Photothermal embedded thermal power peak shaving system and method

An embedded, photothermal technology, applied in solar thermal power generation, steam engine installations, mechanical power generated by solar energy, etc., can solve problems such as high investment costs, low energy utilization rate, and weak peak-shaving ability of thermal power, so as to improve flexibility performance, enhanced deep peak-shaving capability, and the effect of saving equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

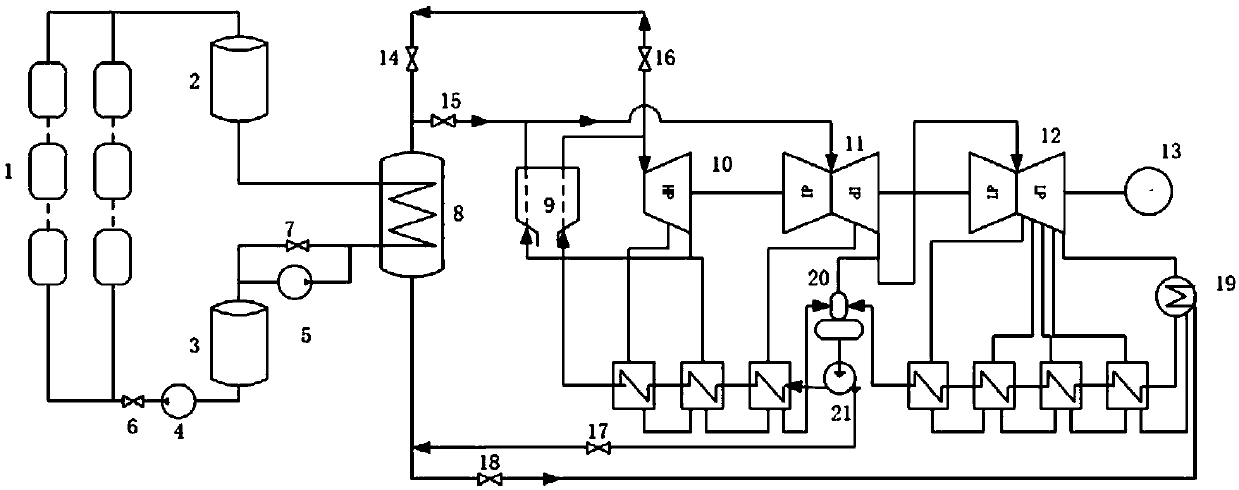

[0041] The heat collector 1 is a sunlight-focusing heat-collecting device, which can be tower-type, trough-type or disc-type heat collector, equipped with a bypass pipeline, a sun tracking system and a control system, and the inlet and outlet are respectively connected to the thermal medium storage station 2 , The cold working medium storage station 3 is connected.

[0042] Photothermal working medium is molten salt, ionic liquid (kCl, kOH, etc.), supercritical CO2 whose boiling point is higher than the boiler reheat steam temperature.

[0043]There are two parallel pipelines between the refrigerant storage station 3 and the heat exchanger 8, one of which is the passage of the refrigerant from the heat exchanger to the refrigerant storage station, and a regulating valve 7 is set, and the other is the flow of the refrigerant from the refrigerant Set the reverse pump 5 from the mass storage station to the heat exchanger channel.

[0044] The shells of the hot working medium sto...

Embodiment 2

[0051] The heat collector 1 is a sunlight-focusing heat-collecting device, which can be tower-type, trough-type or disc-type heat collector, equipped with a bypass pipeline, a sun tracking system and a control system, and the inlet and outlet are respectively connected to the thermal medium storage station 2 , The cold working medium storage station 3 is connected.

[0052] The photothermal working medium is supercritical CO2, the temperature is higher than 31.26°C, and the pressure is higher than 7.29MPa.

[0053] The solar thermal side is equipped with a CO2 injection device, and the supplementary CO2 can be extracted from the purified flue gas of the boiler.

[0054] There are two parallel pipelines between the refrigerant storage station 3 and the heat exchanger 8, one of which is the passage of the refrigerant from the heat exchanger to the refrigerant storage station, and a regulating valve 7 is set, and the other is the flow of the refrigerant from the refrigerant Set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com