Refrigeration system instant freezing chamber storage control method and refrigeration system

A technology of refrigeration system and control method, which is applied in the direction of household refrigeration equipment, cooling fluid circulation equipment, lighting and heating equipment, etc., and can solve the problems of increasing wind speed or air volume, uneven temperature drop, supercooling, shallow supercooling, etc., to achieve Increase cooling capacity and prevent ineffective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

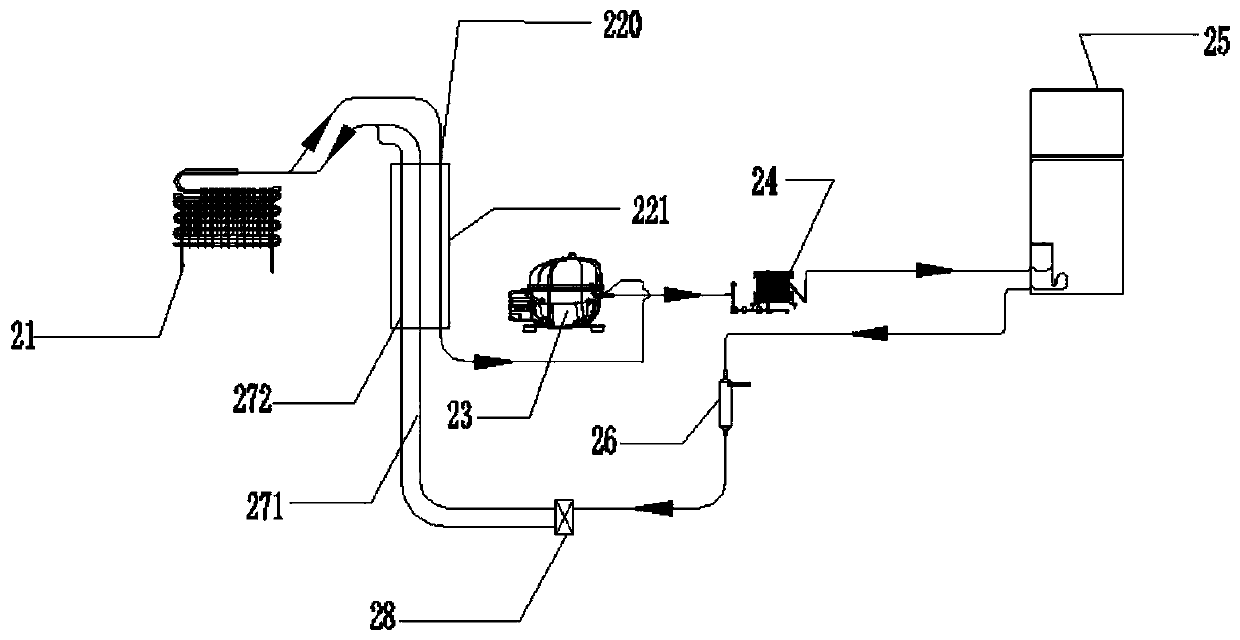

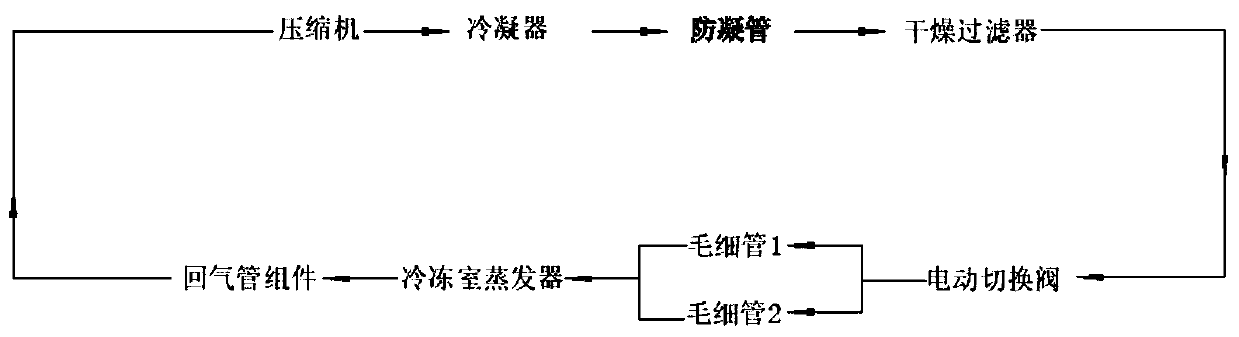

[0059] like figure 2 What is shown is that this embodiment provides a refrigeration system that implements any control method of the present invention. This system includes but is not limited to the following components: refrigerated evaporator 21, return air pipeline assembly 220, return air heat exchange section 221, compressor 23, condenser 24, anti-condensation pipe 25, dry filter 26, capillary 1-271 , capillary 2-272, electric switching valve 28.

[0060] like image 3 As shown, the flow direction of the refrigerant when the refrigeration system is working is: compressor 23 → condenser 24 → anti-condensation pipe 25 → dry filter 26 → electric switching valve 28 → capillary 1-271 or capillary 2-272 → freezing Evaporator 21 → return air pipe assembly 220 → compressor 23 .

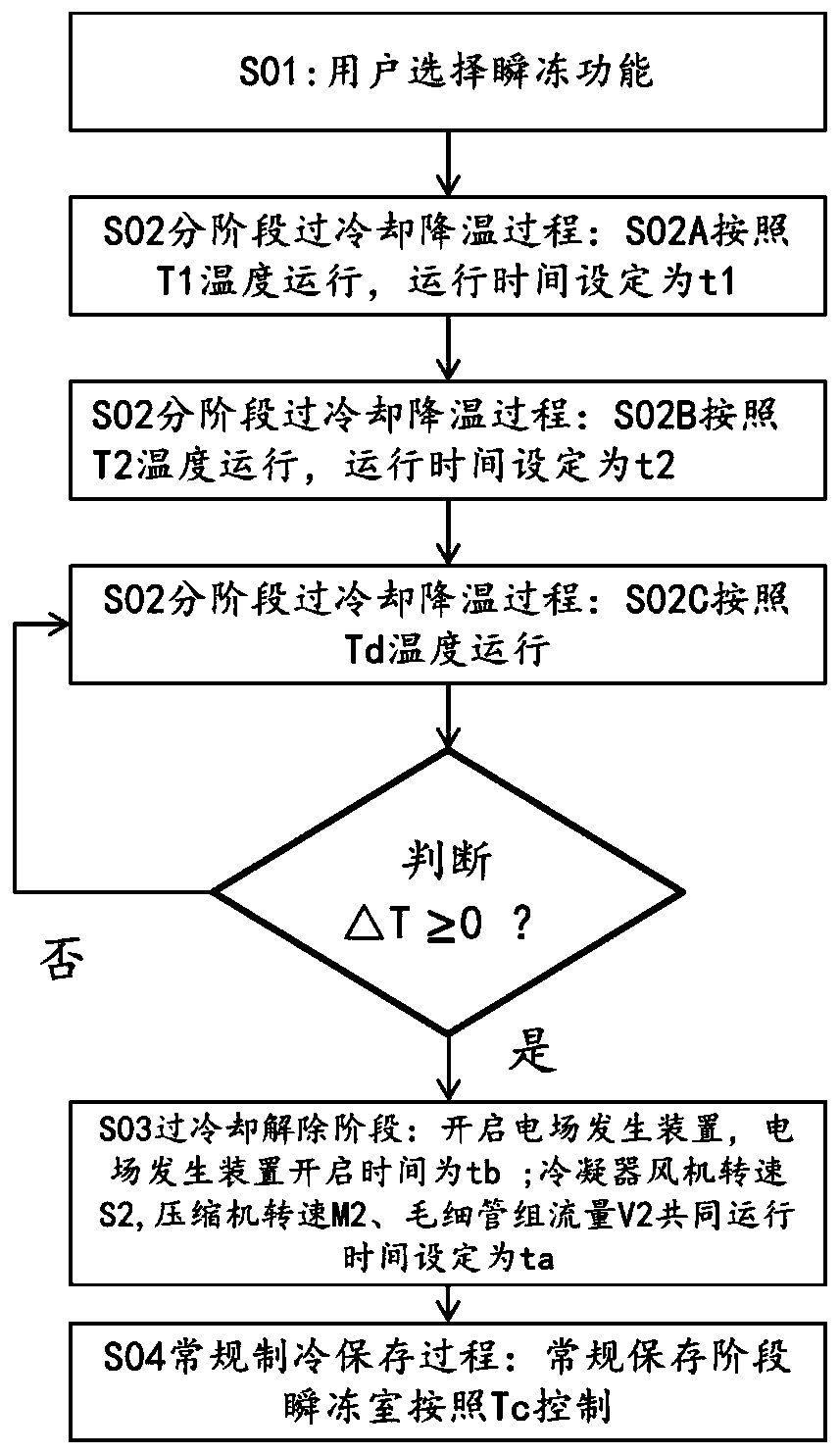

[0061] like Figure 4 As shown, the refrigeration system implementing any control method in this embodiment can be a refrigerator, and the refrigerator includes a refrigerator compartment 11 , an in...

Embodiment 2

[0121] It should be noted:

[0122] attached Figure 7 Schematic embodiment 2 is that S02C monitors to ΔT=(T at the 3rd cooling stage i -T i ') ≥ 0 An example of performing an operation for supercooling release. As would be understood by those skilled in the art, stage 4 or other stages are also possible. In this application, the monitoring of food temperature can be performed in real time or at intervals. In embodiment 2, when being monitored for the first time, ΔT=(T i -T i ') ≥ 0, with the first preset time interval τ 1 Monitor; for the first time, △T=(T i -T i ') ≥ 0, with the second preset time interval τ 2 The food temperature is detected m times again, only all △T of the first to m+1th detections satisfy △T=(T i -T i ')≥0 to execute the overcooling release procedure. Otherwise, the overcooling process is continued until the overcooling condition is met.

[0123] However, it is more valuable to monitor after the first stage of cooling is completed, because t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com