Full-automatic intelligent metal surface grinding equipment

A metal surface, fully automatic technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of grinding work influence, inconvenient metal plate fixing, easy deviation, etc., to avoid excessive temperature, Improves cleanliness and ensures stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

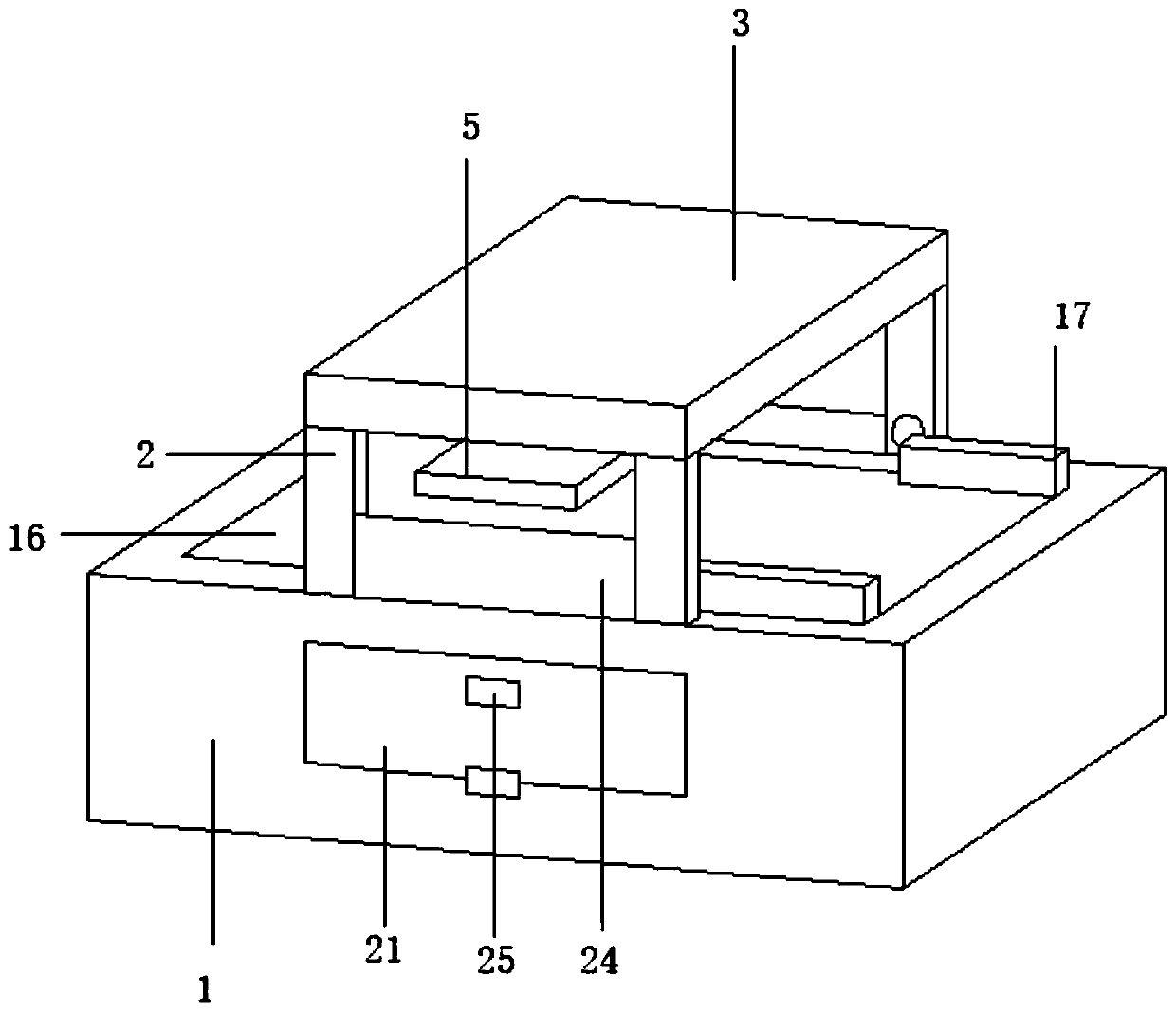

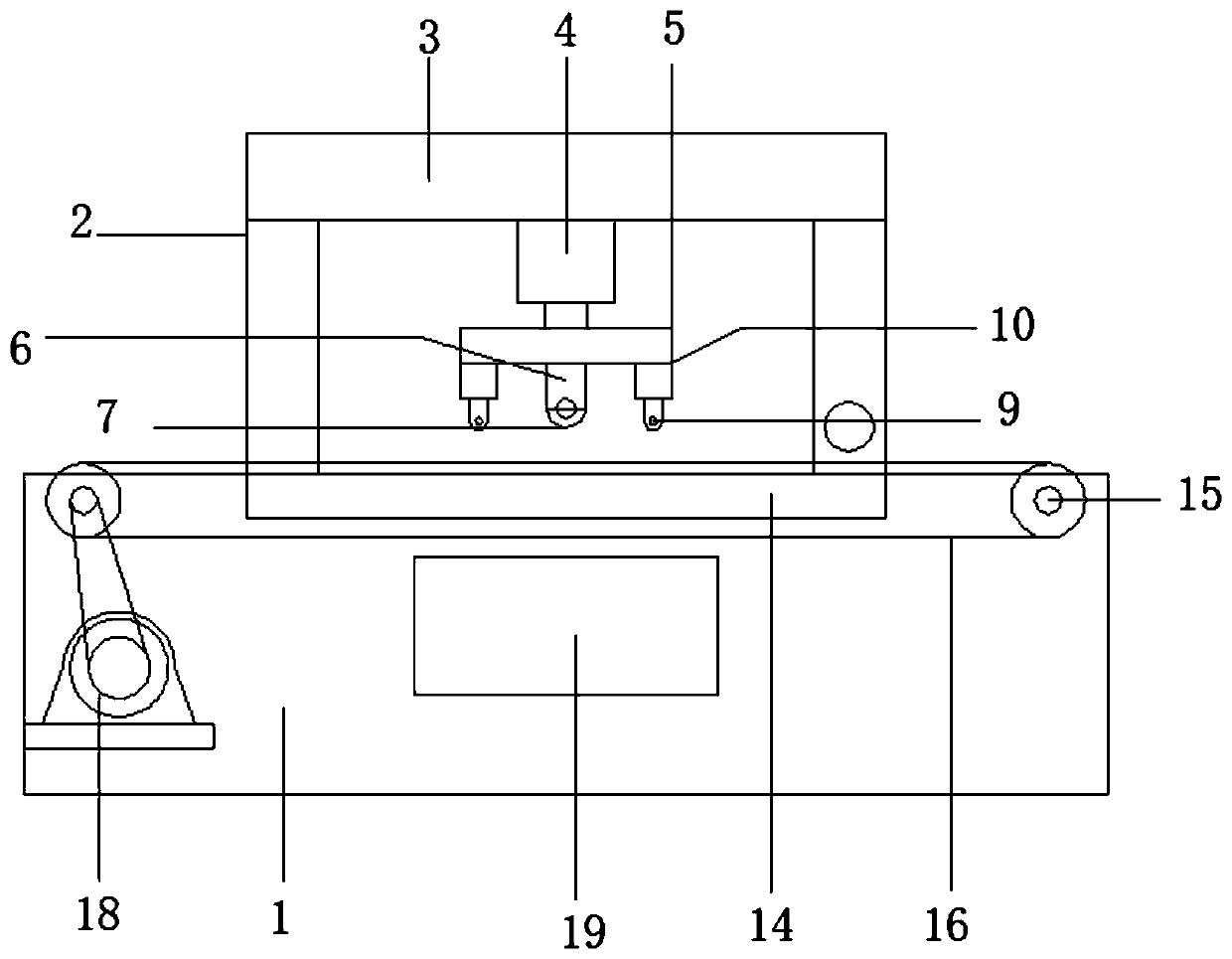

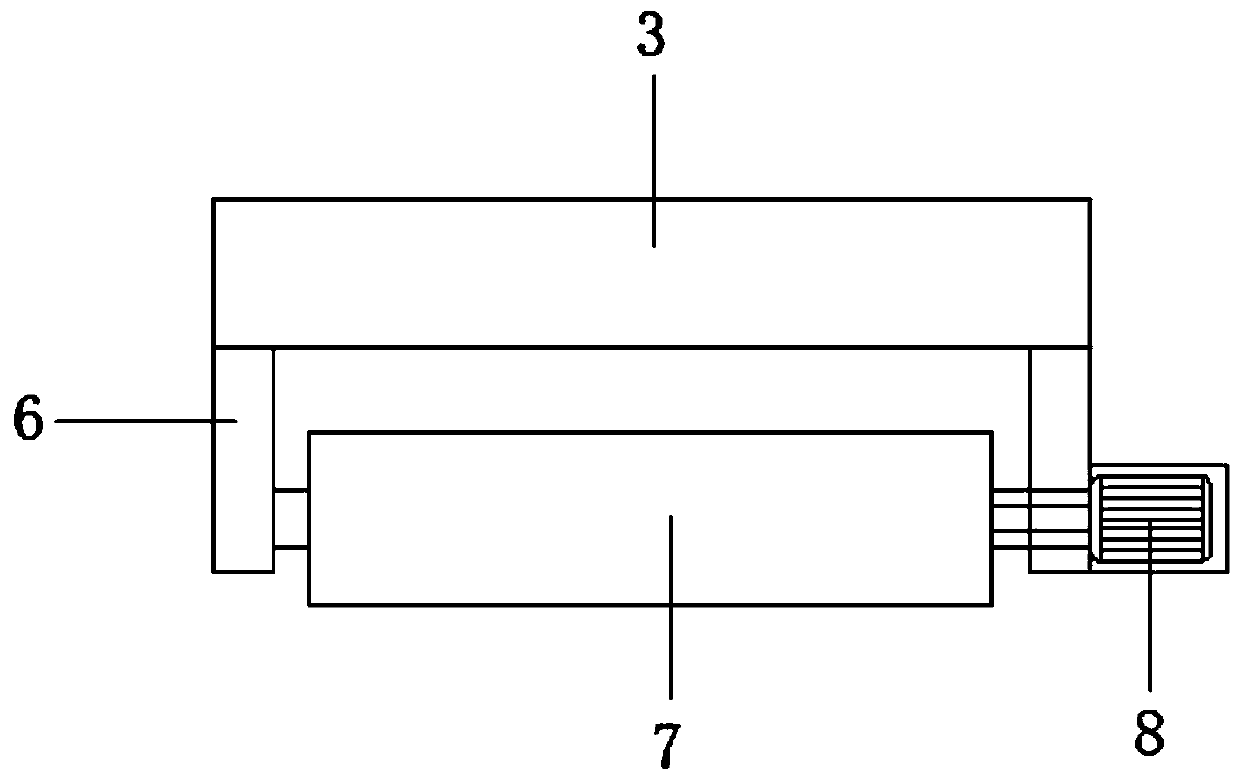

Embodiment 1

[0022] see Figure 1-Figure 6 , the present invention provides a technical solution: a fully automatic intelligent metal surface grinding equipment, including a fixed table 1, the top of the fixed table 1 is fixed with a fixed rod 2, and the top of the fixed rod 2 is fixed with a fixed plate 3, The bottom of the fixed plate 3 is symmetrically fixed with an electric telescopic rod 4, which realizes the movement of the grinding roller 7 up and down. , between the connecting rods 6, a grinding roller 7 is arranged, and one end of the grinding roller 7 is fixedly connected with a grinding motor 8, and the grinding motor 8 drives the grinding roller 7 to rotate so as to grind the metal surface, and the grinding roller 7 Fixed rollers 9 are arranged on both sides, and the fixed rollers 9 are fixedly installed on the bottom of the lifting plate 5 through a compression rod 10. The compression rod 10 includes a fixed sleeve rod 11, a compression spring 12, and a compression pole 13. T...

Embodiment 2

[0025] Such as figure 2 As shown, the servo motor 18 is fixedly installed in the inner cavity of the fixed platform 1 through a shock absorber, the output shaft of the servo motor 18 is fixedly provided with a driving pulley, and one side of the roller shaft 15 is fixedly provided with a driven pulley , and the driving pulley and the driven pulley are connected by belt transmission, and the roller shaft 15 is driven to rotate by the servo motor 18, so that the conveyor belt 16 rotates, thereby realizing the purpose of conveying the metal through the conveyor belt 16.

Embodiment 3

[0027] Such as Figure 6 As shown, the surface of the inner cavity of the storage tank 19 is provided with a slide rail, and the bottom of the dust collection box 21 is provided with a pulley corresponding to the slide rail, and one side of the fixed table 1 is connected to the dust collection box 21 through a lock. , so that the dust box 21 is convenient to enter and exit the storage tank 19, thereby making it convenient for people to process the waste in the dust box 21.

[0028]The working principle of the present invention: when in use, put the metal plate to be processed on the fixed table 1, start the servo motor 18 to rotate the conveyor belt 16, thereby transporting the metal to the workbench 14, and let the lifting plate 5 through the electric telescopic rod 4 Descending, because the fixed roller 9 is lower than the grinding roller 7, the fixed roller 9 will contact the metal first, and the lifting plate 5 continues to descend. When the grinding roller 7 contacts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com