Full-fermented fresh flower-polished glutinous rice wine and production method therefor

A production method and technology for glutinous rice wine, which are applied in the preparation of alcoholic beverages, etc., can solve the problems of high sugar content, short shelf life, single taste, etc., and achieve the effects of bright color, sweet taste, and elegant wine body and aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

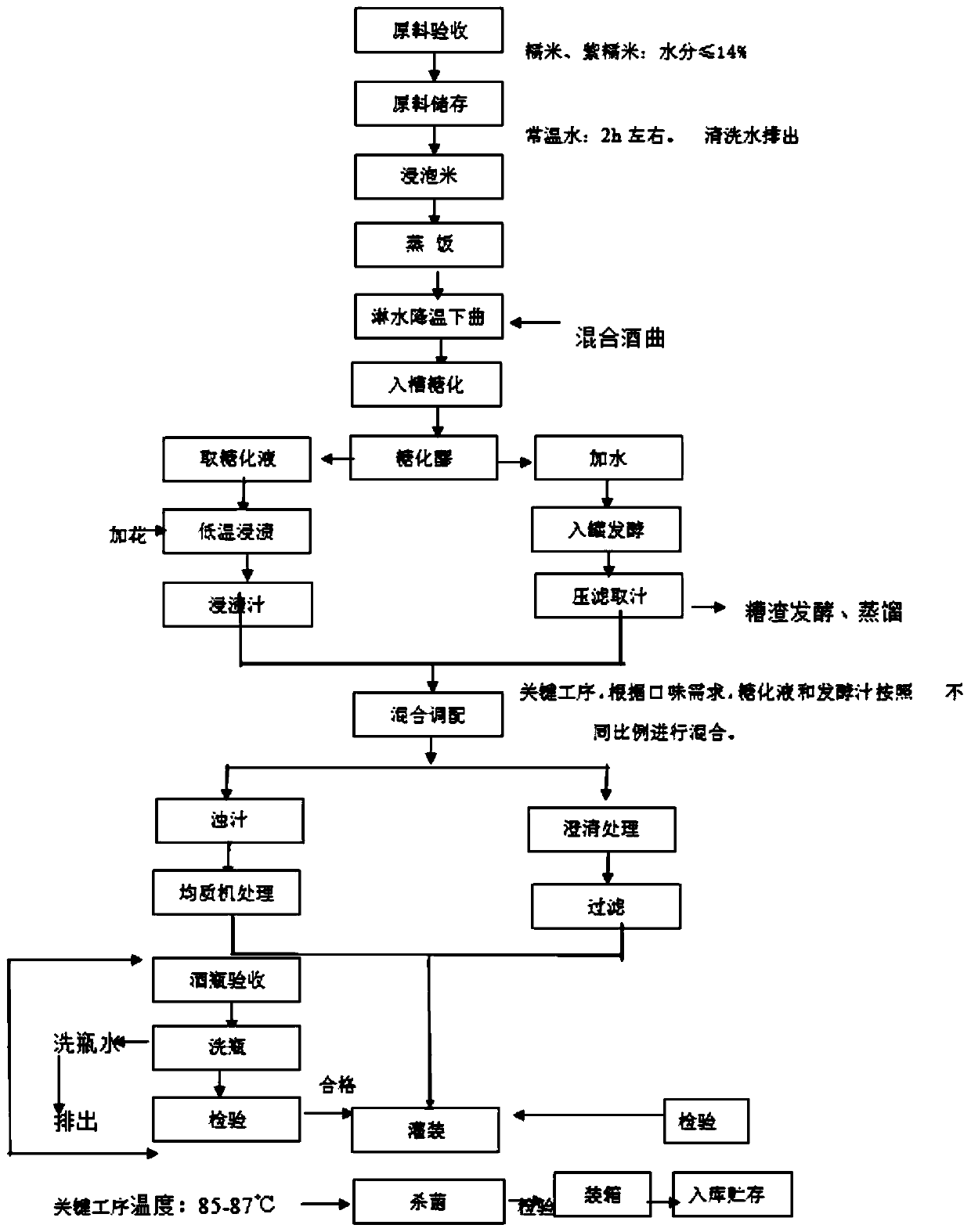

Method used

Image

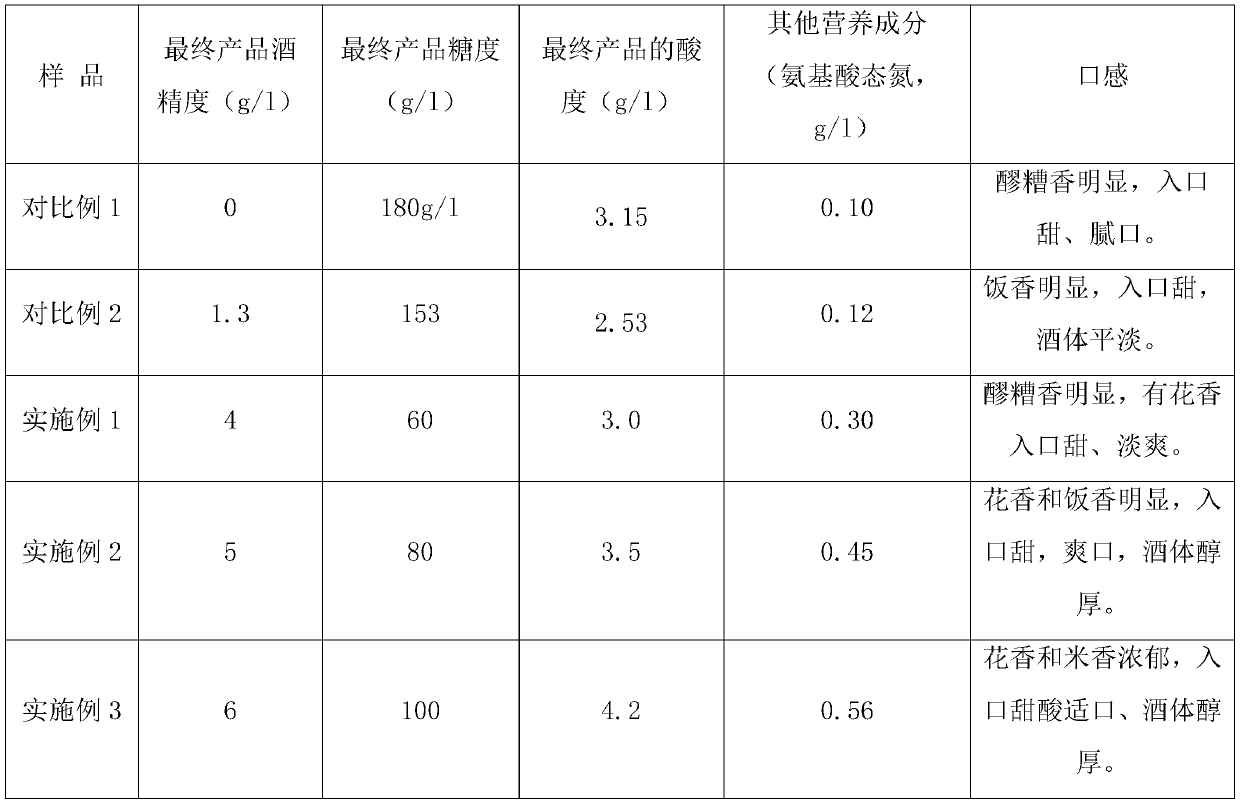

Examples

Embodiment 1

[0035] 1) Selection of raw materials: glutinous rice (the weight ratio of white glutinous rice and purple glutinous rice is 4:1) has a moisture content of ≤14%, and a mildew rate of ≤2%. Roses are picked on sunny days, ventilated in time, and petals are picked to ensure no insects , mildew and disease.

[0036] 2) Soaking: Soak the mixture of glutinous rice and purple rice in water for 15 hours to make the rice grains absorb enough water for easy steaming, and then release the soaking water to obtain mixture A;

[0037] 3) steaming rice: steaming the soaked mixture A through a rice steaming machine to obtain glutinous rice;

[0038] 4) After cooling down, pour the cooked rice through low-temperature clean water to 38°C, and then blow it to 26°C through a fan. The wind in the fan can take away the excess water in the rice, making the cooked rice loose;

[0039] 5) Mixed koji: Angel sweet rice koji and strains are used to optimize the mixing of koji (increase the sweetness of t...

Embodiment 2

[0053] 1) Selection of raw materials: glutinous rice (the weight ratio of white glutinous rice and purple glutinous rice is 6:1) has a moisture content of ≤14%, and a mildew rate of ≤2%. Roses are picked on sunny days, ventilated in time, and petals are picked to ensure no insects , mildew and disease.

[0054] 2) Soaking: Put the qualified glutinous rice into the soaking barrel through the elevator, and soak it in tap water for 17 hours, so that the rice grains can absorb enough water to facilitate steaming.

[0055] 3) steaming rice: steaming the soaked mixture A through a rice steaming machine to obtain glutinous rice;

[0056] 4) After cooling down, pour the cooked rice through low-temperature pure water to 26°C, and then blow it to 26°C through a fan. The wind in the fan can take away the excess water in the rice, making the cooked rice loose;

[0057] 5) Mixed koji: Angel sweet rice koji and optimized strains (increase the sweetness of the mash and inhibit the growth of a...

Embodiment 3

[0071] 1) Selection of raw materials: glutinous rice (the weight ratio of white glutinous rice and purple glutinous rice is 8:1) has a moisture content of ≤14%, and a mildew rate of ≤2%. Roses are picked on sunny days, ventilated in time, and petals are picked to ensure no insects , mildew and disease.

[0072] 3) Soaking: Put the qualified glutinous rice into the soaking bucket through the elevator, and soak it in tap water for 15-16 hours, so that the rice grains can absorb enough water to facilitate steaming.

[0073] 4) steaming rice: steaming the soaked mixture A through a rice steaming machine to obtain glutinous rice;

[0074] 5) Lower the temperature of the koji, pour the mixture A through low-temperature purified water to 27°C, and add the mixed koji;

[0075] 6) Mixed koji: Angel sweet rice koji and optimized strains (increase the sweetness of the mash and inhibit the growth of acetic acid bacteria);

[0076] 7) Saccharification in the tank, the cooked rice added w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com