Iron protein succinate and method for industrially preparing iron protein succinate

A technology of iron protein succinate and protein, applied in the field of medicine, can solve the problems of unstable quality, high cost of freeze-drying process, uneven color of products, etc., and achieves the effects of simple production process, reduced production cost and good iron load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment is an exemplary method for preparing iron protein succinate, which comprises the following steps:

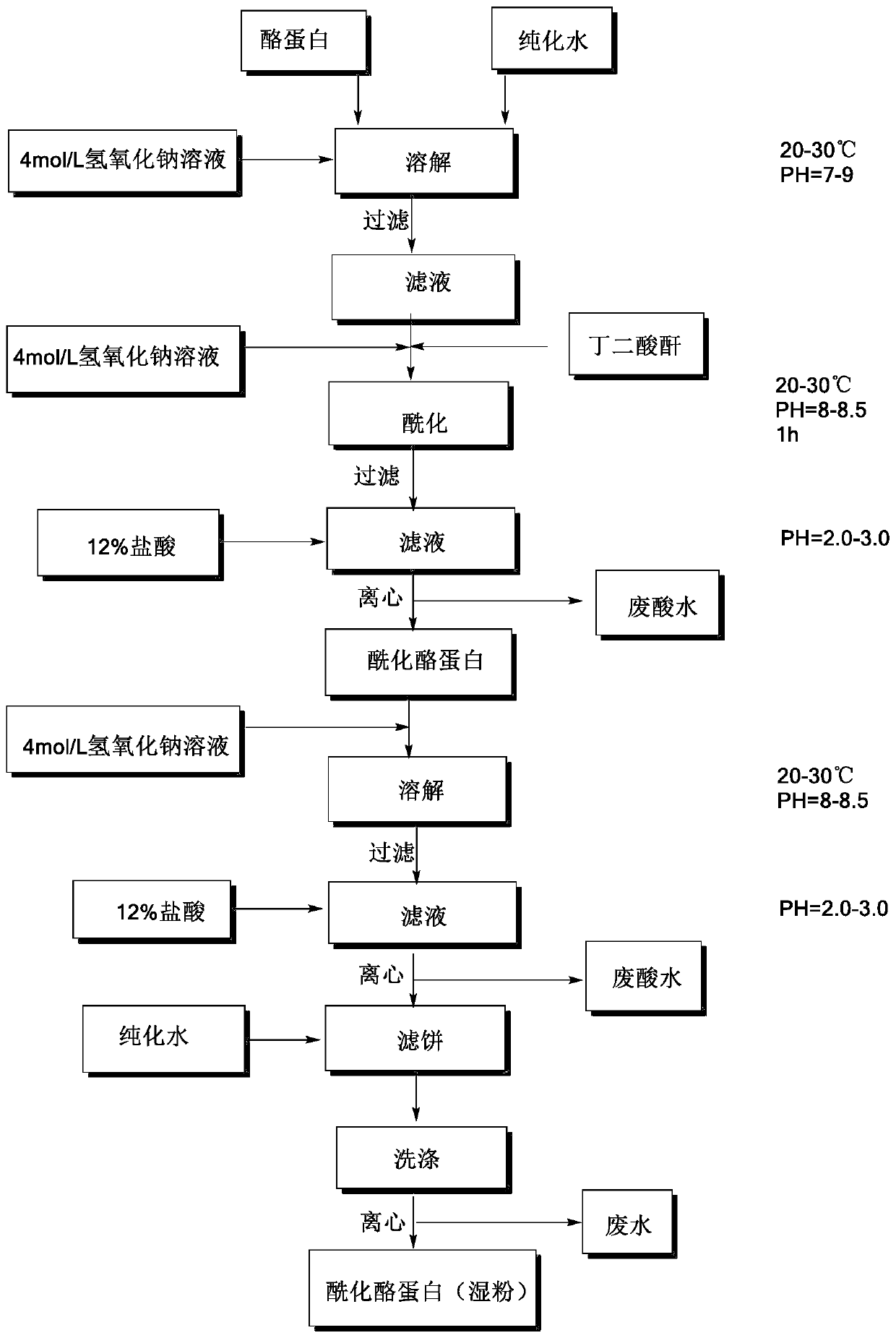

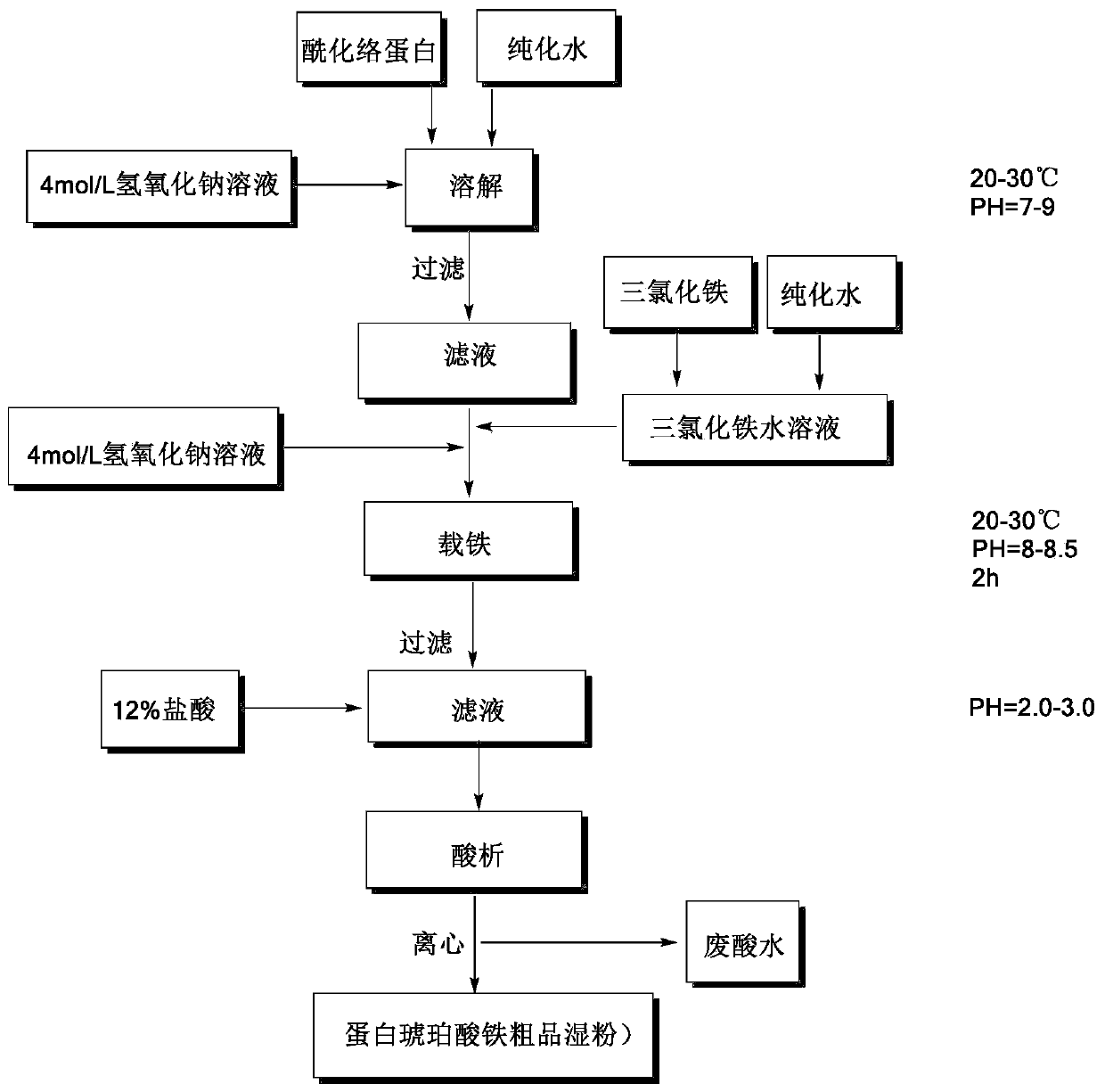

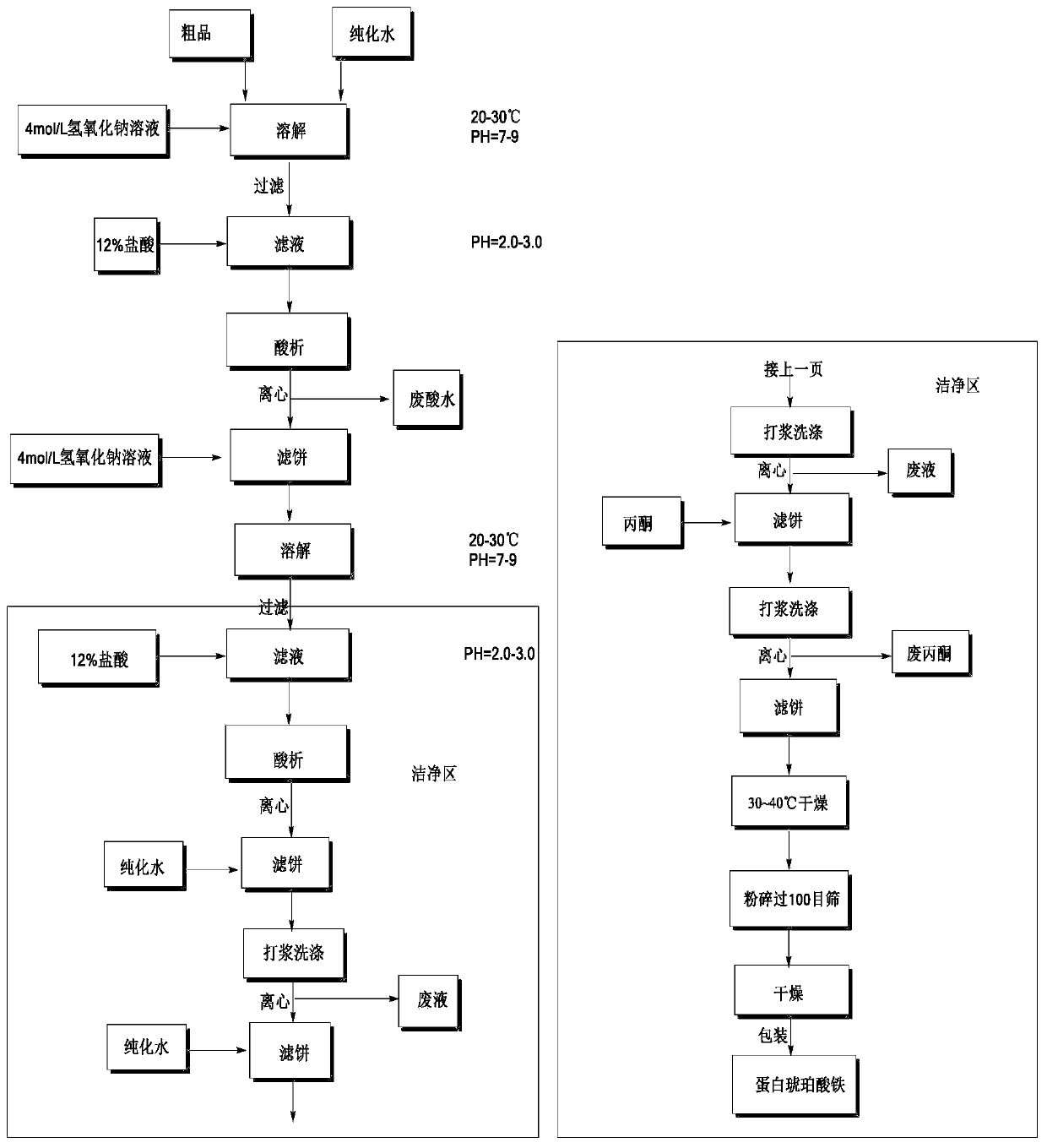

[0055] Such as figure 1 As shown in the acylation step, add 600kg of purified water to a clean 1000L reactor, start stirring, slowly add 40.0kg of casein, stir evenly, add dropwise 4mol / L sodium hydroxide solution, adjust the pH value to 7.0-9.0, so that The casein is dissolved and filtered. The filtrate was placed in another clean 1000L reaction kettle, and 16.0kg (0.4 equivalent) of succinic anhydride was slowly added in several times under temperature control at 20-30°C, and 4mol / L sodium hydroxide solution was added dropwise to maintain the pH of the reaction system at 8.0 -8.5, continue to stir for 1.0h after the addition, and filter. The filtrate was placed in a clean 1000L reaction kettle, and 12% hydrochloric acid solution was added dropwise under stirring condition to adjust the pH value at 2.0-2.5 to precipitate...

Embodiment 2

[0076] Except that the acetone of step 5) in the preparation method of embodiment 1 is ethanol, other specific preparation steps are identical with embodiment 1. The results of the determination of iron protein succinate prepared in this example are shown in Table 2.

[0077] Table 2 - Determination of iron protein succinate

[0078]

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com