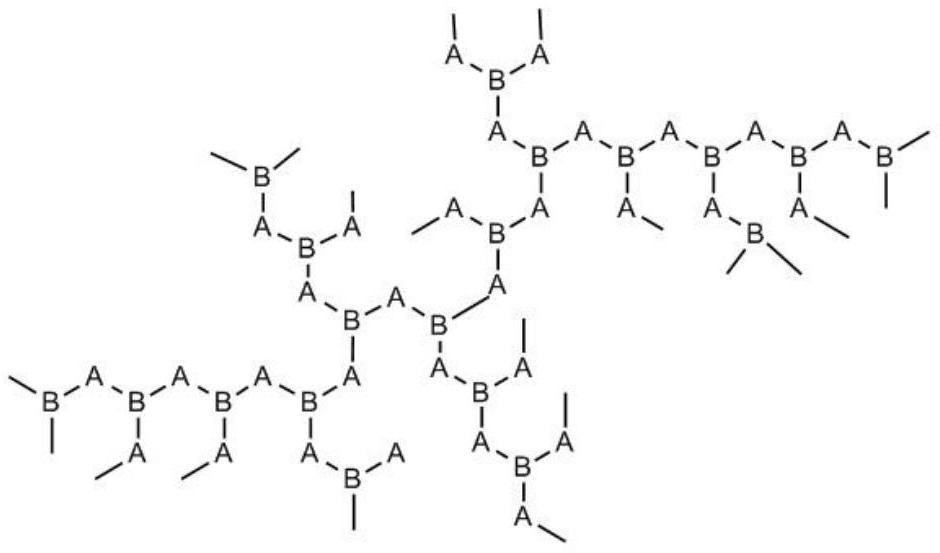

A kind of epoxy-terminated hyperbranched polyphosphate and preparation method thereof

A technology of polyphosphate and epoxy-terminated polyphosphate, which is applied in the field of epoxy-terminated hyperbranched polyphosphate and its preparation, can solve problems such as low viscosity, high molecular weight, and reduce production costs, and achieve good compatibility and high product quality. The effect of high quality and reduced production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of epoxy-terminated hyperbranched polyphosphate:

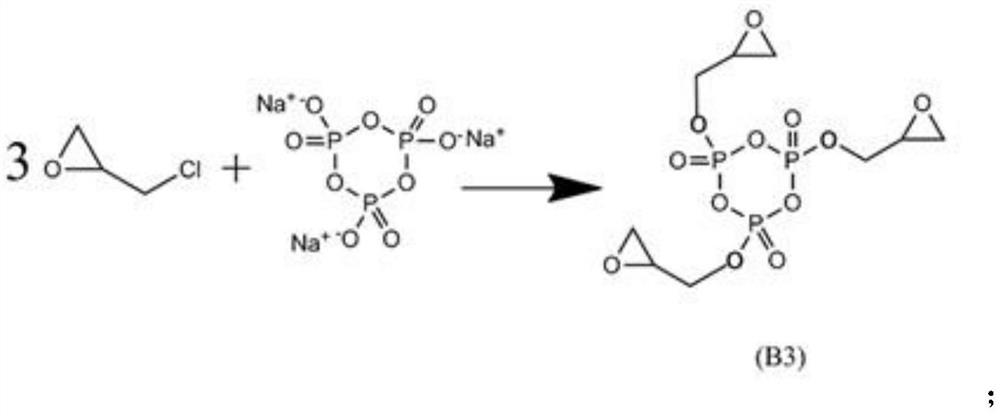

[0038] 1) Synthesis of Triglycidyl Trimetaphosphate (B3)

[0039] At room temperature, dissolve 100g of sodium trimetaphosphate with 300g of water, add 180g of organic solvent I dichloroethane, heat up to 50°C under stirring, add 1g of catalyst I tetraethylammonium bromide and stir until dissolved; then drop Add 100g of epichlorohydrin, control the reaction temperature at 40°C, keep warm, check the pH value of the system with a pH meter at intervals of 0.5h, adjust the pH to 7-8 with 10% sodium hydroxide solution, until the end of the reaction, the tricyclic trimetaphosphate is obtained The crude oxypropyl ester (B3) was washed with water and dried in vacuum to obtain the trimetaphosphate (B3) product.

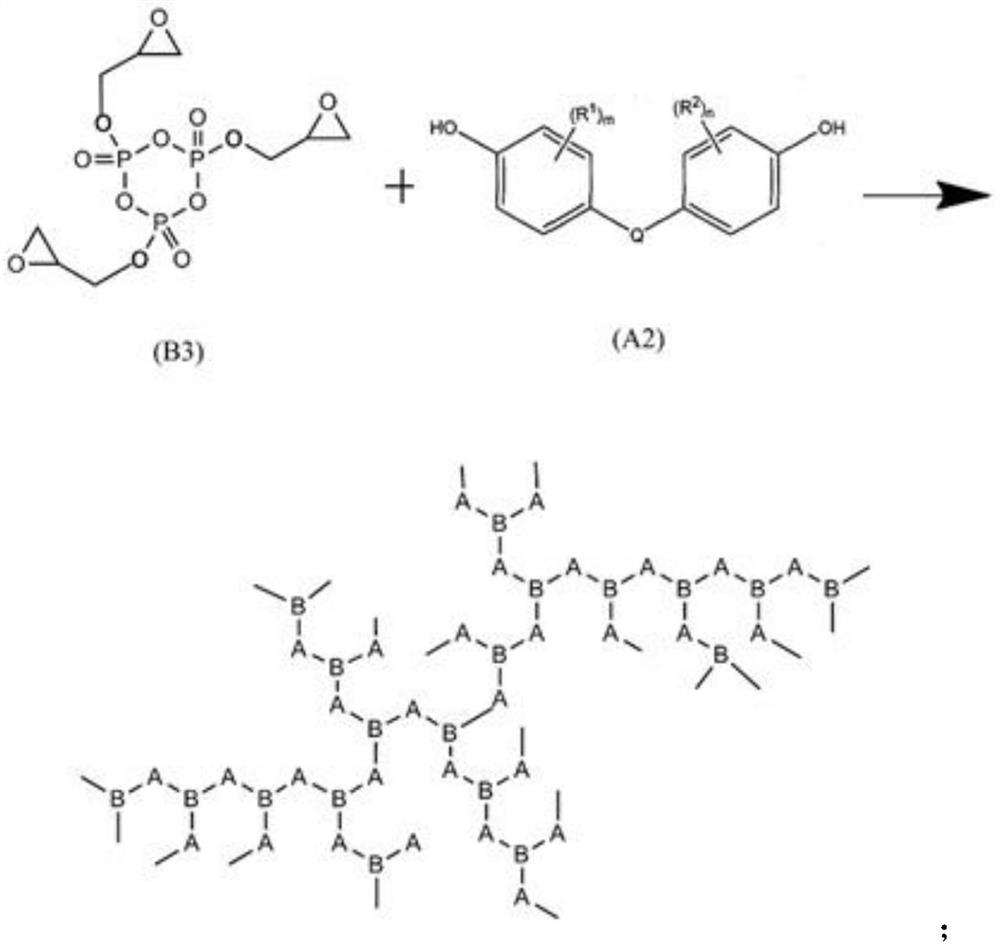

[0040] 2) Synthesis of epoxy-terminated hyperbranched polyphosphate

[0041] Get 140g of triglycidyl trimetaphosphate prepared in step 1), add to 840g organic solvent II toluene and dissol...

Embodiment 2

[0043] A preparation method of epoxy-terminated hyperbranched polyphosphate, comprising the following steps:

[0044] At room temperature, dissolve 100g of sodium trimetaphosphate in 500g of water, and after 750g of organic solvent I chloroform, raise the temperature to 60°C under stirring, then add 15g of catalyst I: 5g of tetraethylammonium bromide, 5g of tetrabutyl Ammonium bromide and 5g benzyltriethylammonium chloride were stirred until dissolved; then 200g epichlorohydrin was added dropwise, the reaction temperature was controlled at 60°C, and the temperature was kept at 0.5h intervals to detect the pH value of the system with a pH meter. Sodium hydroxide solution adjusts the pH to make it stable at pH 7-8, until the end of the reaction, the crude product of triglycidyl trimetaphosphate B3 is obtained, washed with water, and dried in vacuum to obtain the product of triglycidyl trimetaphosphate B3 .

[0045] 2) Synthesis of epoxy-terminated hyperbranched polyphosphate

...

Embodiment 3

[0048] A kind of preparation method of epoxy-terminated hyperbranched polyphosphate:

[0049] 1) Synthesis of Triglycidyl Trimetaphosphate (B3)

[0050] At room temperature, dissolve 100g of sodium trimetaphosphate with 400g of water, then add 465g of organic solvent I: 100g of dichloroethane, 120g of chloroform, 245g of carbon tetrachloride, heat up to 55°C under stirring, and add 8g of catalyst Ⅰ: Stir 4g of tetrabutylammonium bromide and 4g of benzyltriethylammonium chloride until dissolved; then add 150g of epichlorohydrin dropwise, keep the reaction temperature at 50°C, keep warm, and measure the pH of the system with a pH meter at intervals of 0.5h Value, adjust pH 7~8 with 20% sodium hydroxide solution, until reaction finishes, get trimetaphosphate trimetaphosphate (B3) crude product, wash with water, vacuum dry, get trimetaphosphate trimetaphosphate (B3) crude product, B3) Products.

[0051] 2) Synthesis of epoxy-terminated hyperbranched polyphosphate

[0052] Get ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com