A tailings dry mining method based on groundwater drainage in a valley-type tailings pond

A tailings pond and groundwater technology, applied in underground mining, drainage, ground mining, etc., can solve problems such as strict use conditions, high labor production efficiency, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

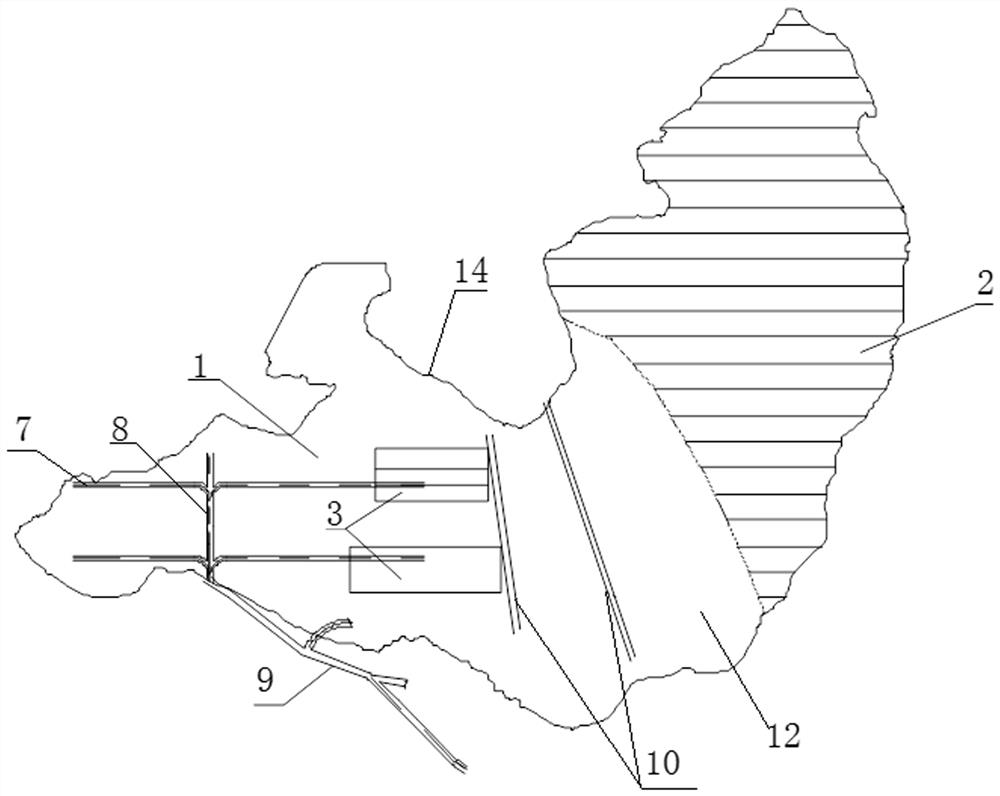

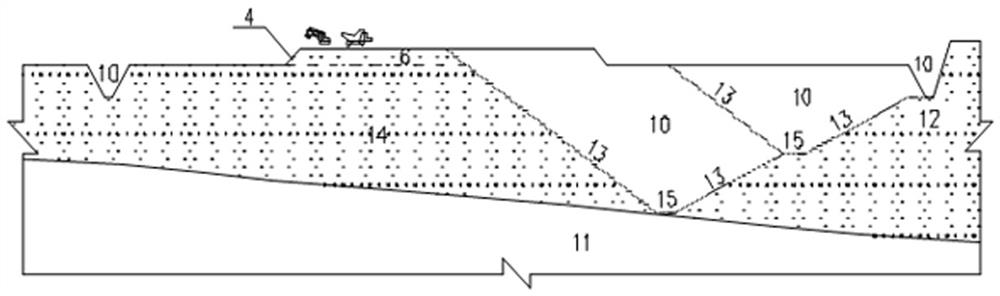

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] Such as figure 1 , figure 2 As shown, a valley type tailings reservoir of the present invention is based on the tailings dry mining method of groundwater drainage, comprising the following steps:

[0029] Step 1) Investigation of tailings pool: Divide tailings 14 into dry beach area 1 and water catchment area 2. Systematic investigation of water accumulation in water areas to provide basic data for tailings dry mining;

[0030] Step 2) Geological survey of the tailings pond: Carry out drilling exploration on the dry beach area 1 of the tailings pond to grasp the tailings quantity, quality and dryness of the tailings pond;

[0031] Step 3) Mining area division and parameter determination: based on step 1) and step 2) the mining area 3 is divided based on the consideration of ore quantity, tailings quality, dryness and wetness, mining elevation, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com