A production process of air suspension bearing high-speed frequency conversion motor impeller

A variable frequency motor and air suspension technology, applied in the field of variable frequency motor impellers, can solve the problems of unable to achieve automatic output, unable to continuously produce fan blades, reduce production output, etc., to improve quality and assembly efficiency, high degree of automation, reduce product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

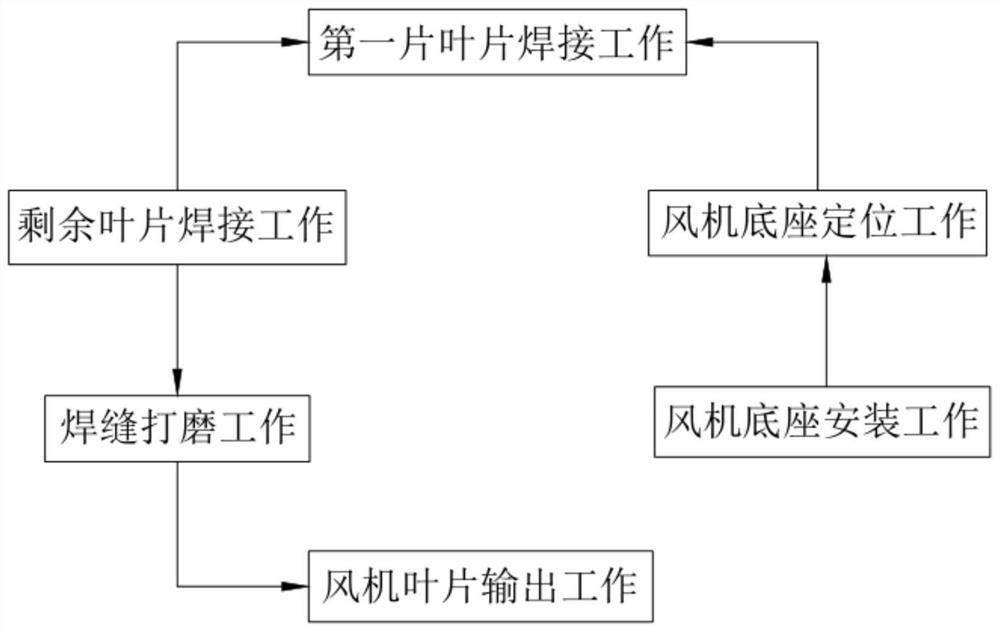

[0085] Such as figure 1 As shown, a production process of an air suspension bearing high-speed variable frequency motor impeller, including:

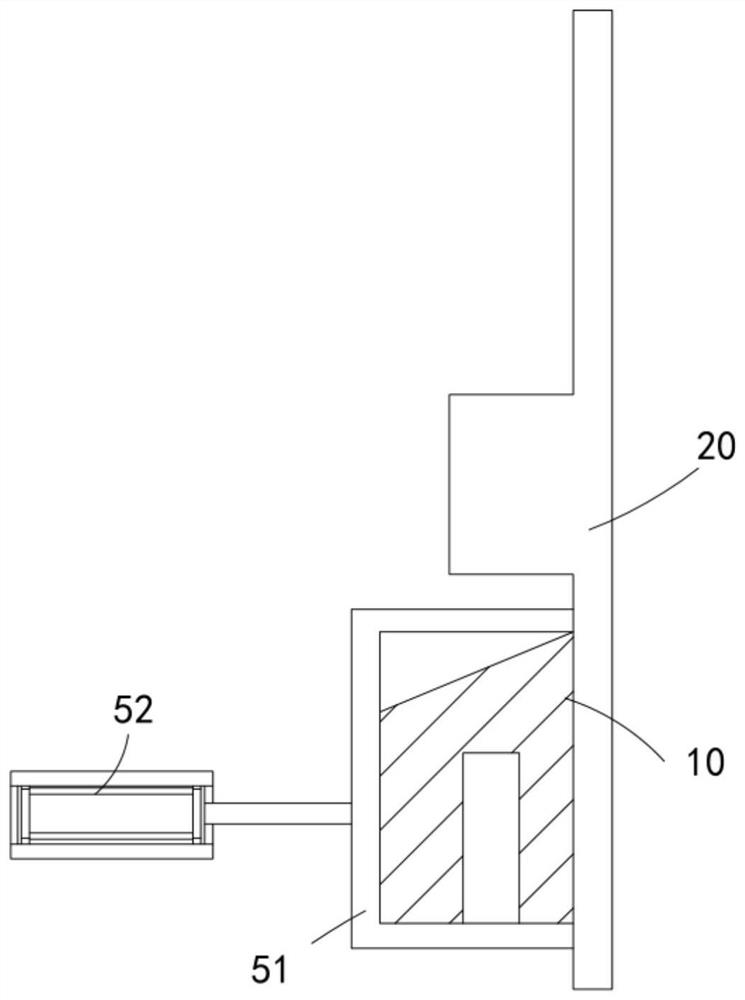

[0086] Step 1: Install the fan base. First, manually place the fan base on the sliding frame. Then, the three-claw manipulator 151 clamps the center of the fan base 20 and rotates it by 90°. Then, the telescopic tube 152 is extended to send the fan base 20 to On the sub-set shaft 1311 in the area of the feeding station 100;

[0087] Step 2, the fan base is positioned, the starting motor 125 rotates intermittently, and the sub-axis 121 rotates from the loading station 100 to the welding station 400, the gear a rotates under the action of the arc-shaped rack a1321, and the gear a is synchronized Drive the screw rod 1324 to rotate on the sub-shaft 121, the nut 1323 drives the pressure rod 1316 to move toward the sub-sleeve shaft 1311, and push the sliding block 1314 outward to tighten the fan base 20;

[0088] Step 3, the welding work ...

Embodiment 2

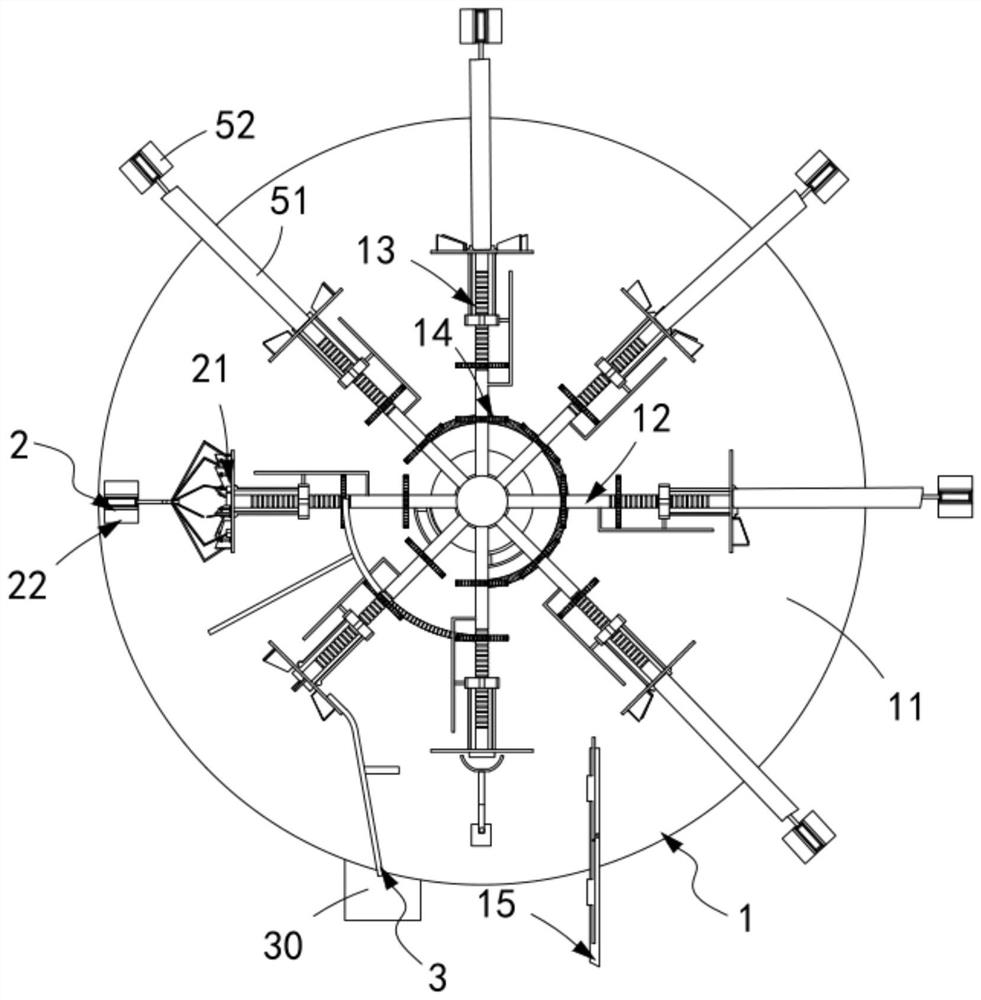

[0104] Such as figure 2 , Figure 7 As shown, an air suspension bearing high-speed variable frequency motor impeller production equipment includes:

[0105]Assembling device 1, described assembling device 1 comprises support table 11, the loading assembly 12 that is arranged on described support table 11, the tightening assembly 13 that is arranged on described feeding assembly 12, is used for driving feeding assembly 12 to complete Several groups of blades 10 are uniformly uploaded to the switching assembly 14 and the seat assembly 15 is automatically installed on the blades 10 to the feeding assembly 12;

[0106] Grinding device 2, said grinding device 2 includes several sets of hair removal assemblies 21 that are evenly arranged and each group is slidably arranged between two adjacent blades 10 after welding, and is used to drive several groups of hair removal assemblies 21 to move synchronously The drive assembly 22; and

[0107] An output device 3, the output device 3...

Embodiment 3

[0145] Such as Figure 19 , Figure 18 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of brevity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0146] further, such as Figure 19 , Figure 18 As shown, the hair removal assembly 21 includes:

[0147] A connection block 211, the connection block 211 is slidably arranged on the support table 11 and located at the center between any two blades 10; and

[0148] The control piece 212, the control piece 212 is arranged in pairs on both sides of the connection block 211 and is respectively polished corresponding to the welded part of the blade 10, which includes a spring b213 fixedly connected with the connection block 211, and the spring b213 The other end of b213 is fixedly connected to the vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com