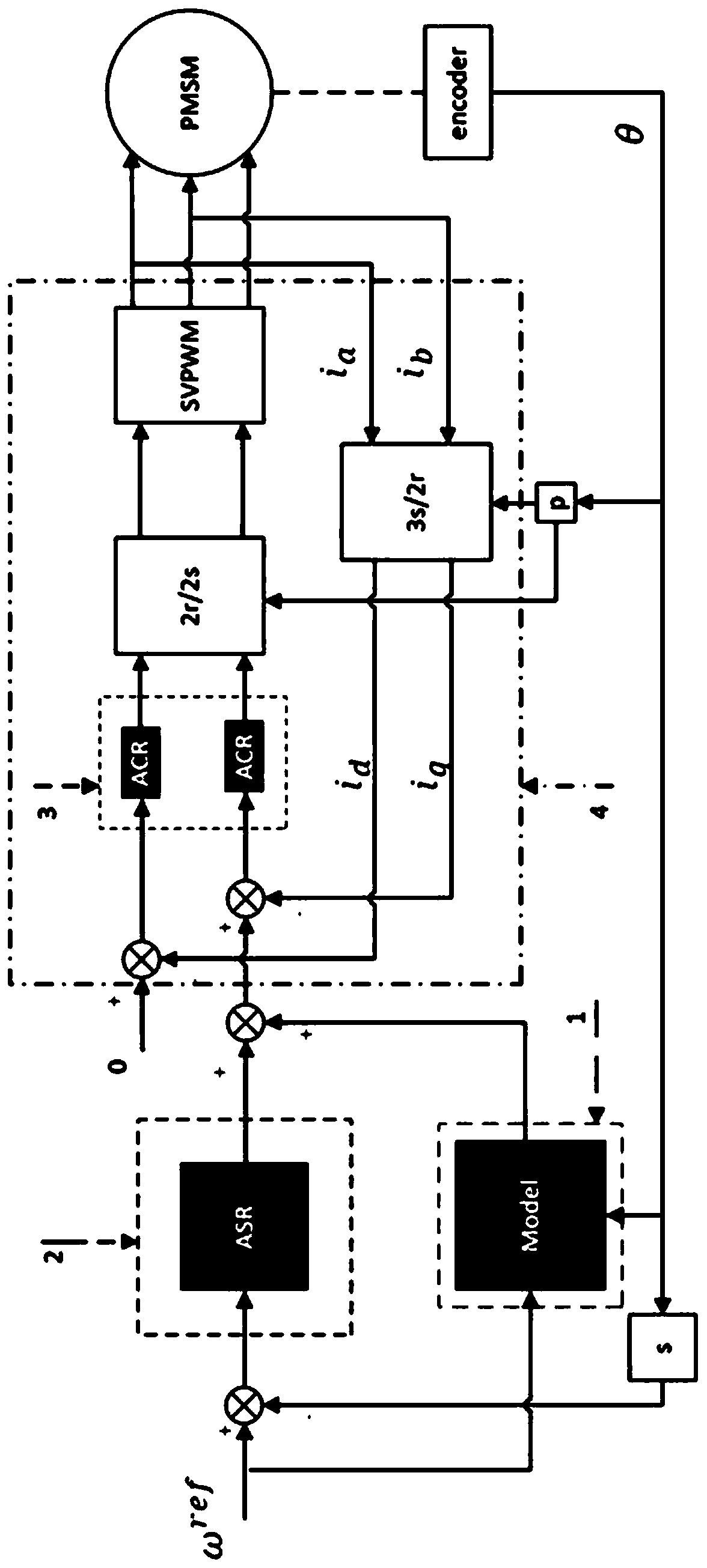

[0065] A method 200 for suppressing torque ripple of a permanent magnet synchronous motor, comprising:

[0066] Step 210, debug the control system of the motor to make the motor work stably, adjust and optimize the speed loop to match the electromechanical characteristics of the load, and adjust the current loop to ensure the current response;

[0067] Step 220, using any method for determining the q-axis current compensation value of the permanent magnet synchronous motor described in the first embodiment above, to obtain the q-axis current compensation value;

[0068] Step 230 , superimposing the q-axis current compensation value with the q-axis current command actually output by the speed loop, and using it as an input to the current loop to complete torque ripple compensation suppression.

[0069] It should be noted that in step 210, before determining the current compensation function, the control system of the motor is debugged first, so that the motor can work stably, a...

Embodiment 3

[0079] A storage medium, in which instructions are stored, and when the computer reads the instructions, the computer is made to execute any method for compensating the q-axis current of a permanent magnet synchronous motor as described in the first embodiment above and / or the above embodiment 2. Any method for suppressing torque ripple of a permanent magnet synchronous motor.

[0080] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com