Stimuli-responsive polymer grafted wrinkled intelligent surface, and preparation method and application thereof

A stimuli-responsive, high-molecular technology, applied in the direction of coating, etc., can solve the problems of complex process, poor controllability, single structure, etc., and achieve the effect of directional transmission, enhanced performance switching range, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The invention provides a method for preparing a wrinkled smart surface grafted with a stimuli-responsive polymer, which comprises the following steps:

[0062] S1. Grafting a stimuli-responsive polymer onto the surface of a sample with a wrinkled structure.

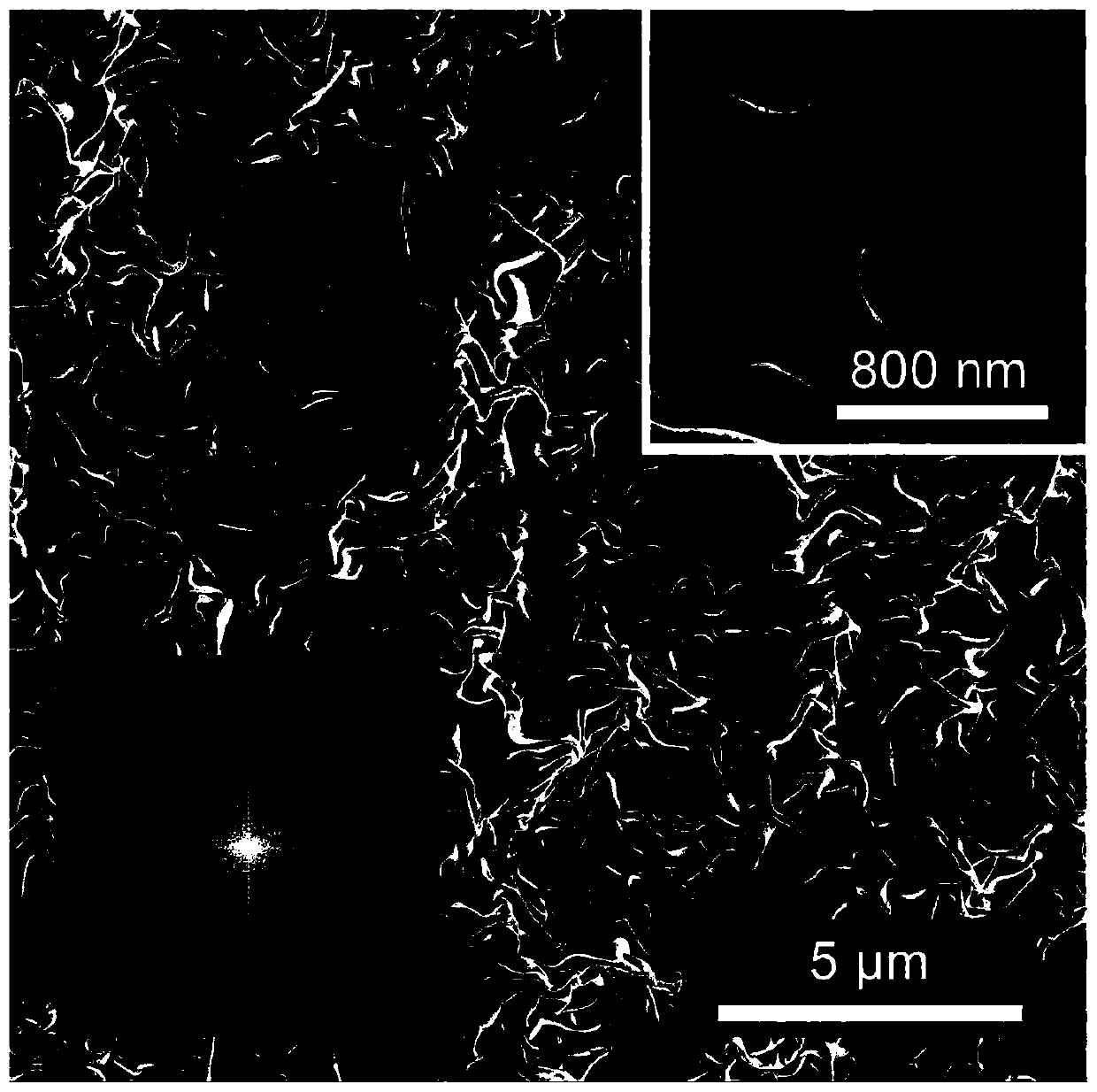

[0063] In this application, the stimuli-responsive polymer is grafted onto the wrinkled structure by selecting a stimuli-responsive polymer with a specific functional group to coordinate with the wrinkled structure with a specific metal film. The wrinkled structure has a large surface roughness, and the performance switching range of the smart surface can be enhanced by grafting stimuli-responsive polymers on its surface.

[0064] Wherein, the metal film is Au, Ag, Al, Sn or Ti; the functional group is mercapto or amine; preferably, the metal film is Au, and the functional group is mercapto.

[0065] Next, in this application, the preparation of a stimuli-responsive polymer with a thiol-terminated polymer and a wr...

Embodiment 1

[0088] This embodiment provides a stimuli-responsive polymer grafted wrinkled smart surface (PDEAEMA-Au / PS wrinkled surface), which has switchable surface wettability, and its preparation method includes:

[0089] S101. Prepare a stimuli-responsive polymer with stimuli responsiveness.

[0090] Deoxygenate the reaction system first, add 5.91g of monomer (DEAEMA), 0.013g of initiator (AIBN) and 0.089g of chain transfer agent (CPADB) into 30mL of tetrahydrofuran, block oxygen at 70°C and stir for 6h.

[0091] After the polymerization reaction was completed, the reaction solution was precipitated in 250 mL of n-hexane, and then the precipitate was filtered out and purified in vacuum. The crude product was 3.12 g of a polymer with a dithioester end group.

[0092] Then, 3.12 g of the crude product, 0.494 g of hexylamine and 8.30 mg of dithiothreitol (DTT) were added into 30 mL of dichloromethane, and the reaction was stirred for 12 h at room temperature with oxygen isolated. Afte...

Embodiment 2

[0100] This example provides a stimuli-responsive polymer grafted wrinkled smart surface (PDEAEMA-Au / PS wrinkled surface), the preparation method of which is basically the same as that of Example 1, the difference is that in step S102 of this example, in PS The sputtering time of the Au thin film on the surface of the heat-shrinkable sheet was changed to 50s. Under this condition, the thickness of the Au film was about 5.5nm; correspondingly, the obtained wrinkled surface was as follows image 3 As shown, the wrinkle period is about 130 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com