Continuous processing method for durable yellowing-resistant high-whiteness cotton type fabric

A processing method and anti-yellowing technology, which is applied in dyeing, textiles and papermaking, etc., can solve the problem that the anti-phenol yellowing effect of cotton fabrics cannot meet the requirements of level 4, cannot be completely solved, and whiteness improvement has no effect, etc. Problems, to achieve the effect of improving wearing performance, good promotion prospects, and improving wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

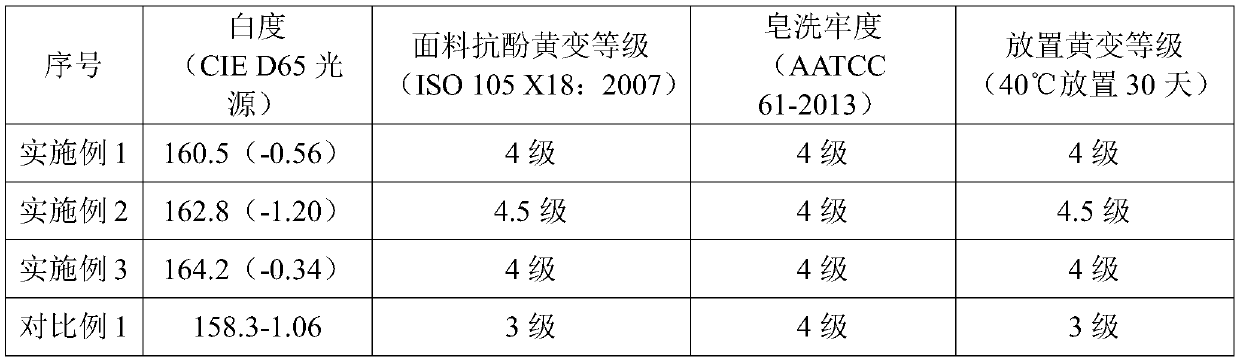

Examples

Embodiment 1

[0032] Weave specification: CPT70*NYLON40D*240*130*51 / 53, weave pattern: 4 / 1 satin.

[0033] The long-lasting anti-yellowing high white cotton type fabric continuous processing method described in the present embodiment 1 comprises the following steps:

[0034] (1) Conventional fabric pretreatment

[0035] The cotton / nylon gray fabric is sequentially subjected to singeing → desizing → scouring → bleaching → mercerizing to obtain a semi-finished pure cotton fabric.

[0036] (2) Padding and whitening finishing solution

[0037] The whitening finishing solution is composed of the following concentrations of components: brightening agent A: 12g / L, brightening agent B: 1.5g / L, anti-yellowing agent 20g / L, and the components of the above materials are fully dissolved in water And mix evenly; Cotton / nylon fabric is pad-rolled in above-mentioned whitening finishing solution, and the excess rate of fabric is 63%.

[0038] The brightener A is a 1,2-stilbene derivative brightener produ...

Embodiment 2

[0046] Weave specification: CPT60*CPT60*160*110*58 / 59, weave pattern: plain weave.

[0047] The long-lasting anti-yellowing high white cotton type fabric continuous processing method described in present embodiment 2 comprises the following steps:

[0048] (1) Conventional fabric pretreatment

[0049] The pure cotton fabric is sequentially subjected to singeing→desizing→scouring→bleaching→mercerizing to obtain semi-finished pure cotton fabrics.

[0050] (2) Padding and whitening finishing solution

[0051] The whitening finishing solution is composed of the following concentrations of ingredients: whitening agent A 9g / L, whitening agent B 4g / L, anti-yellowing agent 20g / L, and the components of the above materials are fully dissolved in water and mixed uniformly; The pure cotton gray cloth is padded in the above-mentioned whitening finishing solution, and the fabric scrapping rate is 62%.

[0052] The brightener A is a 1,2-stilbene derivative brightener produced by Archroma ...

Embodiment 3

[0060] Weave specification: CM30*NYLON200D*170*80*55 / 56, weave pattern: 3 / 1 twill.

[0061] The long-lasting anti-yellowing high white cotton type fabric continuous processing method described in present embodiment 3 comprises the following steps:

[0062] (1) Conventional fabric pretreatment

[0063] The cotton / nylon gray fabric is sequentially subjected to singeing → desizing → scouring → bleaching → mercerizing to obtain a semi-finished pure cotton fabric.

[0064] (2) Padding and whitening finishing solution

[0065] The whitening finishing solution is composed of the following concentrations of ingredients: whitening agent A 2.5g / L, whitening agent B 10g / L, anti-yellowing agent 25g / L, fully dissolve the components of the above materials in water and mix them uniformly ; Cotton / nylon fabric is pad-rolled in the above-mentioned whitening finishing solution, and the excess rate of the fabric is 65%.

[0066] The brightener A is a 1,2-stilbene derivative brightener produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com