Air-breathing engine plasma ignition system

An ignition system and plasma technology, applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of unable to achieve multiple ignition of the engine, unable to meet the requirements of wide-area ignition of the engine, etc., to solve the problem of multiple starts and maneuvers The effect of flight flameout, strong energy designability, and expansion of working airspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

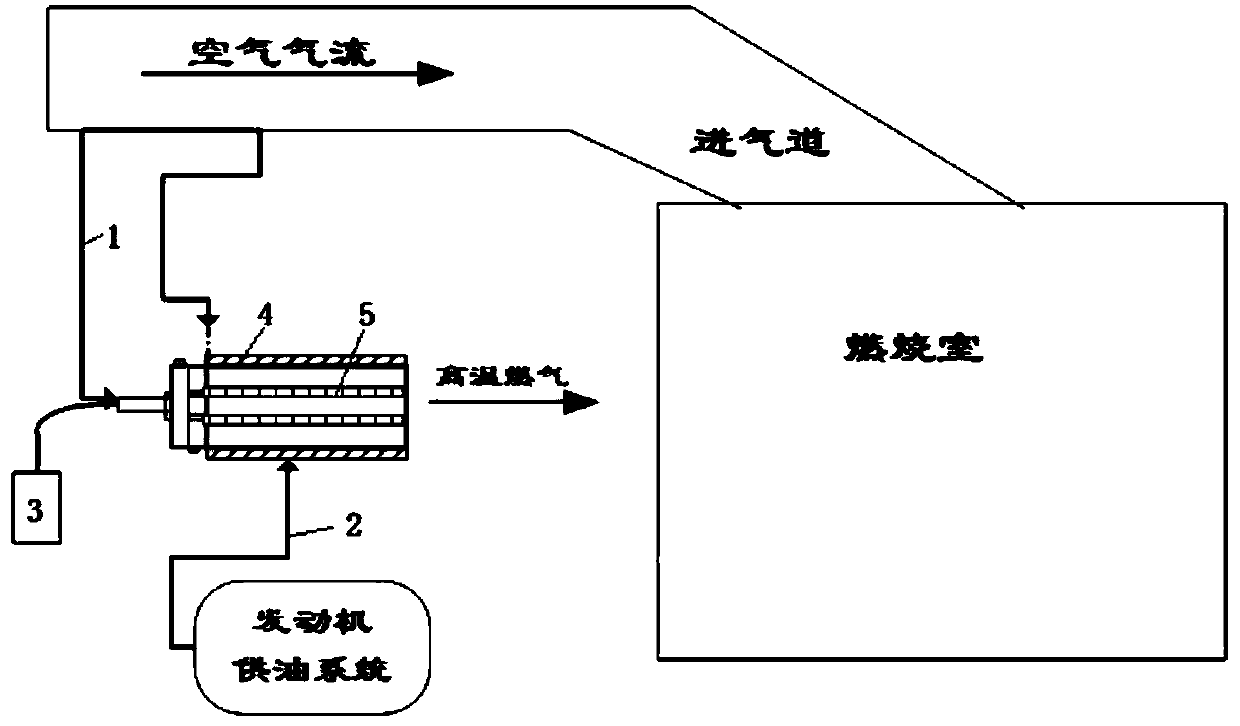

[0023] This embodiment provides an air-breathing engine plasma ignition system, see the attached figure 1 , including: bleed air pipeline 1, oil supply pipeline 2, power supply 3 and igniter housing;

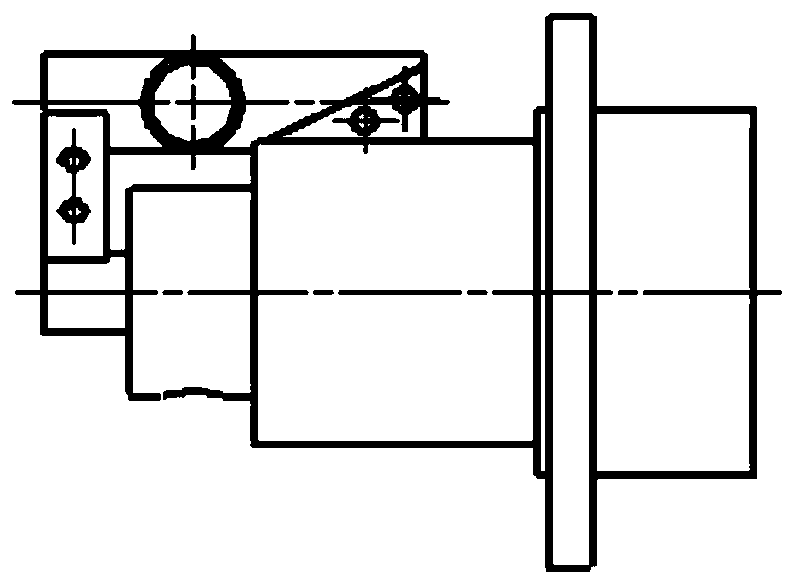

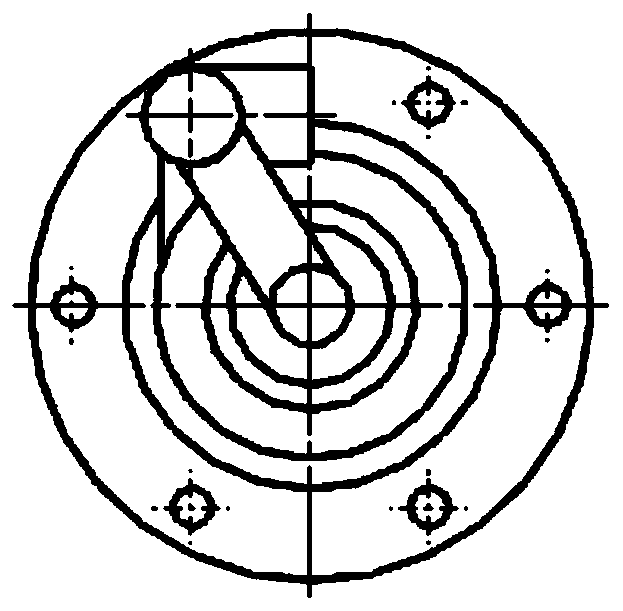

[0024] One end opening of the igniter housing is used as an air outlet, and is connected with the air inlet of the combustion chamber of the engine. A high-voltage electrode 5, a low-voltage electrode 4 and an insulating ring are arranged in the igniter housing, and the high-voltage electrode 5 and the low-voltage electrode 4 are both Hollow cylinder, the low-voltage electrode 4 is coaxially installed outside the high-voltage electrode 5, an annular cavity is formed between the high-voltage electrode 5 and the low-voltage electrode 4, and an insulating ring is installed at one end of the annular cavity to realize the high-voltage electrode 5 and the low-volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com