Salted egg yolk and malt sandwich biscuit and preparation method thereof

A technology of sandwich biscuits and salted egg yolk, which is applied in the field of salted egg yolk malt sandwich biscuits and its preparation, can solve the problems of limiting the expansion of biscuit taste, and achieve the effect of low cost, crisp taste and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

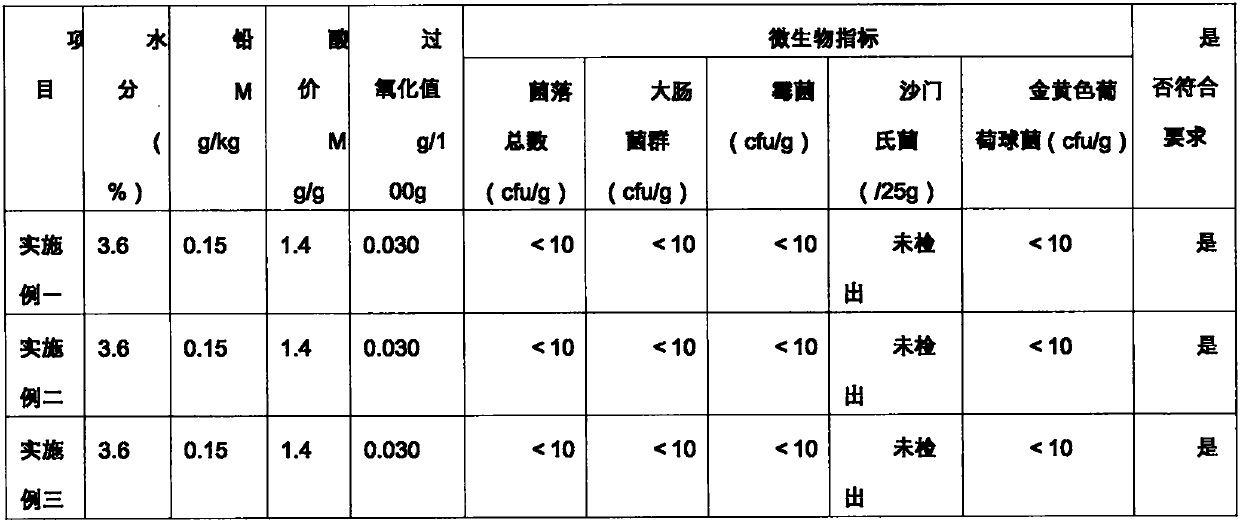

Examples

Embodiment 1

[0033] Embodiment 1, a salted egg yolk malt sandwich biscuit of the present invention, the sandwich layer includes the following raw materials in parts by weight: 10 parts of white granulated sugar, 10 parts of trehalose, 125 parts of malt syrup, 25 parts of water, 1 part of table salt, and sorbitol 25 parts, 5 parts of modified starch, 4 parts of pectin, 10 parts of salted egg yolk, 1 part of butter, 12 parts of glycerin, 0.2 part of citric acid, 0.2 part of edible essence; the outer layer includes the following raw materials in parts by weight: flour 175 5 parts of butter, 5 parts of anhydrous cream, 35 parts of white sugar powder, 3 parts of table salt, 25 parts of palm oil, 6 parts of salted egg yolk, 2 parts of whole milk powder, 2 parts of malt syrup, 22 parts of water, sodium bicarbonate 2 parts, 0.1 part of enzyme preparation, 0.01 part of sodium metabisulfite, 0.2 part of food flavor.

[0034] The volume ratio of the sandwich layer to the whole salted egg yolk malt sa...

Embodiment 2

[0050]Embodiment 2, a salted egg yolk malt sandwich biscuit of the present invention, the sandwich layer includes the following raw materials in parts by weight: 15 parts of white granulated sugar, 10 parts of trehalose, 125 parts of malt syrup, 20 parts of water, 2 parts of table salt, and sorbitol 20 parts, 4 parts of modified starch, 4 parts of pectin, 12 parts of salted egg yolk, 1 part of butter, 10 parts of glycerin, 0.15 part of citric acid, 0.2 part of food flavor; the outer layer includes the following raw materials in parts by weight: flour 180 7 parts of butter, 6 parts of anhydrous butter, 37 parts of white sugar powder, 3 parts of table salt, 25 parts of palm oil, 7 parts of salted egg yolk, 1 part of whole milk powder, 1 part of malt syrup, 20 parts of water, sodium bicarbonate 1.5 parts, 0.1 parts of enzyme preparation, 0.01 parts of sodium metabisulfite, 0.4 parts of food flavor.

[0051] The volume ratio of the sandwich layer to the whole salted egg yolk malt ...

Embodiment 3

[0067] Embodiment 3, a salted egg yolk malt sandwich biscuit of the present invention, the sandwich layer includes the following raw materials in parts by weight: 15 parts of white granulated sugar, 10 parts of trehalose, 125 parts of malt syrup, 20 parts of water, 1.5 parts of table salt, sorbitol 20 parts, 4 parts of modified starch, 4 parts of pectin, 12 parts of salted egg yolk, 1.5 parts of butter, 10 parts of glycerin, 0.15 part of citric acid, 0.5 part of food flavor; the outer layer includes the following raw materials in parts by weight: flour 165 6 parts of butter, 7.5 parts of anhydrous butter, 40 parts of white sugar powder, 2.5 parts of table salt, 27.5 parts of palm oil, 8 parts of salted egg yolk, 1 part of whole milk powder, 1 part of malt syrup, 17.5 parts of water, sodium bicarbonate 1 part, 0.15 part of enzyme preparation, 0.02 part of sodium metabisulfite, 0.5 part of food flavor.

[0068] The sandwich layer accounts for 25% of the volume ratio of the whole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com