A near-expiration date marking device

A marking device and timer technology, applied in the medical field, can solve problems such as inconvenient auxiliary records, inability to remind items of expiration date, inability to provide recording paper, etc., to achieve the effect of convenient extraction and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

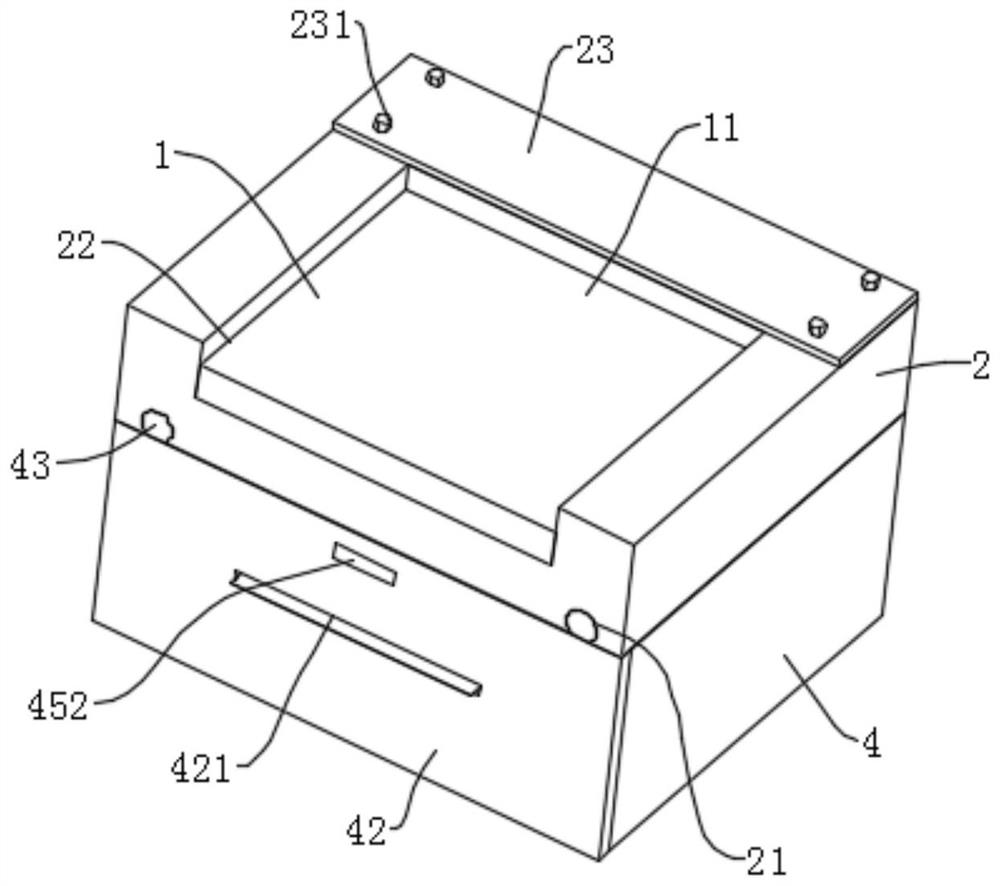

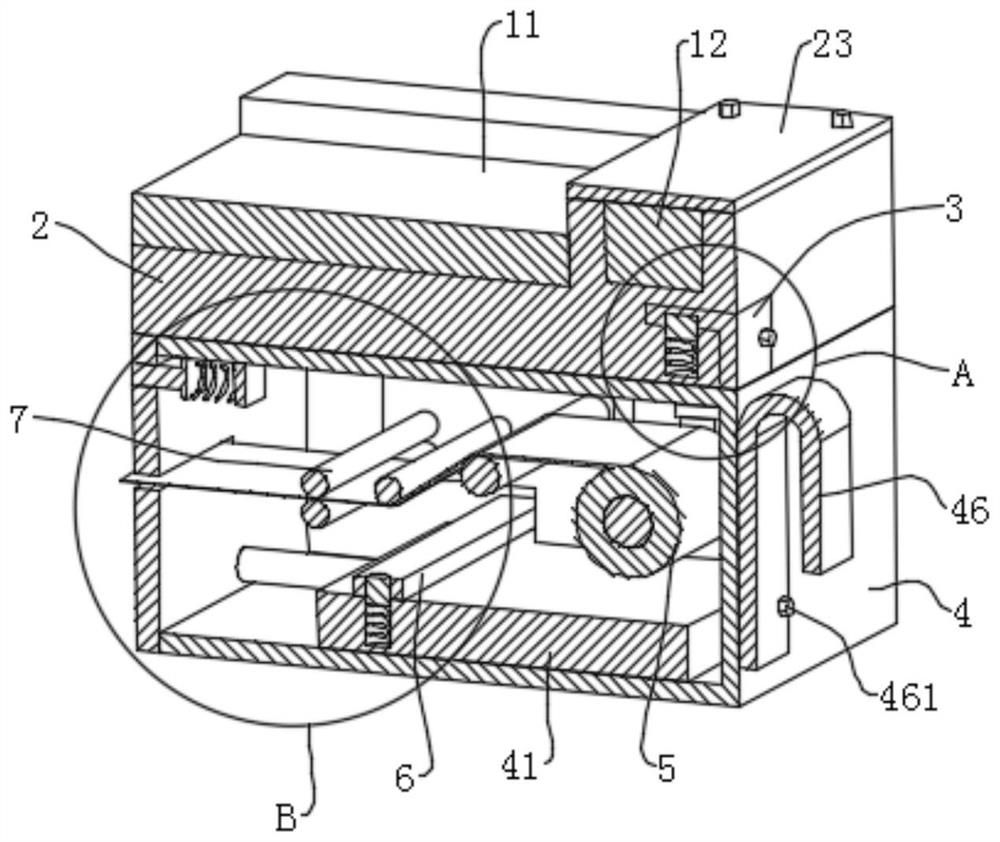

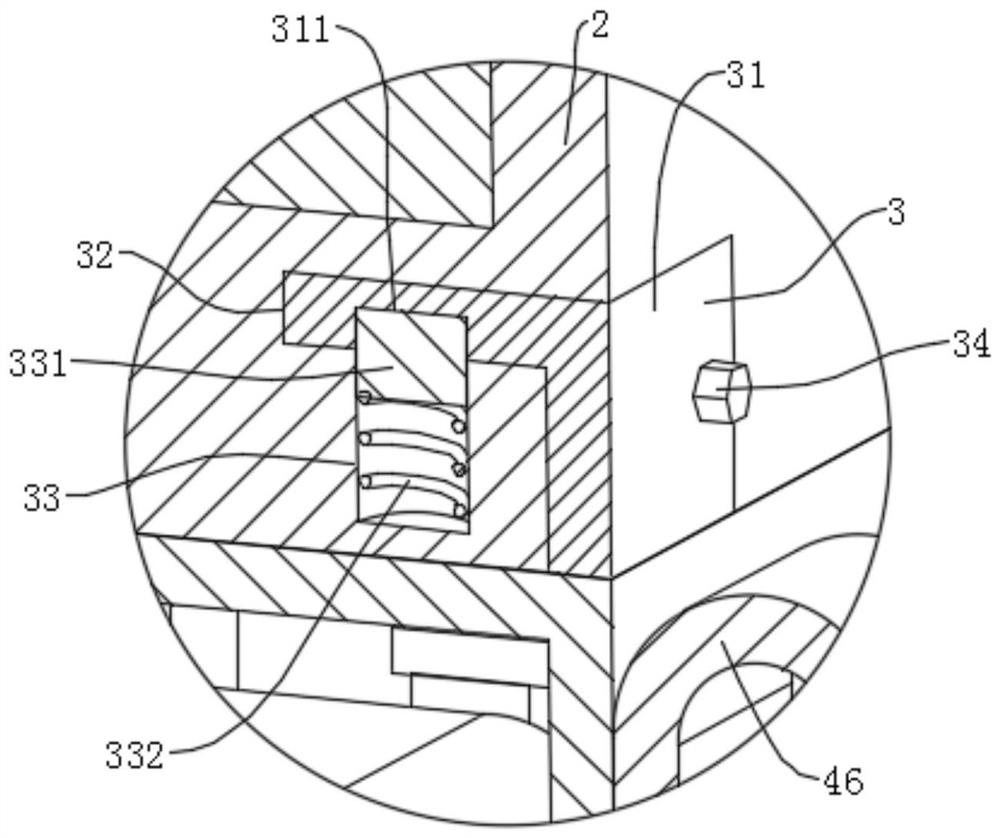

[0045] refer to figure 1 and Figure 5 , a near-effective date marking device, in order to use the device to realize the function of reminding the near-effective date, an electrochromic device 1 is arranged in the device; wherein the electrochromic device 1 includes an electrochromic glass 11, a timer 12, a DSP control device 13 and forward and reverse commutation pulse power supply 14, electrochromic glass 11, timer 12 and forward and reverse commutation pulse power supply 14 are connected in series in the circuit by wire, the control input terminal of DSP controller 13 and timer 12 The electrical connection between the control output terminal of the DSP controller 13 and the positive and negative commutation pulse power supply 14 is used to control the positive and negative output commutation of the positive and negative commutation pulse power supply 14; Reminder of the expiration date, when the timer 12 is used to set the time, after reaching a certain time node, the DSP ...

Embodiment 2

[0059] The difference from Embodiment 1 is that: a layer of antifouling coating is sprayed on the surface of the body 2 . Because the body 2 is easy to accumulate dust, in order to facilitate the cleaning of the accumulated dust, it is coated with an antifouling coating on its surface, wherein the antifouling coating is prepared by the following method:

[0060] Take the following raw materials of each component by weight for later use: 80 parts of polyethylene granules, 80 parts of polypropylene granules, 60 parts of tannic acid, 40 parts of acrylic acid, 40 parts of sodium citrate, 40 parts of disodium edetate, alkane 20 parts of alcohol amide, 10 parts of 2-hydroxyethylamine, 10 parts of ketene, 10 parts of pentaerythritol;

[0061] S1. Preparation of the first prefabricated solution: Mix tannic acid, acrylic acid, sodium citrate, disodium edetate, alkanolamide, and 2-hydroxyethylamine evenly, heat the overall temperature to 80°C, and heat for 5 minutes , so as to obtain t...

Embodiment 3

[0067] The difference from Example 2 lies in the preparation of the antifouling coating on the surface of the body 2, wherein the antifouling coating is prepared by the following method:

[0068] Take the following components by weight as raw materials for future use: 85 parts of polyethylene granules, 85 parts of polypropylene granules, 60 parts of tannic acid, 40 parts of acrylic acid, 45 parts of sodium citrate, 45 parts of disodium edetate, alkane 20 parts of alcohol amide, 10 parts of 2-hydroxyethylamine, 10 parts of ketene, 10 parts of pentaerythritol;

[0069] S1. Preparation of the first prefabricated solution: Mix tannic acid, acrylic acid, sodium citrate, disodium edetate, alkanolamide, and 2-hydroxyethylamine evenly, heat the overall temperature to 83°C, and heat for 5 minutes , so as to obtain the first preformed liquid;

[0070] S2. Prepare the second preformed liquid: add ketene and pentaerythritol into the first preformed liquid obtained in S1, and cool to norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com