Spraying drying room

A drying room and box technology, applied in spray booths, injection devices, combustion methods, etc., can solve the problems of high operation and maintenance costs, uncoordinated, low efficiency of paint mist and exhaust gas purification, and achieve compact structure and strong applicability , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

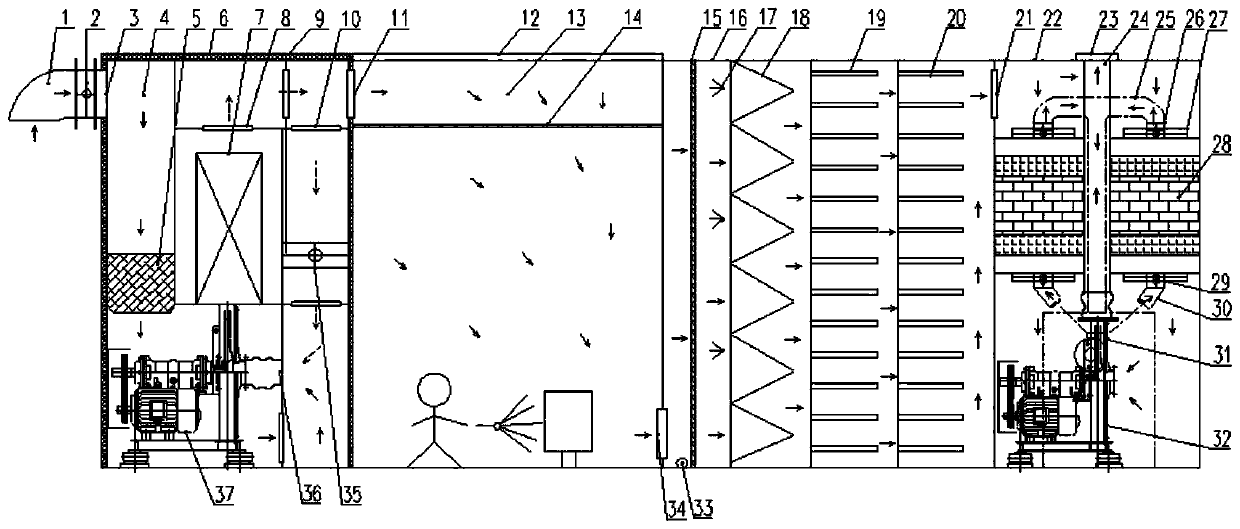

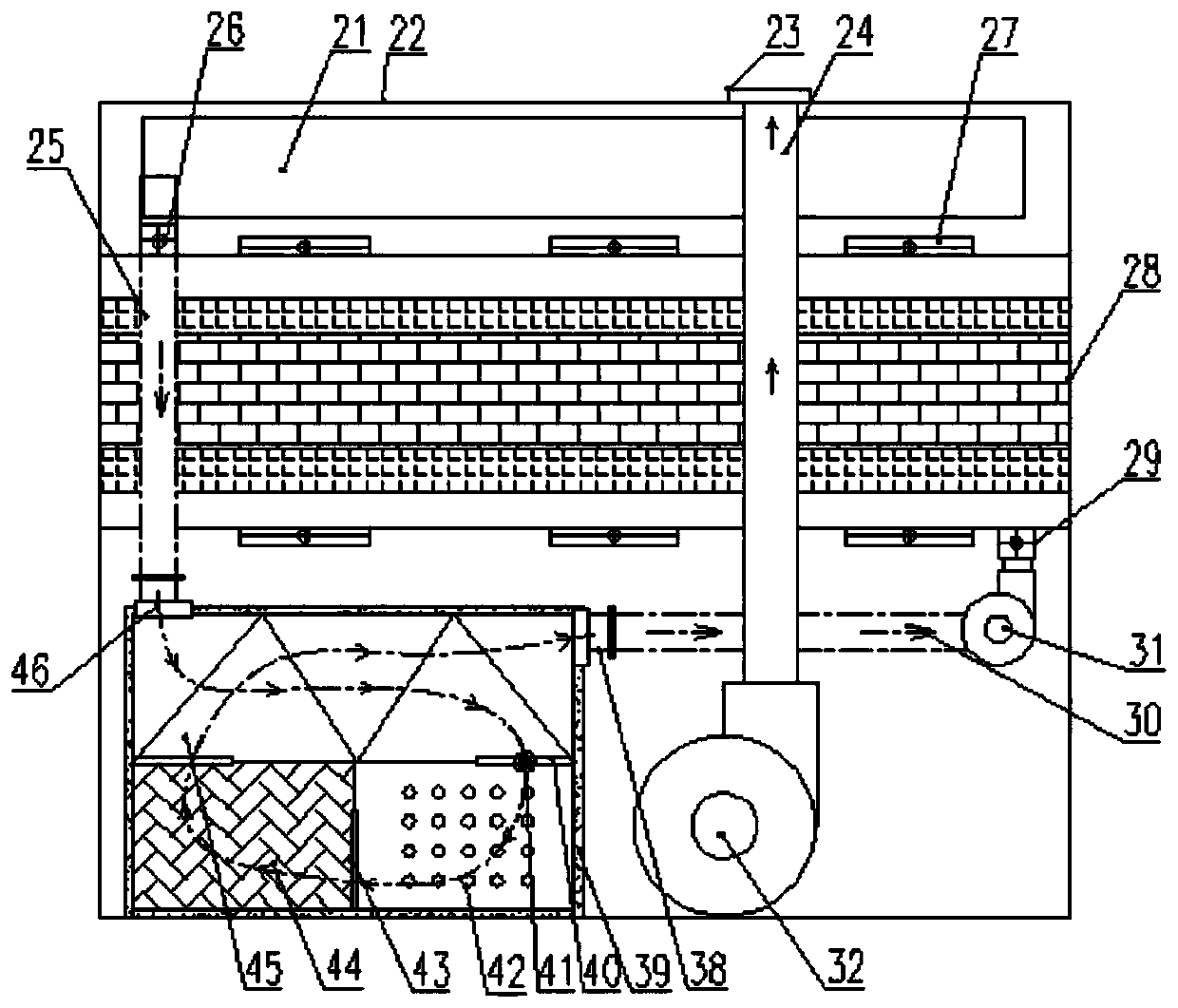

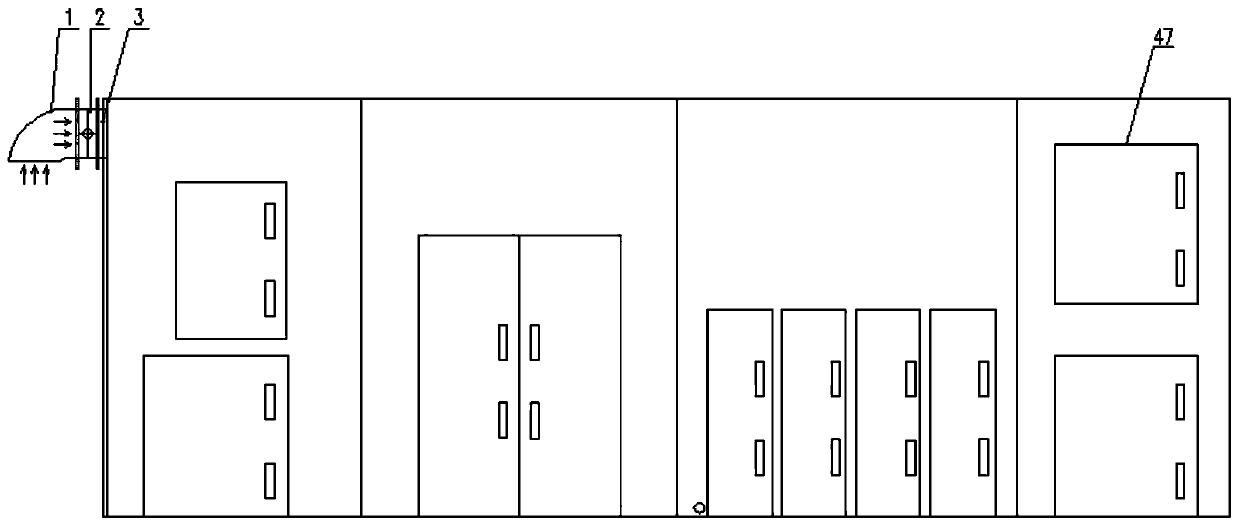

[0032] see figure 1 , the spray drying room in the illustration is an embodiment of the present invention, specifically including an integrally connected fresh air box 6, a spray drying room 12, a paint mist filtering box 16 and an exhaust gas purification box 22, wherein the spray drying room 12 is the painting operation room, the inside of the fresh air box 6 is an integrated structure of the air supply system that provides fresh air and hot air to the spray drying room, the paint mist filter box 16 and the exhaust gas purification box 22 are used to treat the spraying exhaust gas generated by the spray drying room The exhaust gas treatment system is formed into a structure.

[0033] The fresh air box 6 is fixedly connected to one side of the spray drying room 12, and a fresh air inlet 1 is arranged on it, and a fresh air valve 2 is arranged on the fresh air inlet 1, and the fresh air valve 2 forms a fresh air section at the top of one side of the fresh air box 6 Inlet 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com