Preparation method of hydrophilic anti-fog film with wear resistance and frost resistance

A hydrophilic, thin-film technology, applied in the coating and other directions, can solve the problems of poor mechanical properties, complicated operation process of super-hydrophilic anti-fog surface, etc., and achieve the effects of good durability, convenient operation and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

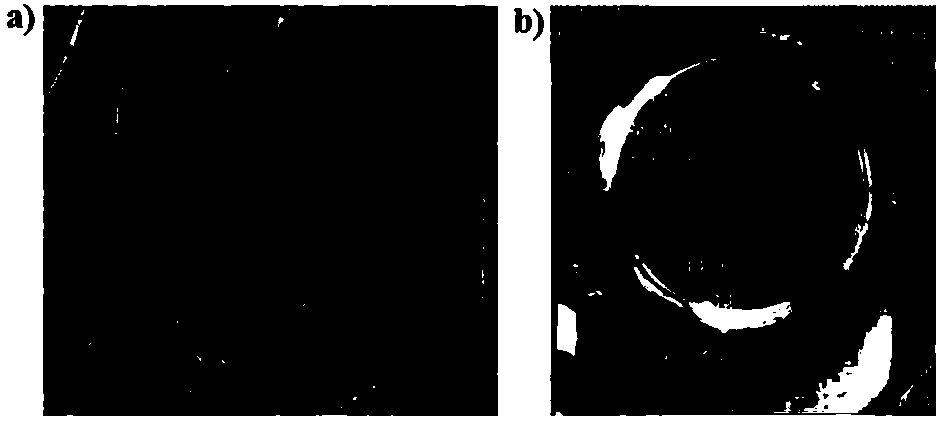

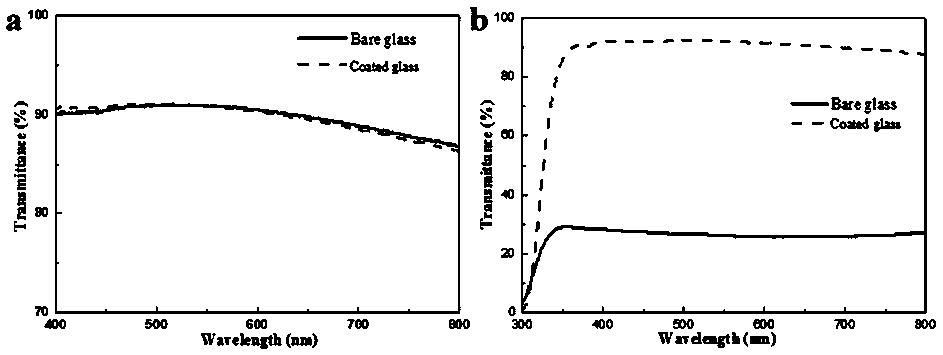

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a hydrophilic anti-fog film with wear resistance and frost resistance, comprising the following steps:

[0033] (1) Prepare a reactant solution with a certain concentration;

[0034] (2) Spin coating and dry.

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with specific embodiments.

[0036] Step 1: Prepare a certain concentration of reactant solution

[0037] In one embodiment, this step can be specifically carried out as follows: First, put the glass slide in a beaker and pass through acetone, absolute ethanol, and deionized water for 15 minutes of ultrasonication. After the ultrasonication is completed, put it in a 60°C oven for drying, and cool it for later use. Prepare 0.1-2 mg / mL cellulose solution, 1-10 mg / mL iron ion solution and 250-2000 mg / mL polyacrylic acid solution, ...

Embodiment 1

[0046] In this embodiment, a hydrophilic anti-fog film with wear resistance and frost resistance is prepared according to the following steps:

[0047] Step 1. Prepare a certain concentration of reactant solution

[0048] Put the glass slice in a beaker and pass it through acetone, absolute ethanol, and deionized water for 15 min in order to sonicate. After the sonication, put it in a 60 ℃ oven to dry, and cool it for later use. Prepare 0.2 mg / mL cellulose solution, 1.2 mg / mL iron ion solution and 250 mg / mL polyacrylic acid solution, mix them in a volume ratio of 1:2:1, mix them evenly with a mixer, and let stand spare;

[0049] Step 2. Spin coating and drying

[0050] The cleaned glass sheet was treated with oxygen plasma for 2.0 min, and then the mixed solution prepared in step 1 was spin-coated on the glass sheet at a spin-coating speed of 1000 r / min for 5 s, and then placed at 90 °C Dry in an oven for 3 h.

Embodiment 2

[0052] In this embodiment, a hydrophilic anti-fog film with wear resistance and frost resistance is prepared according to the following steps:

[0053] Step 1. Prepare a certain concentration of reactant solution

[0054] Put the glass slice in a beaker and pass it through acetone, absolute ethanol, and deionized water for 15 min in order to sonicate. After the sonication, put it in a 60 ℃ oven to dry, and cool it for later use. Prepare cellulose solution of 1.0 mg / mL, iron ion solution of 2.5 mg / mL and polyacrylic acid solution of 500 mg / mL, and mix them in a volume ratio of 1:2:1, mix them evenly with a mixer, and let stand spare;

[0055] Step 2. Spin coating and drying

[0056] The cleaned glass sheet was treated with oxygen plasma for 3.0 min, and then the mixed solution prepared in step 1 was spin-coated on the glass sheet at a spin-coating speed of 700 r / min and a spin-coating time of 20 s, and then placed at 100 Dry in an oven at ℃ for 4 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com