QM1260 system high leveling powder fast curing polyester resin and its preparation method

A QM1260, 1. QM1260 technology, applied in the field of preparation of the above-mentioned polyester resin, can solve the problems of not being suitable for the QM1260 curing system, rapid curing cannot be realized, general leveling of the coating film, etc., to achieve the promotion of catalytic efficiency and curing reaction speed Fast, low softening point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

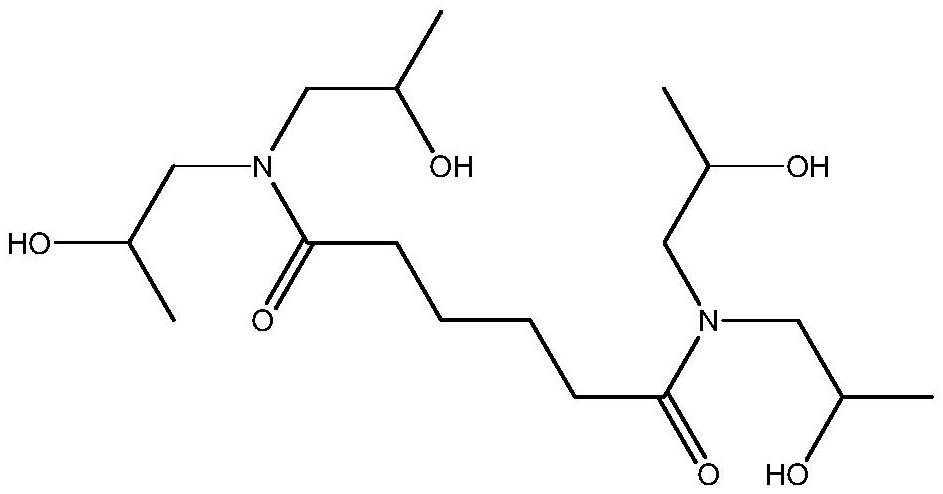

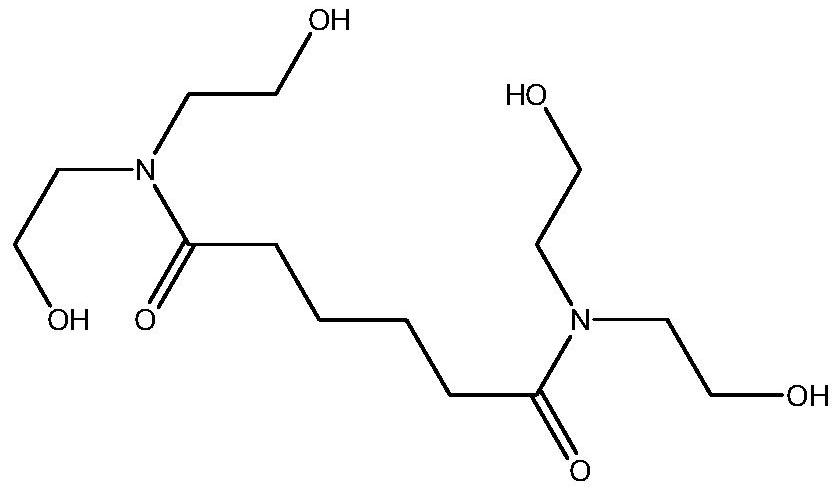

Image

Examples

Embodiment 1

[0048] The preparation method of QM1260 system high-leveling powder coating fast curing type polyester resin comprises the following steps:

[0049] (1) prepare the raw material of following molar quantity:

[0050] Diethylene glycol 16mol, diethanolamine 15mol, terephthalic acid 12mol, biphenyldicarboxylic acid 15mol, isophthalic acid 10mol, 1,6-hexanediol 7mol, octadecanedioic acid 9mol, monobutyltin oxide 0.1mol , antioxidant 1010 0.2mol, accelerator 0.02mol;

[0051] Add the catalyst, diethylene glycol, diethanolamine, terephthalic acid, and biphenyl dicarboxylic acid into the reactor, gradually raise the temperature to 180°C at 10°C / h, and fully esterify and polymerize at 180°C for 8 hours;

[0052] (2) When the hydroxyl value of the reactant reaches 50mgKOH / g, add isophthalic acid into the reactor to carry out sufficient esterification polymerization reaction, and slowly raise the temperature from 180°C to 220°C, and control the heating rate at 5°C / h , and insulation p...

Embodiment 6

[0077] The formulation of the general QM1260 system high leveling powder coating is usually as follows in parts by weight:

[0078]

[0079]

[0080] Paint coating preparation: Mix all materials according to the formula of QM1260 powder paint, extrude with twin-screw extruder, press into tablets, crush, and then crush and sieve the flakes to make powder paint. The powder coating is sprayed on the surface-treated aluminum plate with an electrostatic spray gun, and is rapidly cured at 180°C / 10min to obtain the powder coating.

[0081] Coating index detection is based on GB / T 21776-2008 "Powder Coatings and Coatings Testing Standard Guide"; boiling water resistance test GB 5237.4-2008 "Aluminum alloy building profiles part 4 powder sprayed profiles"; leveling level test basis According to JB-T 3998-1999 "Painting Leveling Test Method", the higher the leveling grade, the better the leveling of the coating film.

[0082] The product performance comparison of table 2 embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com