Environment-friendly cable with high brittleness resistance for low-temperature environment

A low temperature environment, environment-friendly technology, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as cracks, waste of resources, leakage of wire cores, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

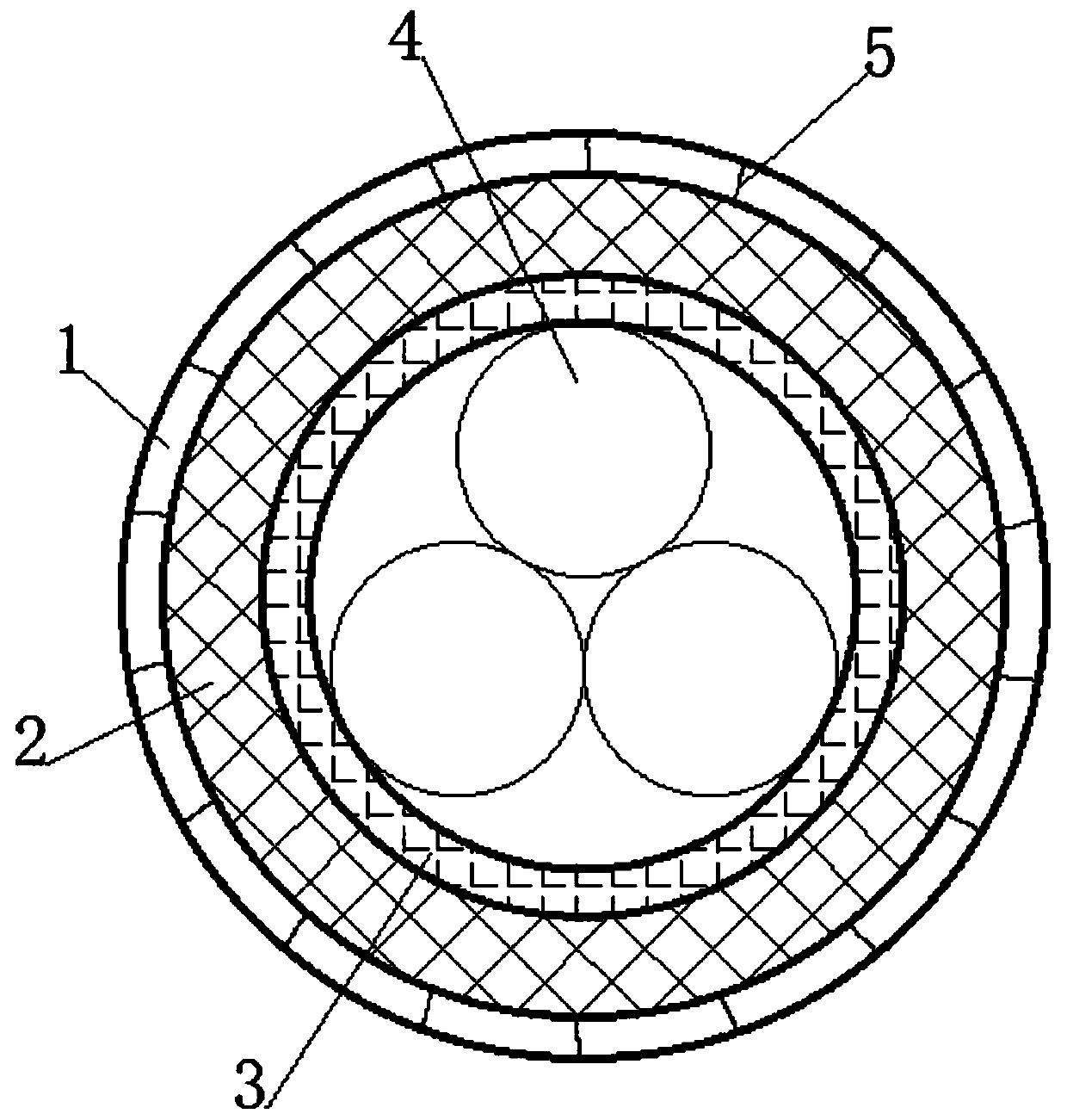

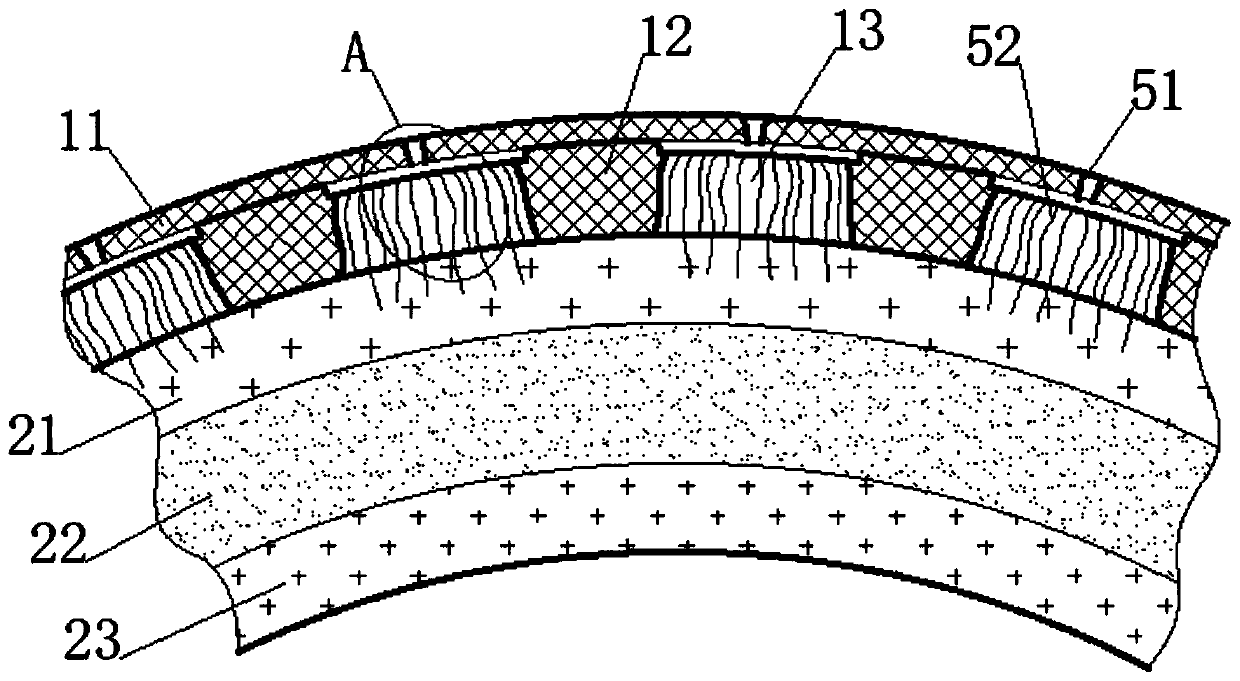

[0036] see figure 1 , an environmentally friendly cable with strong brittleness resistance for low temperature environments, comprising a plurality of cores 4, the outer ends of the plurality of cores 4 are wrapped with an inner insulating layer 3, and the outer end of the inner insulating layer 3 is wrapped with a softening interlayer 2, softening The outer end of the interlayer 2 is wrapped with an outer sheath 1 , and a plurality of evenly distributed inner and outer diffusion channels 5 are excavated in the outer sheath 1 .

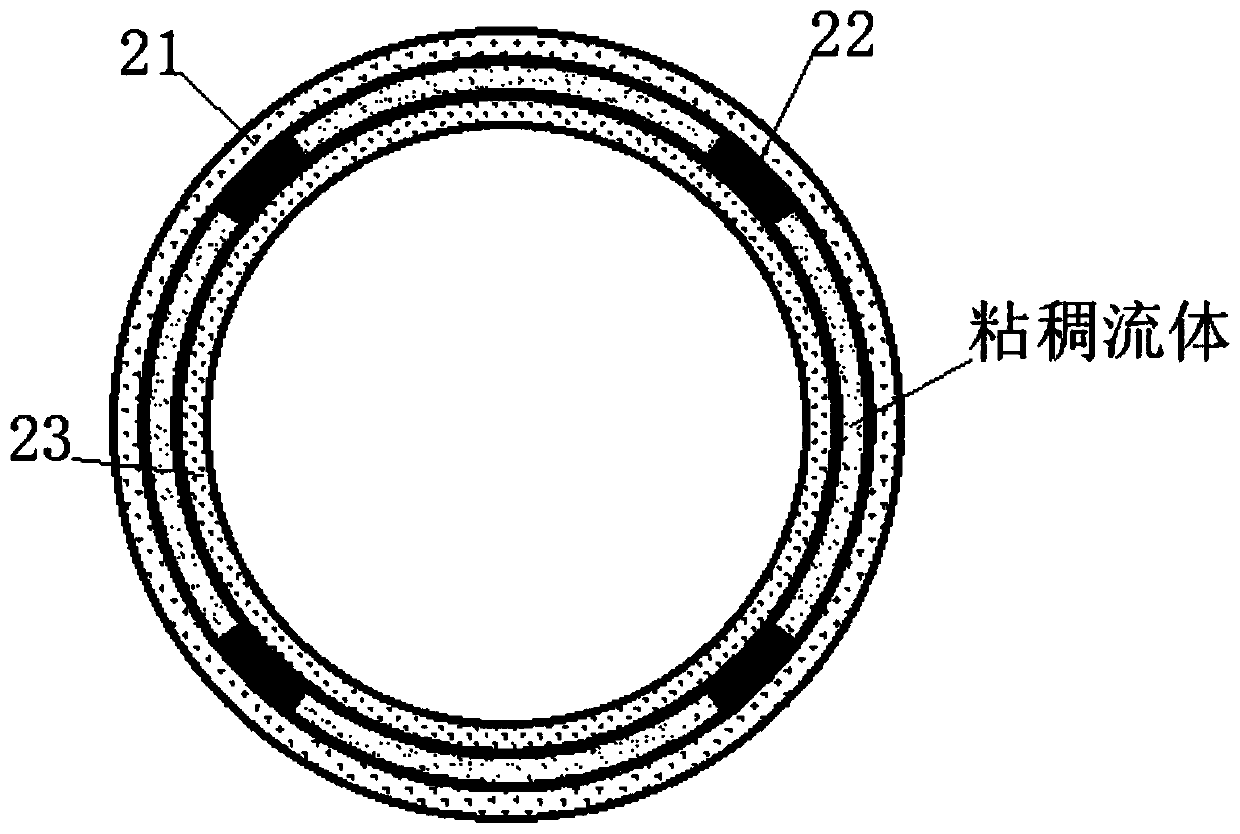

[0037] see figure 2 , the softening interlayer 2 includes a self-heating layer 21, a heat storage layer 22 and a thermal softening layer 23. The self-heating layer 21, the thermal storage layer 22 and the thermal softening layer 23 are sequentially arranged from outside to inside. A plurality of evenly distributed cavities are filled with viscous fluid, and the inner and outer diffusion channels 5 communicate with the outside world and the softened ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com