Magnetic coupling driving numerical control plug

A plug, magnetic coupling technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of complex dynamic sealing structure and processing cost, high flow control accuracy, high pressure at the valve outlet, etc. , to achieve the effect of improving system reliability, high flow control accuracy, and reducing sealing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

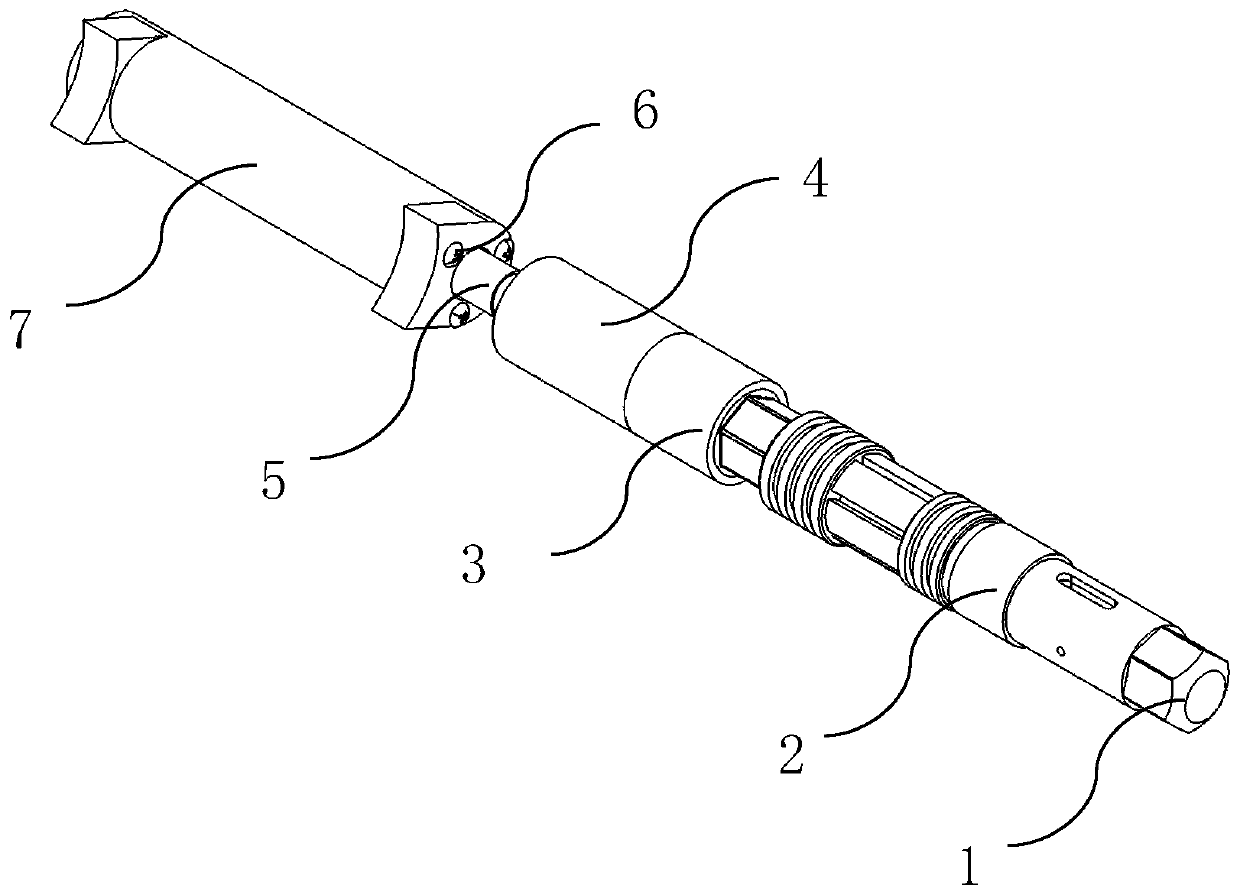

[0018] figure 1 As shown, the magnetic coupling transmission numerical control plug includes a numerical control plug body 2, a lower plug 1, a titanium alloy plug 3, a permanent magnet fixing sleeve 4, a coupling 5, a cross recessed countersunk head screw 6 and a high Torque DC Motor Housing7.

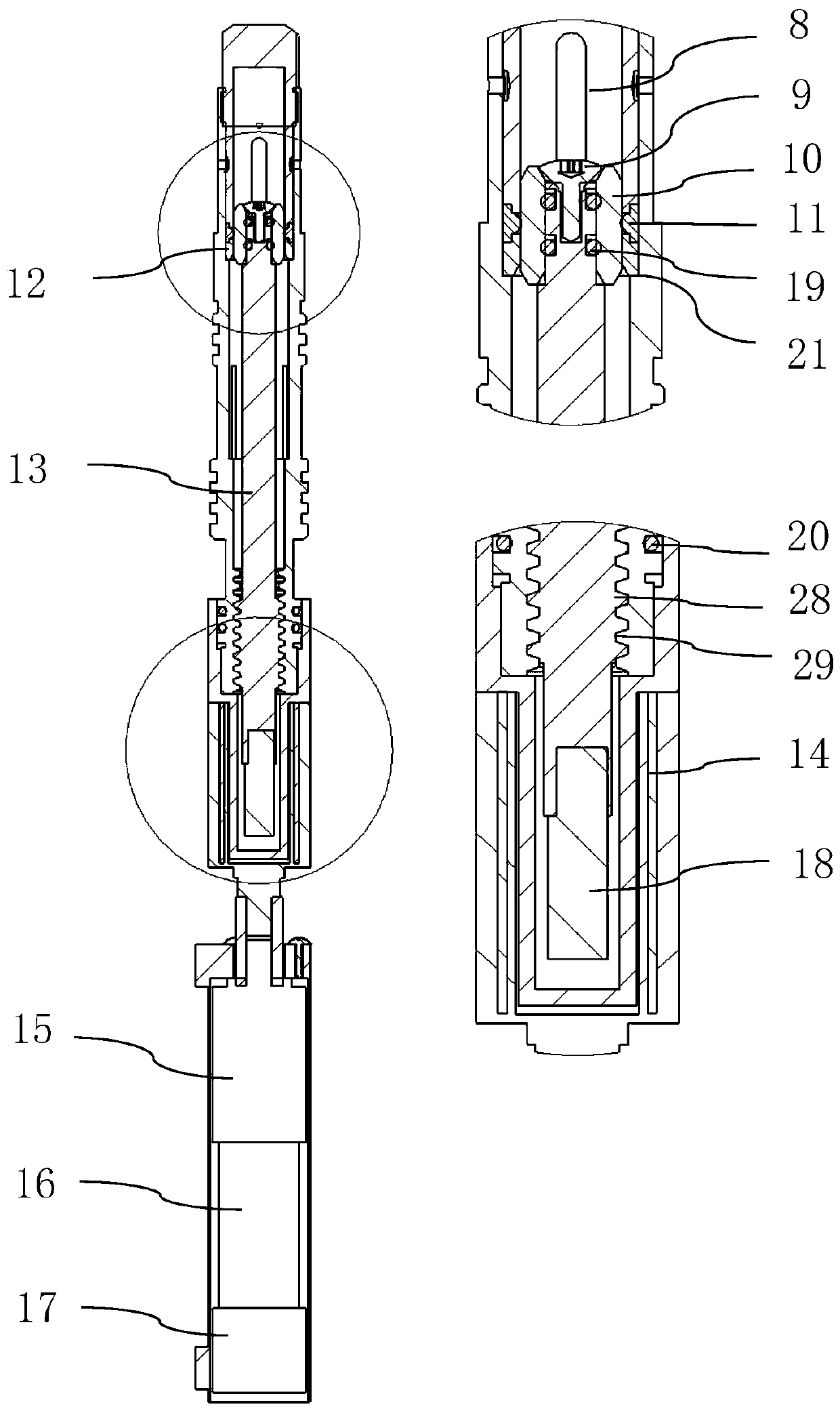

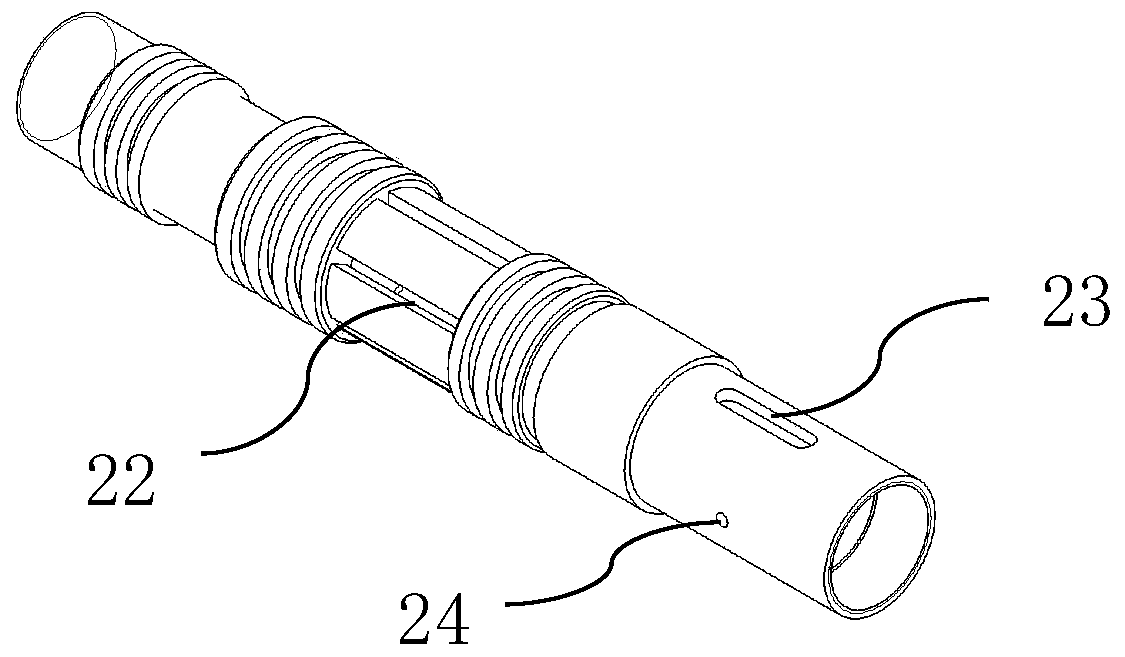

[0019] figure 2 Shown is the overall cross-sectional view and partial enlarged view of the magnetic coupling transmission digital control plug of the present invention. Depend on figure 2 It can be seen that the valve sleeve 8, the hexagonal socket head screw 9, the valve core 10, the rubber ring 11, the metal retaining ring 12, the transmission shaft 13, the permanent magnet piece 14, the reducer 15, the high torque DC motor 16, the absolute value encoder 17. The permanent magnet shaft 18, the first O-ring set 19, the second O-ring set 20, the positioning shoulder 21, the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com