Targeted induction and directional energy composite three-dimensional forming device and method

A technology of three-dimensional shaping and targeting induction, which is applied in coating devices, manufacturing auxiliary devices, additive manufacturing, etc., to achieve the effects of reducing equipment costs, increasing interlayer bonding strength and tissue uniformity, and improving directional energy absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

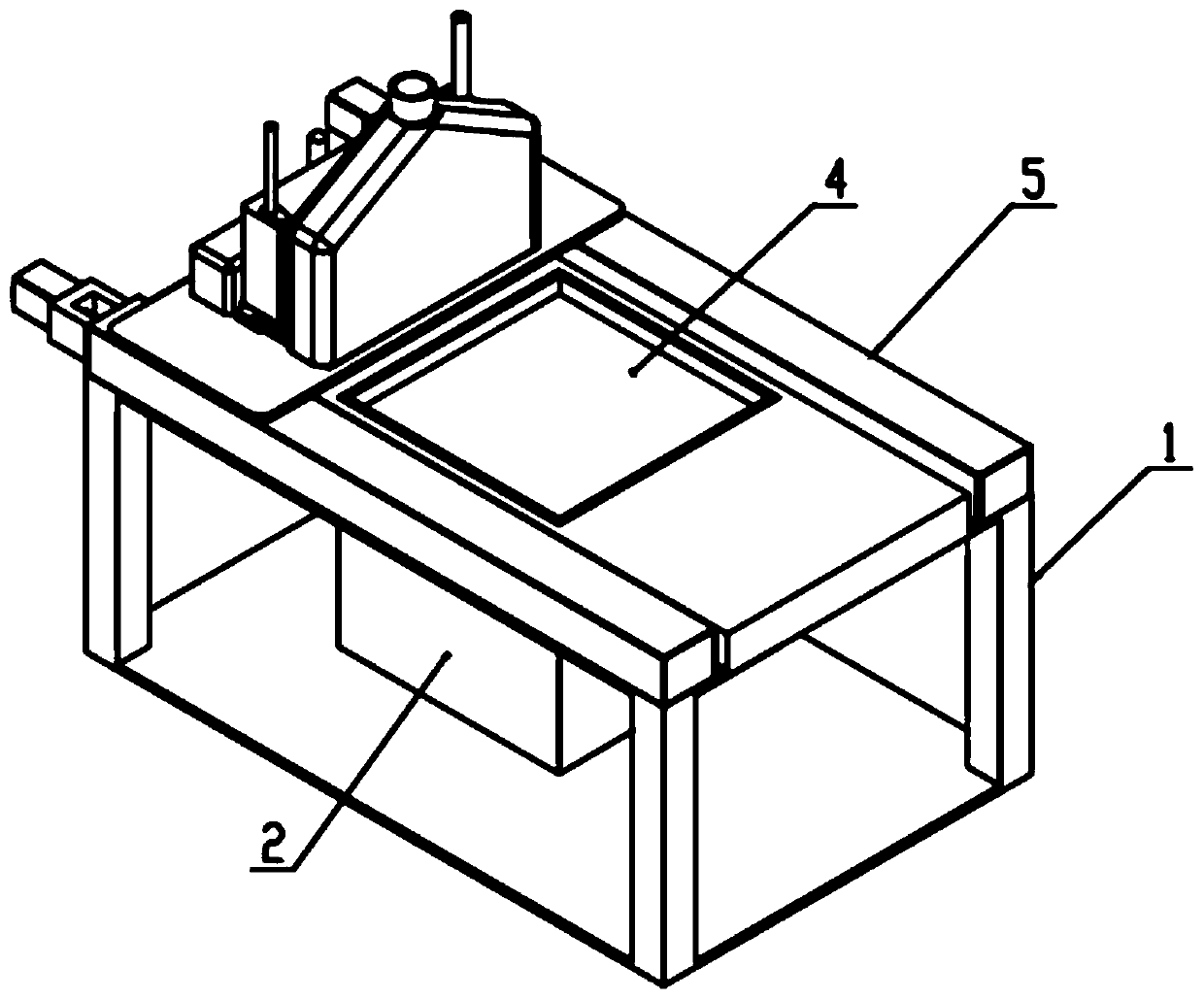

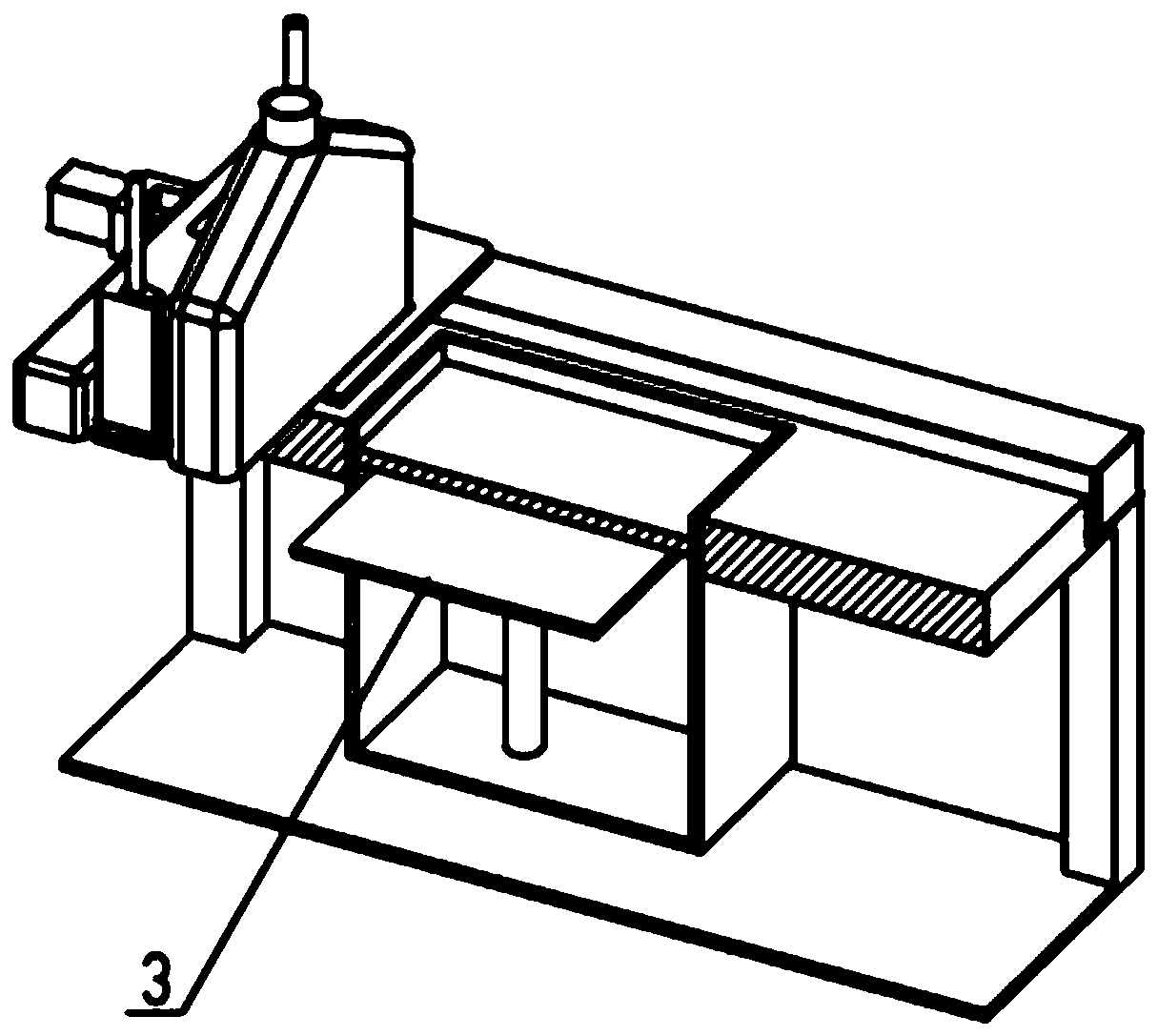

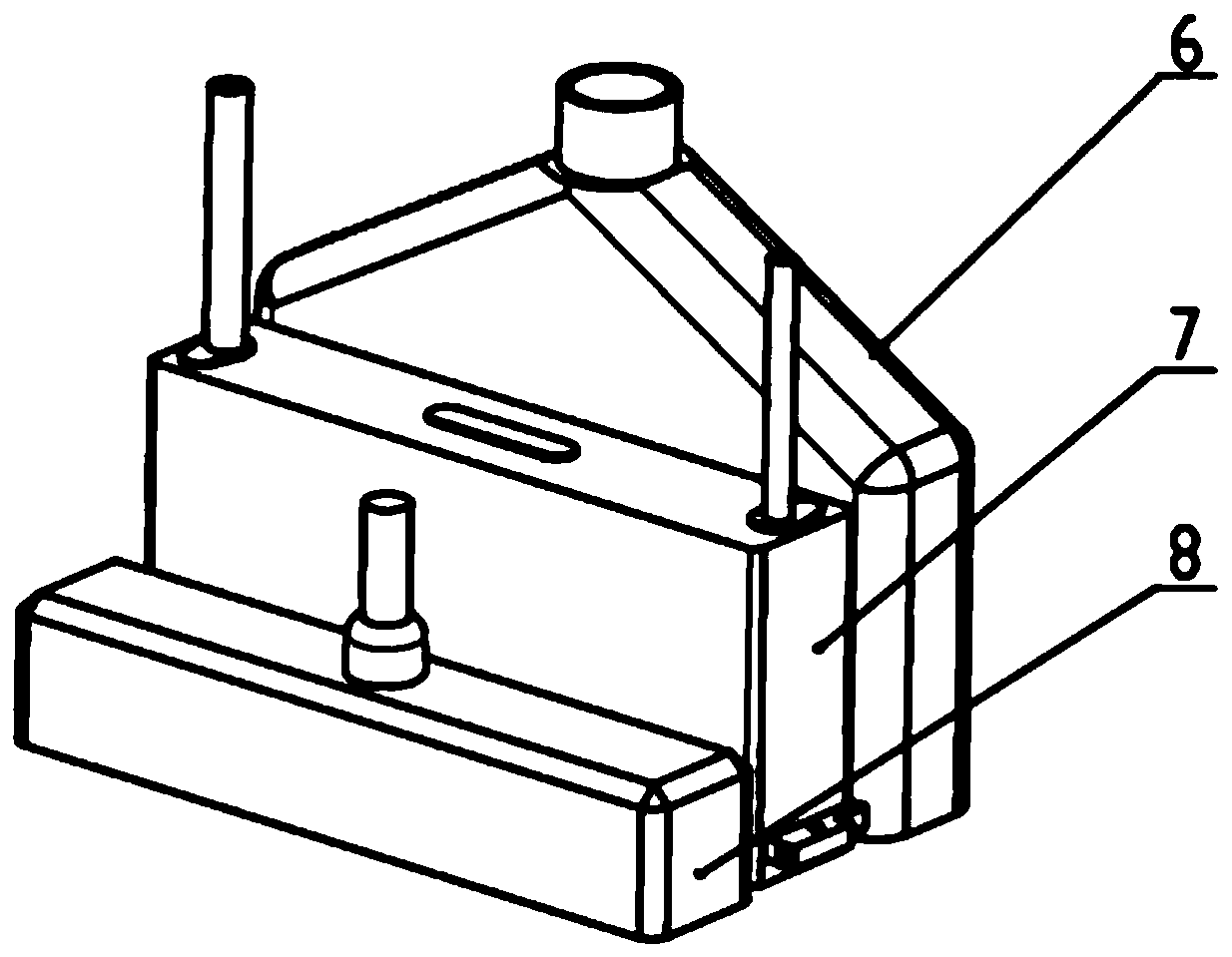

[0023] A target induction and directed energy composite three-dimensional forming device, such as Figure 1-3 As shown, there is a forming groove 2 on the rigid frame 1. There is a lifting platform 3 inside the forming groove 2. There is a forming substrate 4 on the top of the lifting platform 3. The edge of the forming substrate 4 slides and seals with the inner wall of the forming groove 2. The lifting platform 3 can drive the forming substrate. 4 Move up and down and position in the forming tank 2; there is a linear module 5 on the rigid frame 1, and a liquid / powder spreading component 6, an inducer injection component 7, and a directed energy scanning component 8 are mounted on the moving platform of the linear module 5; The module 5 drives the liquid / powder spreading assembly 6, the inducer spraying assembly 7, and the directed energy scanning assembly 8 to translate over the opening of the forming groove 2, so that the liquid / powder spreading assembly 6 can spread the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com