Preparation method for PEEK with topological pattern on surface

A topology and pattern technology, applied in the field of PEEK preparation, can solve the problems of PEEK surface melting, difficult to maintain regular patterns, unable to meet the pattern requirements of sub-micron scale, etc., to increase the cell adhesion rate and topological morphology The effect of controllable and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing PEEK with a topological pattern on the surface, and the steps are as follows:

[0049] (1) Using photolithography combined with ICP, a topological pattern is prepared on the surface of a titanium substrate to obtain a template with a topological pattern on the surface;

[0050] (2) Put the PEEK powder on the template with the topological pattern on the surface obtained in step (1), cold press for 3 minutes at a temperature of 22°C and a pressure of 100 MPa, and press the PEEK powder into a shape while making the template The topological pattern is transferred to the pressed PEEK surface;

[0051] (3) Separate the template from the pressed PEEK by mechanical force to obtain a PEEK with a topological pattern on the surface.

[0052] According to GB / T 22315-2008 (Test Method for Modulus of Elasticity and Poisson's Ratio of Metallic Materials), the elastic modulus of PEEK provided in this embodiment is measured to be 422.6 MPa, which ...

Embodiment 2

[0054] This embodiment provides a method for preparing PEEK with a topological pattern on the surface. The difference from embodiment 1 is that the cold pressing pressure in step (2) is 400 MPa.

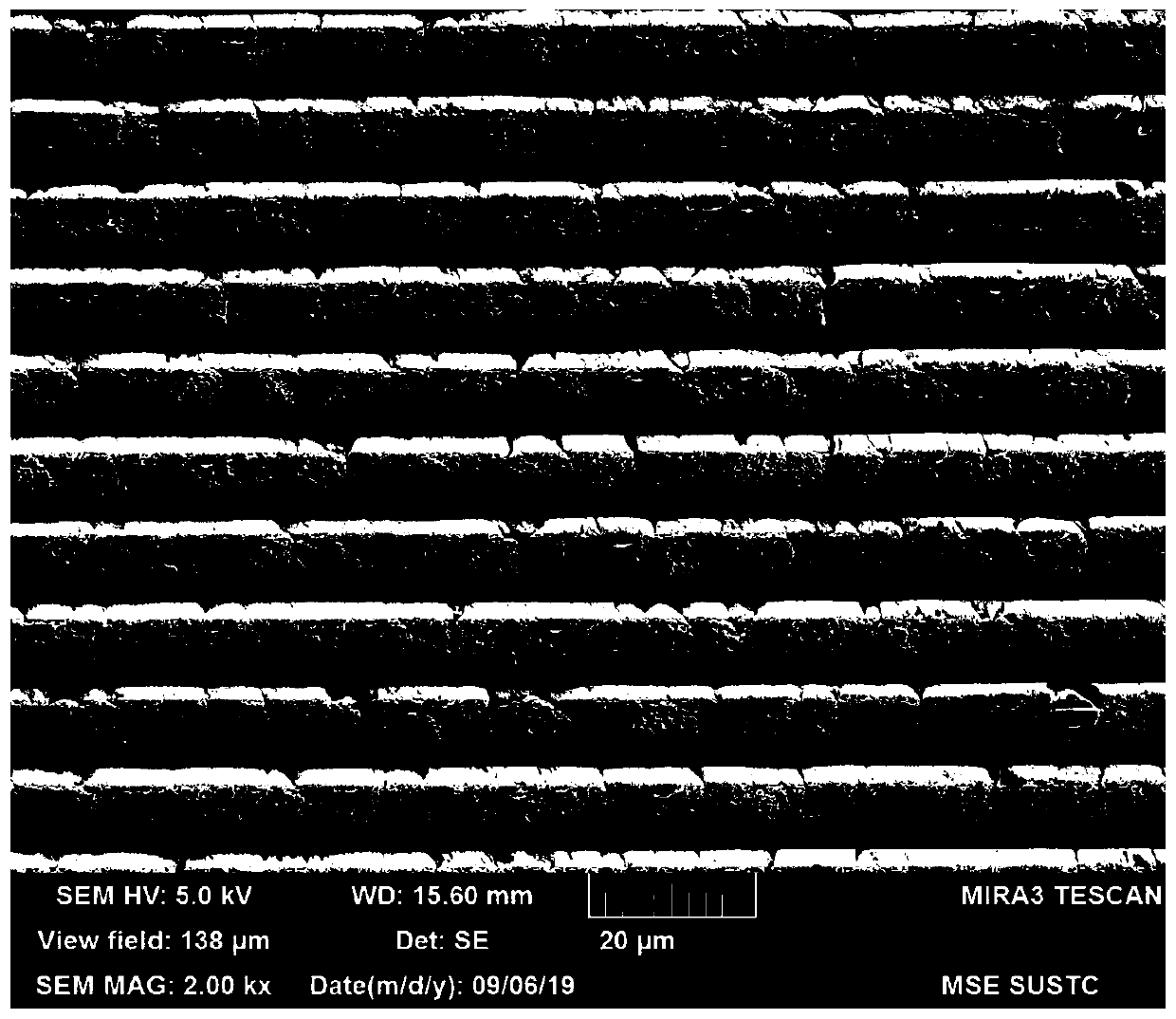

[0055] According to GB / T 22315-2008 (Test method for elastic modulus and Poisson's ratio of metallic materials), the elastic modulus of PEEK provided in this embodiment is measured to be 633.7 MPa, which conforms to the range of human cancellous bone modulus. Using a scanning electron microscope to observe the surface morphology of the PEEK provided in this example, the results are as follows figure 2 Shown. by figure 2 It can be seen that the topological structure of the PEEK surface provided by this embodiment is clear, and its structure is denser than that of Embodiment 1.

Embodiment 3

[0057] This embodiment provides a method for preparing PEEK with a topological pattern on the surface. The difference from Embodiment 1 is that the cold pressing pressure in step (2) is 600 MPa and the topological pattern is different.

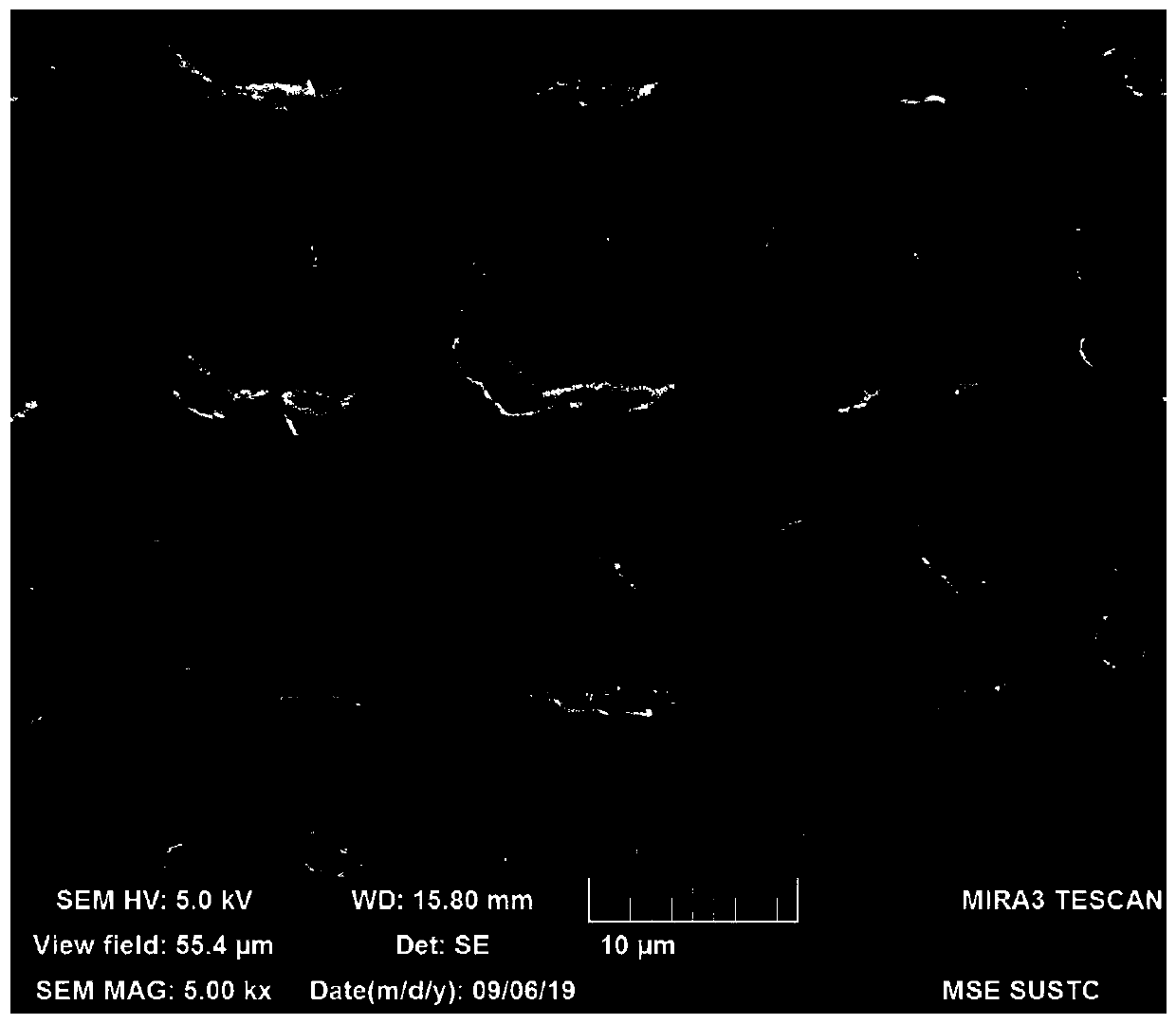

[0058] According to GB / T 22315-2008 (Test method for elastic modulus and Poisson's ratio of metallic materials), the elastic modulus of PEEK provided in this embodiment is measured to be 633.12 MPa, which is in line with the range of human cancellous bone modulus. Using a scanning electron microscope to observe the surface morphology of the PEEK provided in this example, the results are as follows image 3 Shown. by image 3 It can be seen that the topological structure of the PEEK surface provided by this embodiment is clear, and its structure is denser than that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com