RV speed reducer cycloidal-pin wheel tool

A technology of cycloid pinwheel and reducer, which is applied in the direction of gear tooth manufacturing equipment, gear teeth, manufacturing tools, etc., which can solve the problems of connection failure, increase of contact stress and transmission error of reducer, pin jam, etc., and achieve reliable clamping Tightening and positioning, improving tooth shape consistency, and improving the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

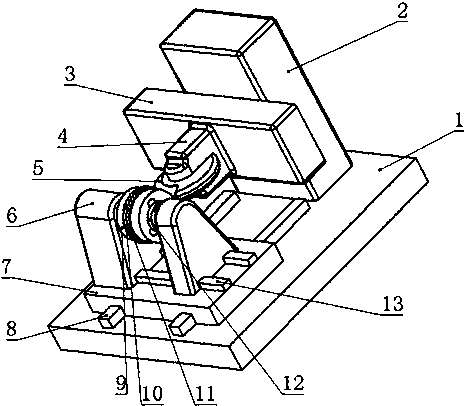

[0023] like figure 1 As shown, this embodiment is a cycloid pin wheel tooling for RV reducer, including a base 1, a fixing mechanism 2, a moving mechanism 3, a grinding wheel installation mechanism 4, a grinding wheel 5, a clamp bracket 6, a support 7, a clamp 9, a cycloid Pin wheel and rotating disc 12, the base 1 is horizontally arranged, the fixing mechanism 2 is vertically fixed on the base 1; the moving mechanism 3 is installed on the fixing mechanism 2 and can move up and down in the vertical direction along the fixing mechanism 3 And move left and right in the vertical direction; the grinding wheel mounting mechanism 4 is installed on the moving mechanism 3, and can swing up and down within the installation range of the grinding wheel mounting mechanism 4; the grinding wheel 5 is installed in the grinding wheel cover of the grinding wheel mounting mechanism 4 and rotates to cut The cycloidal pin wheel; the cycloidal pin wheel includes a cycloidal pin wheel A 10 and a cy...

Embodiment 2

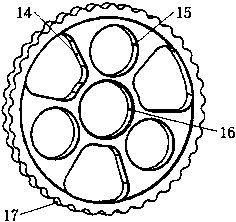

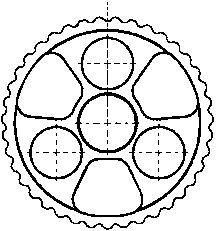

[0031] This embodiment 2 is for the processing method of the RV reducer cycloidal pinwheel tooling described in one item of embodiment 1. The crank bearing through hole of cycloidal pinwheel A and the crank bearing through hole of cycloidal pinwheel B are respectively Align with the round table A of the fixture, and install the needle wheel of the ornament into the fixture; one of the fixtures is fixed, and the other fixture drives the cycloid pinwheel on it to rotate 60° together; the two ends of the fixture bracket move toward each other along the guide rail B, Close until the round table B of one of the fixtures is inserted into the circumferential through hole of the other fixture; the outer teeth of the cycloidal pinwheel A and the cycloidal pinwheel B coincide; the processing method includes the following steps:

[0032] (1) The two ends of the fixture bracket move away from each other along the guide rail B, so that the two ends of the fixture bracket are separated to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com