Intelligent sensing system for water stop performance of rubber sealing gaskets of subsurface structure joints

A rubber gasket and underground structure technology, applied in underwater structures, signal transmission systems, infrastructure engineering, etc., can solve the problem of affecting the working performance of the gasket, the inability to apply the force monitoring of the tunnel rubber gasket, and the difficulty of automatic displacement monitoring Monitoring and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

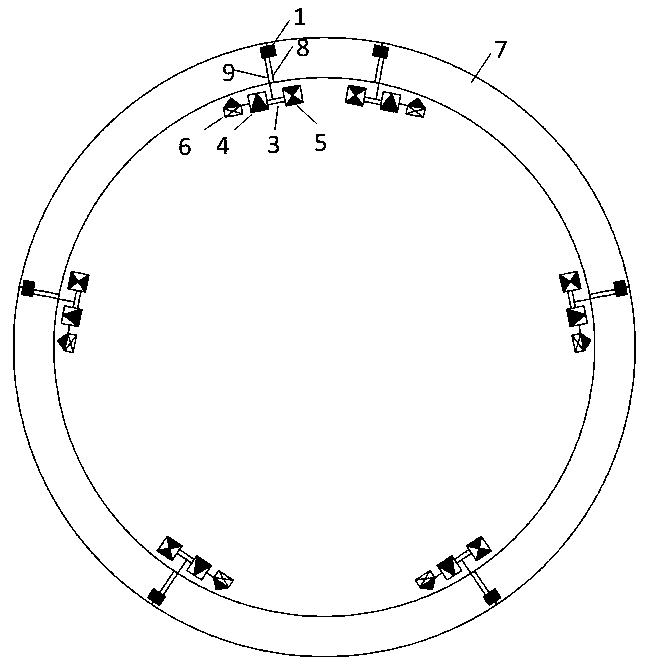

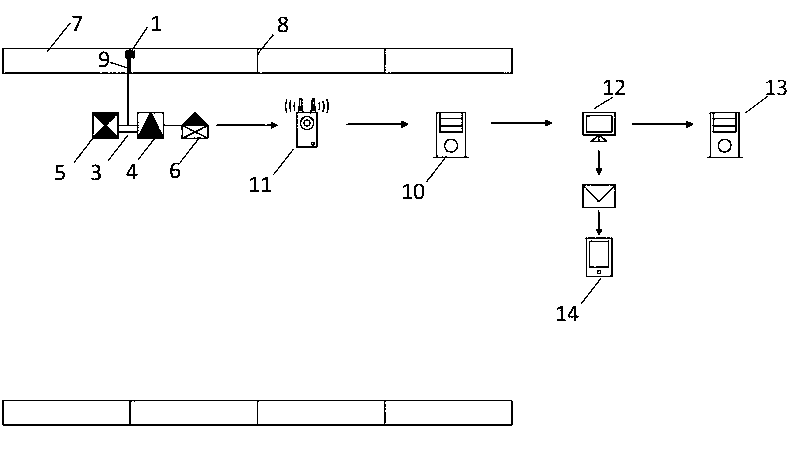

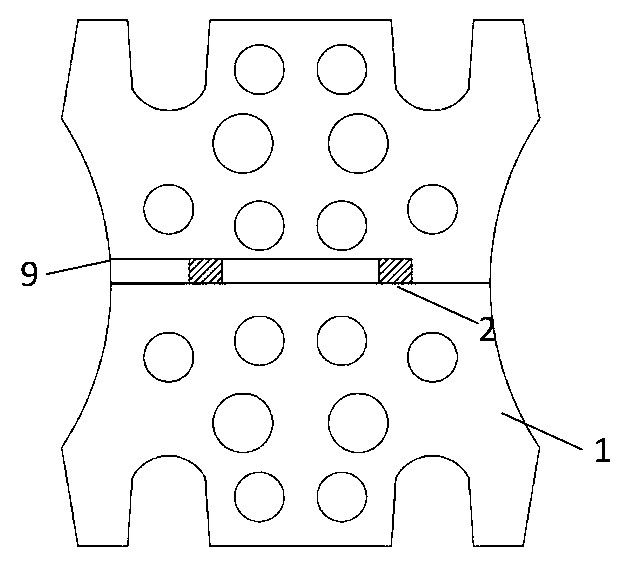

[0037] The waterproof performance intelligent perception system of the underground structure joint rubber gasket in this embodiment is as follows: figure 1As shown, the piezoelectric rubber sensing component 2 is arranged in the rubber gasket 1 of the underground structure joint 8 of the underground structure prefabricated part 7, and the piezoelectric rubber sensing component 2, data line 3, and intelligent control are connected through the lead hole 9. Device 4 and wireless data transmitter 6 form a piezoelectric rubber sensor; the piezoelectric rubber sensor 2, data line 3, intelligent controller 4 and energy storage 5 form a vibration energy harvester; the piezoelectric rubber sensor is connected in series with the vibration energy harvester connect.

[0038] Such as figure 2 As shown, the above piezoelectric rubber sensor, gateway 10, repeater 11, data collection server 12, database server 13 and user terminal 14 form an intelligent sensing system.

[0039] Such as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com